16

www.equalizerhitch.com

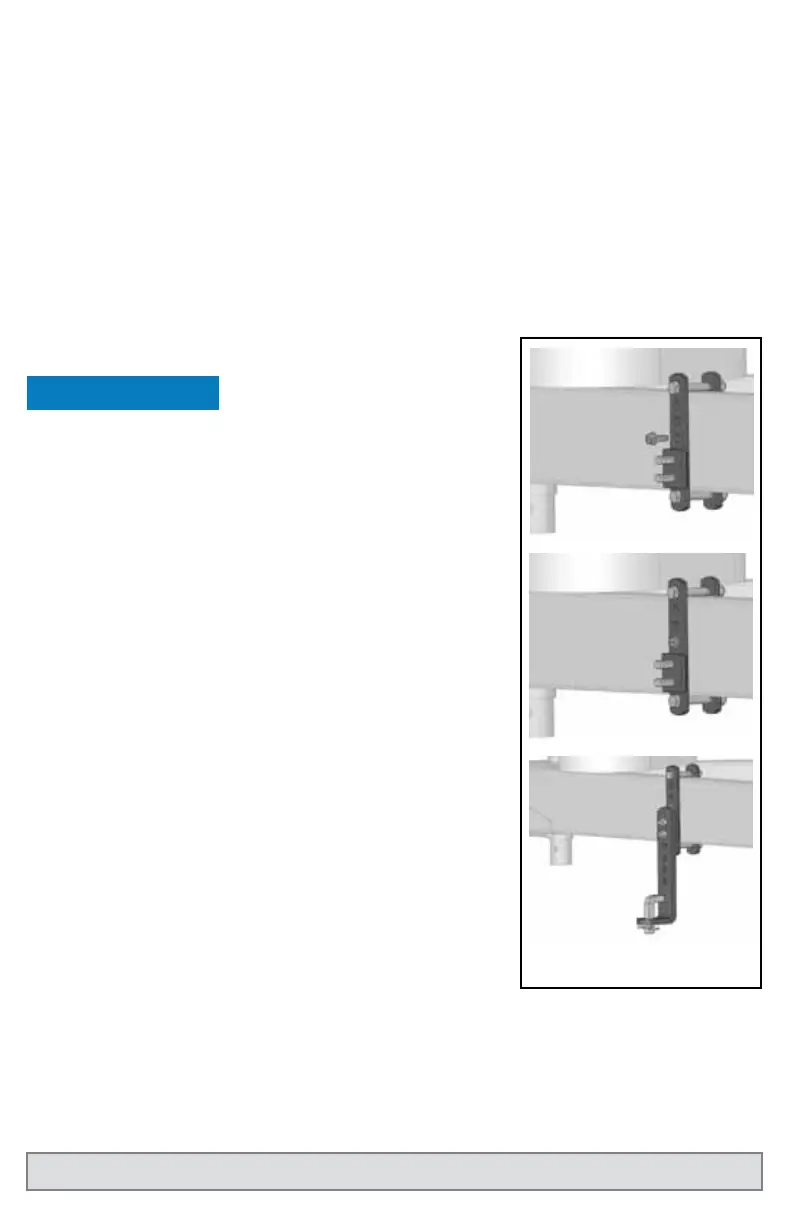

Pinch the inside and outside link plates tight to the trailer frame so that

both lay at against the frame. Inside link plates are sometimes slightly

bowed from the manufacturing process. If this is the case, the center of the

bow should be placed toward the trailer frame so that as they are tightened

they atten out against the frame

Continue holding them in place while you hand tighten both nuts. Use

wrenches to nish tightening the link plate bolts until they are snug, alter-

nating from top to bottom 1/2 turn at a time. Bolts and nuts should be fairly

tight, but do not over tighten them. Link plates must be at against the trailer

frame to work correctly. Uneven or over tightening may cause link plates to

bow and “walk” along frame. See Figure 8.

Do not use impact wrench to tighten link plate

or L-bracket bolts.

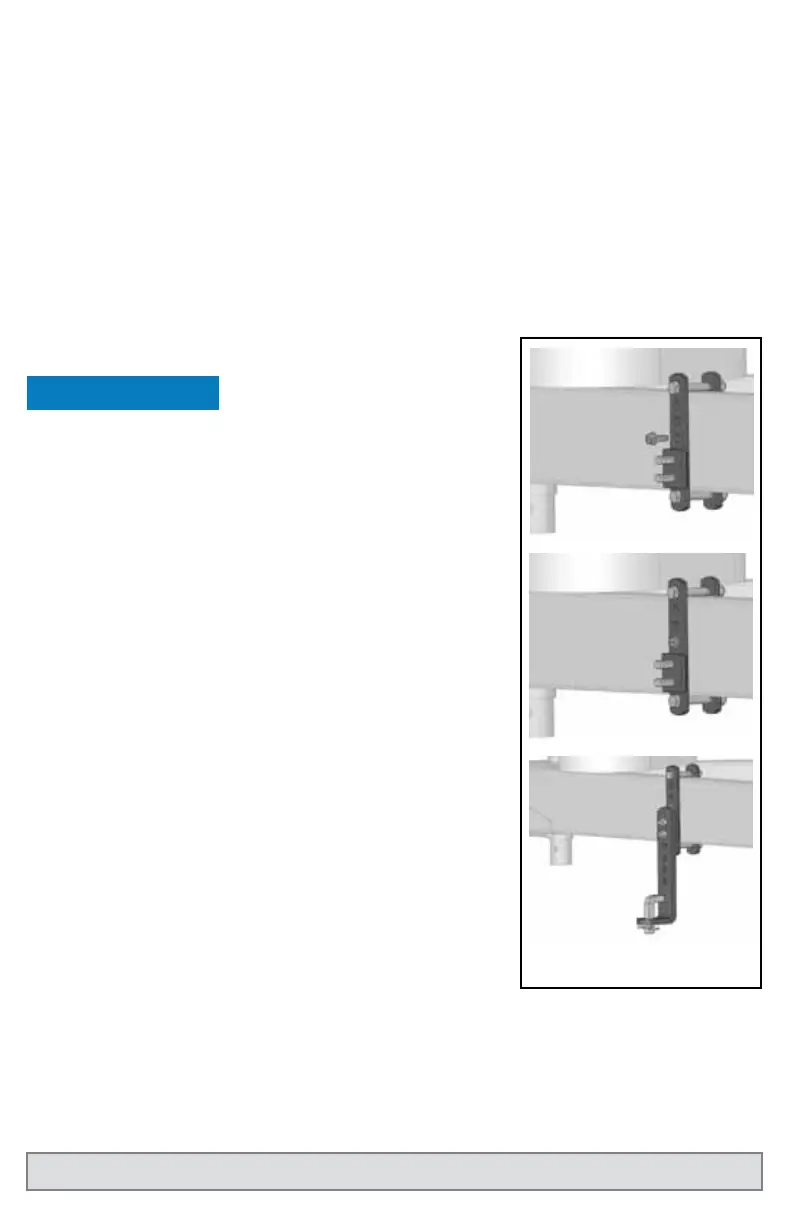

Once the inverted brackets are installed

correctly – use a 3/8” x 1” self-tapping washer-

head bolt to secure each outside link plate against

the frame (see gure 7d). This bolt (95-03-5610)

may be obtained from Progress Mfg. Inc.

Locate the hole in the outside link plate that

is nearest the center of the trailer frame (bottom

of the four holes). Using a center punch, make

a mark on the frame through the center of this

bracket hole. Then, drill an 11/32” hole at this

location. You may want to use a smaller drill bit

rst to make a pilot hole.

After completing the 11/32” hole, install the

3/8” x 1” self-tapping washer-head bolt. Tighten

the bolt until it is snug against the bracket. Be

careful not to over tighten and break the bolt.

Slide the L-brackets onto the link plate studs with the spring arm

plate facing away from the trailer. For the initial setup, leave 2 holes

showing at the top above the studs and two below. They may need to be

adjusted up or down later. Thread on the nylock nuts and tighten them.

Figure 7d

Loading...

Loading...