N 93-602-00 Issue 1 Page 9 of 10 © Protec Fire Detection PLC 2015

5.0 Faults

The ProPointPlus monitors various aspects of the unit to ensure the unit is fully operational. During faults the

fault LED will illuminate and the buzzer will sound a slow pulse tone. Listed below are the diagnosed faults

indicated on the unit.

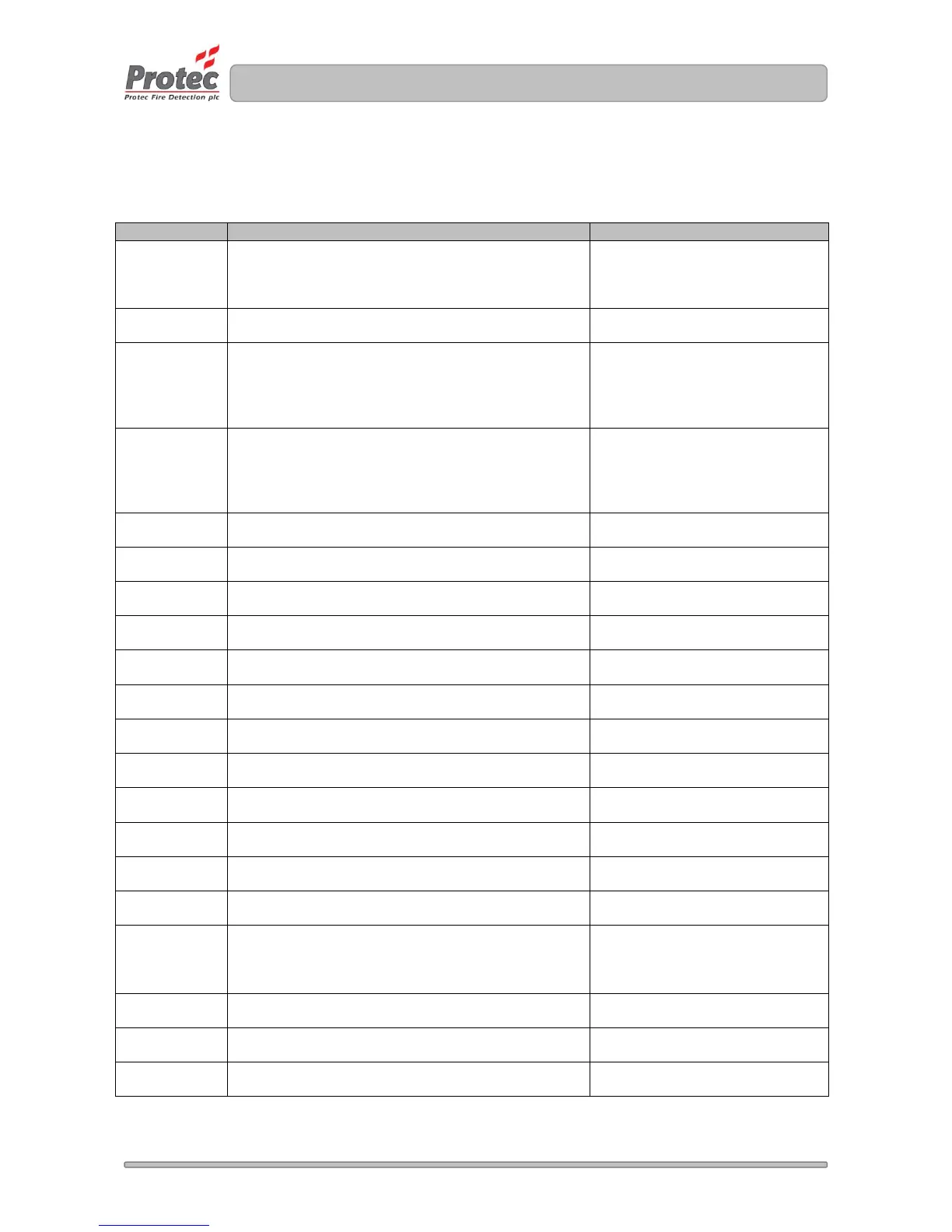

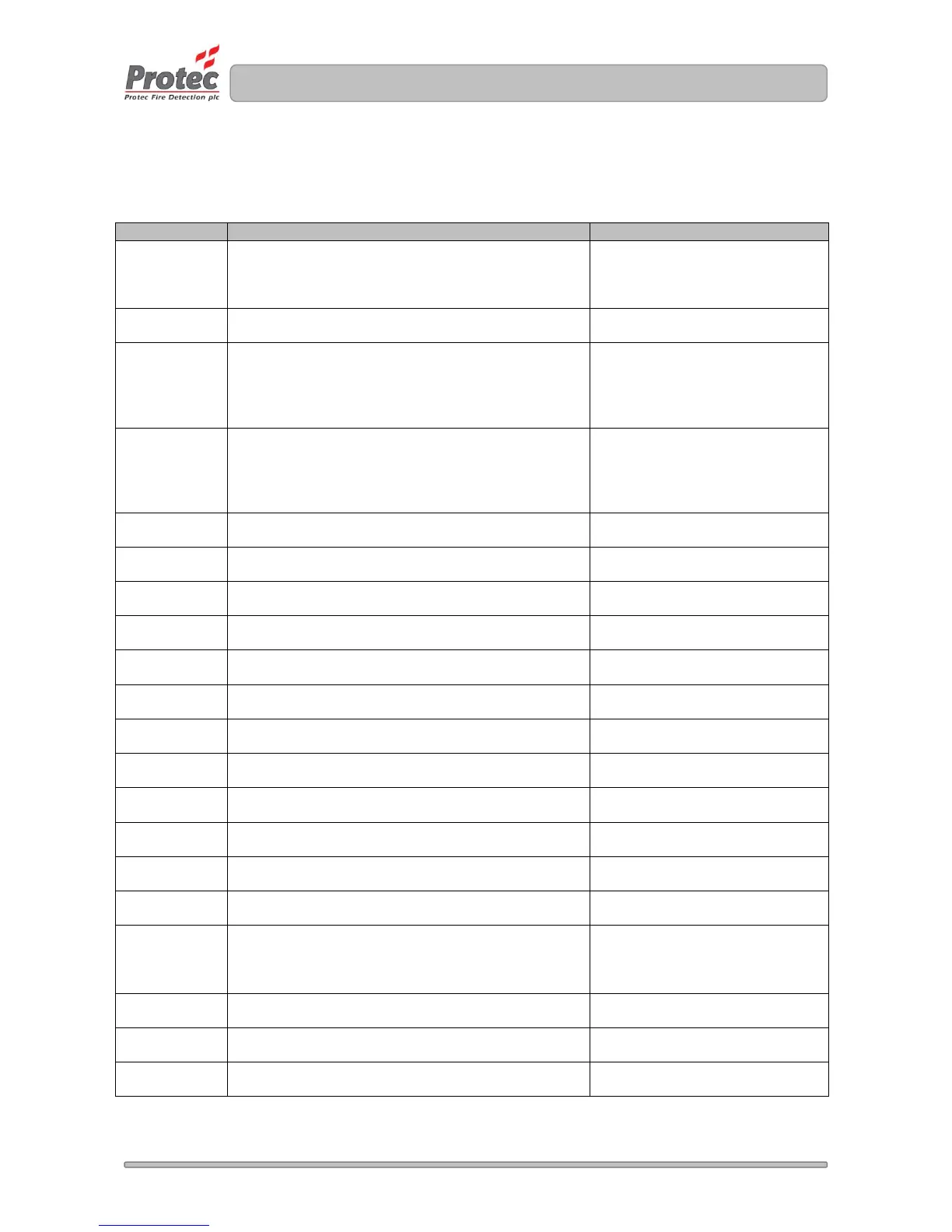

Table 1 System Faults

A communication problem to a device within the unit

has been detected or a device has been removed

from the unit.

Check the device in fault is fitted

correctly otherwise contact a

Protec operative or a Protec

distributor.

A new device has been added to the unit but the

device has not been commissioned.

Contact a Protec operative or a

Protec distributor.

The airflow measurement has moved outside the

acceptable tolerance range either by an increase or

decrease in normalised airflow.

Check sampling pipe installation

is correct as per commissioning,

ensure no pipes are blocked.

If fault persists contact a Protec

operative or a Protec distributor.

The supply fault monitoring input is reading low.

Typically connected to the external power supply

charger unit.

It may be necessary to look at the

power supply charger unit to

determine the cause of the fault.

If fault persists contact a Protec

operative or a Protec distributor.

The optical value has increased outside the normal

operation range.

Contact a Protec operative or a

Protec distributor.

The optical value has decreased outside the normal

operation range.

Contact a Protec operative or a

Protec distributor.

The data (RS485) path has failed.

Contact a Protec operative or a

Protec distributor.

The inputs ‘check to test’ option is active, activated

using the ProView.exe PC software.

Contact a Protec operative or a

Protec distributor.

Internal settings are outside the expected values.

Unit will default to factory settings.

Contact a Protec operative or a

Protec distributor.

The supply voltage to the unit is below the operating

value (<19V

DC

).

Contact a Protec operative or a

Protec distributor.

Web server file is corrupt.

Contact a Protec operative or a

Protec distributor.

The SCD calibration offset value is out of limits.

Contact a Protec operative or a

Protec distributor.

The SCD optical LED is damaged.

Contact a Protec operative or a

Protec distributor.

A pipe airflow is set to be ignored, activated using the

ProView.exe PC software.

Contact a Protec operative or a

Protec distributor.

The SCD Carbon Monoxide (CO) cell has expired its

life capacity or is missing.

Contact a Protec operative or a

Protec distributor.

The fan is damage or under/over performing.

Contact a Protec operative or a

Protec distributor.

Either the SCD(s) have been individually disabled or

the isolate input is active.

If used check external input

isolation equipment. Otherwise

contact a Protec operative or a

Protec distributor.

The heat thermistor reading is out of range.

Contact a Protec operative or a

Protec distributor.

The manufacturing details have not been stored in

the unit.

Contact a Protec operative or a

Protec distributor.

An incorrect SCD device fitted in the unit.

Contact a Protec operative or a

Protec distributor.

Loading...

Loading...