32

WP-250 General

Operating Instructions

The PROFAX Welding Positioner is designed for light loads, with a maximum load of 250 lbs. when the table is in a vertical position and 440

lbs. when it is in the horizontal position.

Loading the Positioner

The positioner may be floor or bench mounted. When mounting the positioner on a bench it is advisable to secure it solidly to the bench to

avoid any possibility of tipping over with a load. See figure 1 for mounting dimensions.

When loading the work piece onto the table it is important that the following guide lines are followed to avoid over turning the positioner and/or

overloading the motor and gear train.

1. Determine the total weight of your work piece including all fixtures, chucks, brackets, etc.

Note: This must not exceed 250 lbs. with the table in the vertical position or 440 lbs. with the table in the horizontal position.

2. Locate the center of gravity of the work piece with any fixtures attached.

3. Mount the work piece to the turn table making sure that the center of gravity is within 4” of the center of the turn table as shown in figure

No. 2.

Warning! Use equipment of a proper size to lift and/or move the weldment onto the positioning table. Falling equipment can cause personal

injury and/or equipment damage.

Welding Cable Ground (Work) Connection

The positioning table is grounded by means of a brush which contacts the underside of the table. See Figure 3. Connection to this is by

means of a welding cable lug. Attach the welding cable lug to a properly sized welding cable and then attach the lug to the brush holder by

means of the bolt provided. Tighten the bolt securely. The brush has a maximum allowable welding current of 200 amps. Do not attempt to

run higher than 200 amps through the grounding brush. Welding currents greater than 200 amps should be grounded directly to the work

piece by means of a proper ground clamp.

Service or repair of this unit must be done by qualified personnel only.

Warning! Before performing any maintenance on this control circuit disconnect the unit from any power supply.

®

®

®

®

Figure No. 2

Figure No. 3

Turn Table in Vertical PositionTurn Table Face

4” Radius

4”

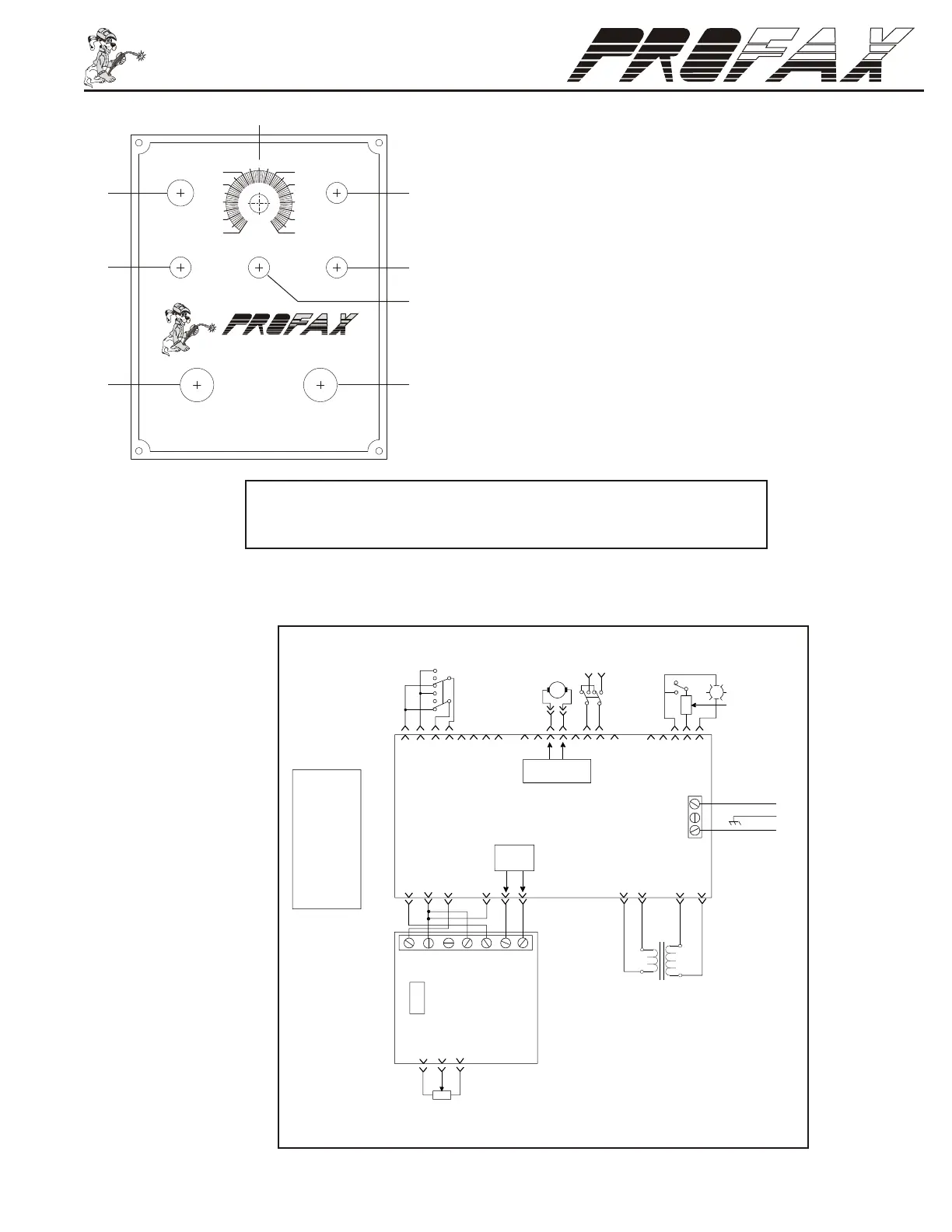

Control Panel & Wiring Diagram

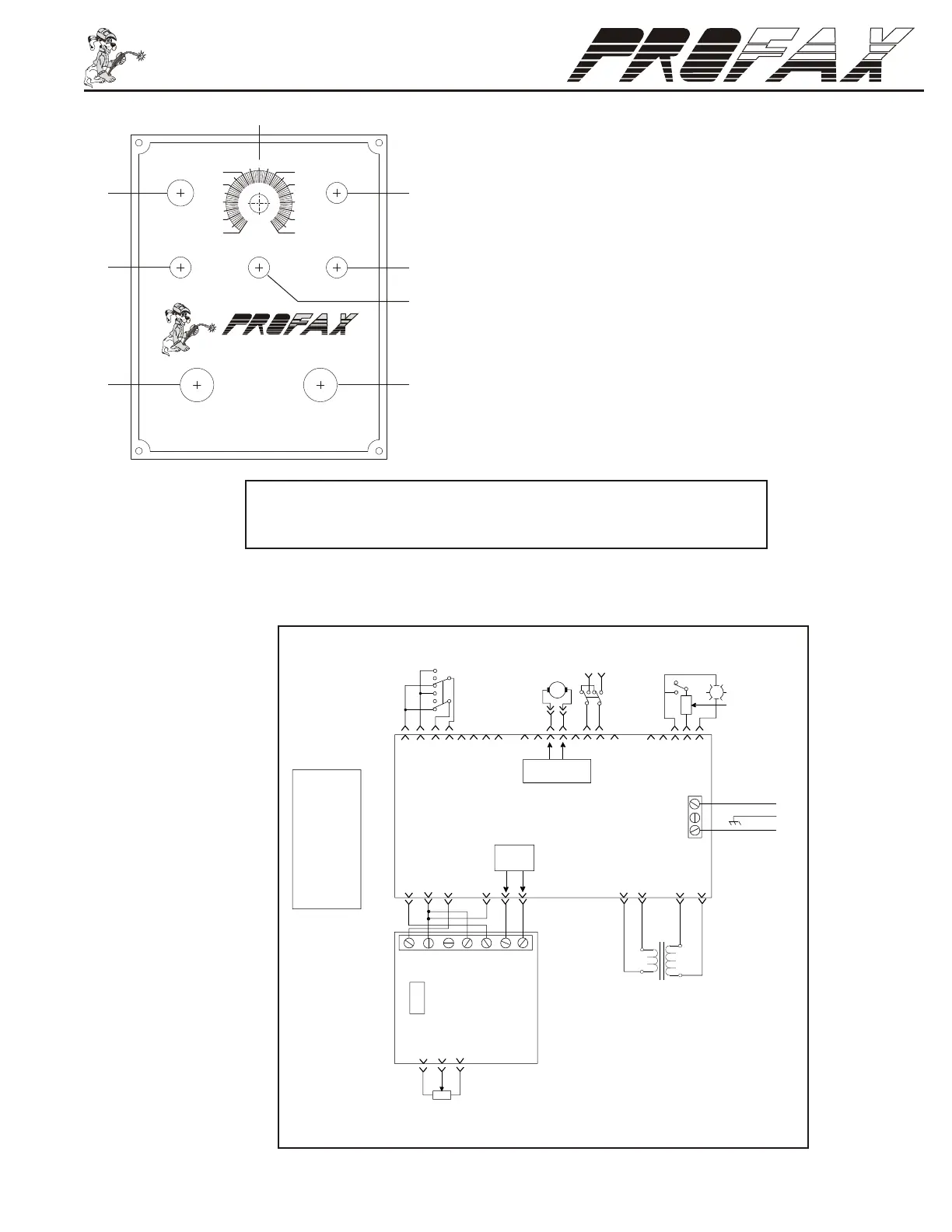

Wiring Schematic

1. Pilot Light: Lights up red to indicate power on.

2. Power On-Off Switch

3. Speed Control: Provides control of table rotation speed from 0%(0 RPM) to

100%(5 RPM).

4. Fuse Holder: Fuse 5 amp

5. Forward/Off/Reverse Switch: Controls table rotation. Forward (clockwise

rotation) and Reverse (counterclockwise rotation).

6. Remote/Panel Switch: Remote = Start and stop are remotely controlled.

Panel = Start and stop are operated from the control box.

7. Remote Plug: Plug-in for the foot switch to start and stop of the turn table

rotation.

8. Power in

0

10

20

30

40

POWER

FUSE

50

100

90

80

70

60

ON

OFF

FOOT SWITCH

FORWARD

OFF

REVERSE

POWER IN

®

®

REMOTE

SPEED

PANEL

Do Not Switch Under Load

1

2

3

4

5

6

8

7

CAUTION! - Switching rotation direction before coming to a complete

stop may damage motor and/or gear box voiding warranty.

5K

1

2

U

U

GG Y

R

W W

S

KB

O

OB

F

1

G

W

R1

U

P

N

W

O

C

L1

F-

F+

A-

A+ L2

F

2

CT

Y

Min Max

125V

4A

PC2

L1

B

Line

Gnd.

Line

L2

CN1

CN2

CN6

PC1

M

P

Off

On

125V / 5A

B

0 to90VDC

w / Ref. to R1

115VAC

to PC2

15VAC

B = Black

G = Green

K = Pink

N = Brown

O = Orange

P = Purple

R = Red

S = Gray

T = Tan

U = Blue

W = White

Y = Yellow

Forward

Off

Reverse

CN3

CN5

CN4

RC1

Panel

Remote

115VAC for WP250

or

220VAC for WP250-2

Loading...

Loading...