- 37 -

When lubricate the chisel, the hammer must be standing upright against the chisel with enough down

pressure applied to force the chisel into the hammer. This will prevent excessive grease getting into the

impact chamber which could cause the hammer to lose power due to cushioning, or to stop operating due to

a hydraulic lock in the impact chamber.

Failure to lubricate the hammer regularly will reduce the life of the chisel, the chisel bush and front bush.

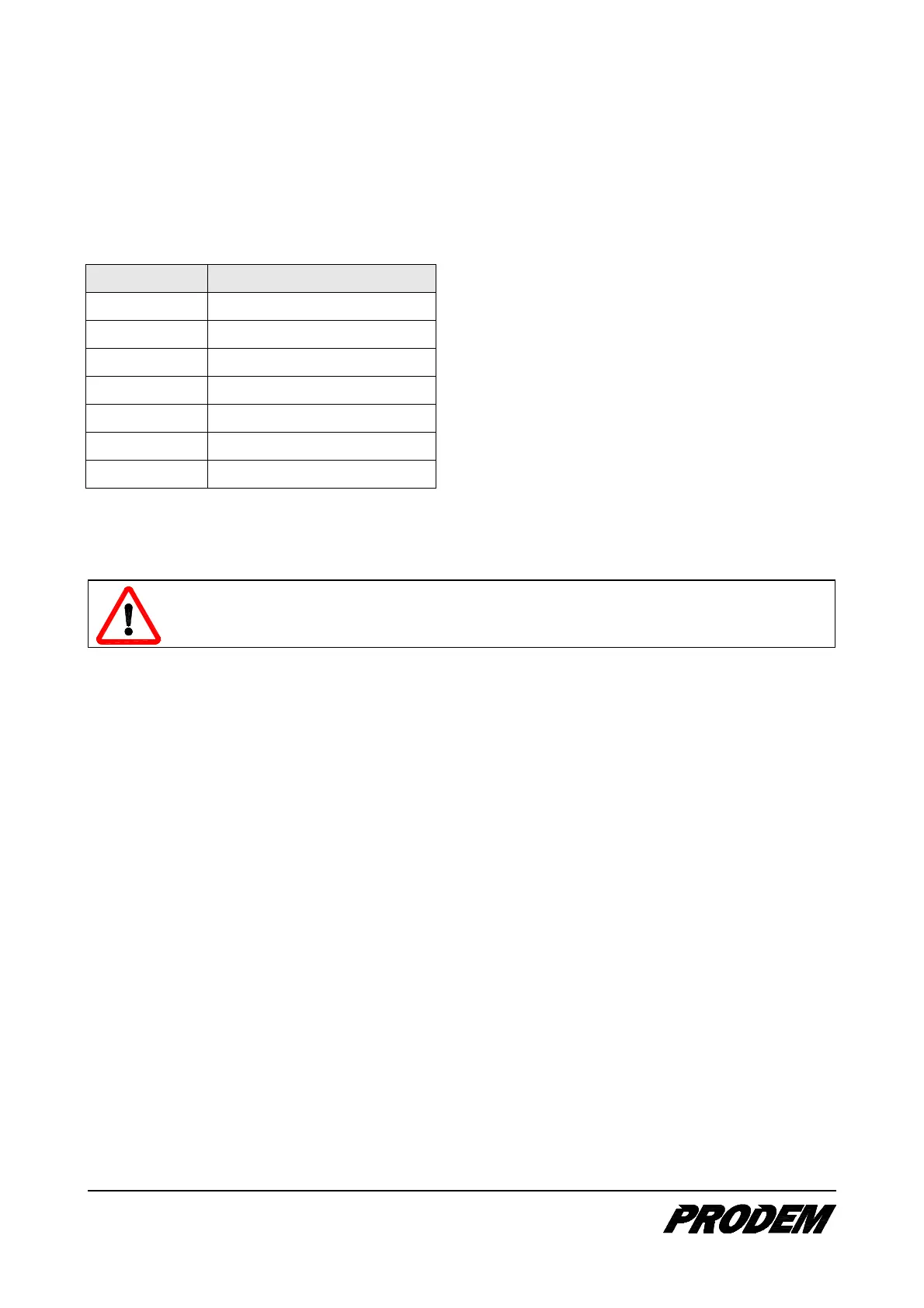

Recommended grease products by makers:

For other than those recommended consult PRODEM or our dealer prior to use.

7.5. Gas

DANGER!

Using other gases could result in an explosion. Use pure nitrogen; 99.8% purity, only.

The PRODEM hammer is a gas assisted type hydraulic hammer. The gas prefilled in the back-head gives

strong impact power and the gas prefilled in the accumulator decrease the pressure fluctuation in the

hammer. For this type of hammer, operating performance of hammer is under the control of the gas pressure.

Therefore, the charging pressures in these gas chambers are very important factor in the hammer and must

always be maintained within the specified limits(refer to Section “

4. Technical specifications

”).

This section describes how to fill the gas and check the gas pressure in the back-head and accumulator of

your hammer. Use only pure nitrogen of 99.8% purity and ensure that no other gas, e.g. air or oxygen is

used. Gas charging kits should be on hand all the time, to allow the following checking and maintenance

work to be performed.

7.5.1. Checking and charging the gas in the back-head

If the impact power of the hydraulic hammer starts to drop, the gas pressure in the back-head should be

checked.

The back-head need not to be refilled until the gas pressure has decreased to below the specified value. In

general, checking the back-head gas pressure recommended at least every 50 hours or weekly. And, Refill

the gas if necessary.

Note:

When checking or charging the gas pressure, always lay the hydraulic hammer flat without any contact force

applying to the chisel. The gas pressures should be checked with the hammer at the ambient temperature

before operating or at the gas temperature of 60°C to 70°C (140 to 158°F) after operating.

Maker Grease Product Name

CALTEX MULTIFAC EP2

CASTROL SPHEEROL EP2

ESSO RONEX MP2

GULF CROWN EP2

MOBIL MOBILUX EP2

SHELL ALVANIA EP2

TOTAL MULTIS EP2

Loading...

Loading...