5 (13)

SERVICE INSTRUCTION

K 82, 85, 101, 102, 104, 151, 155

K82/85/101/102/104/151/155.58.0211.Eng/Digital

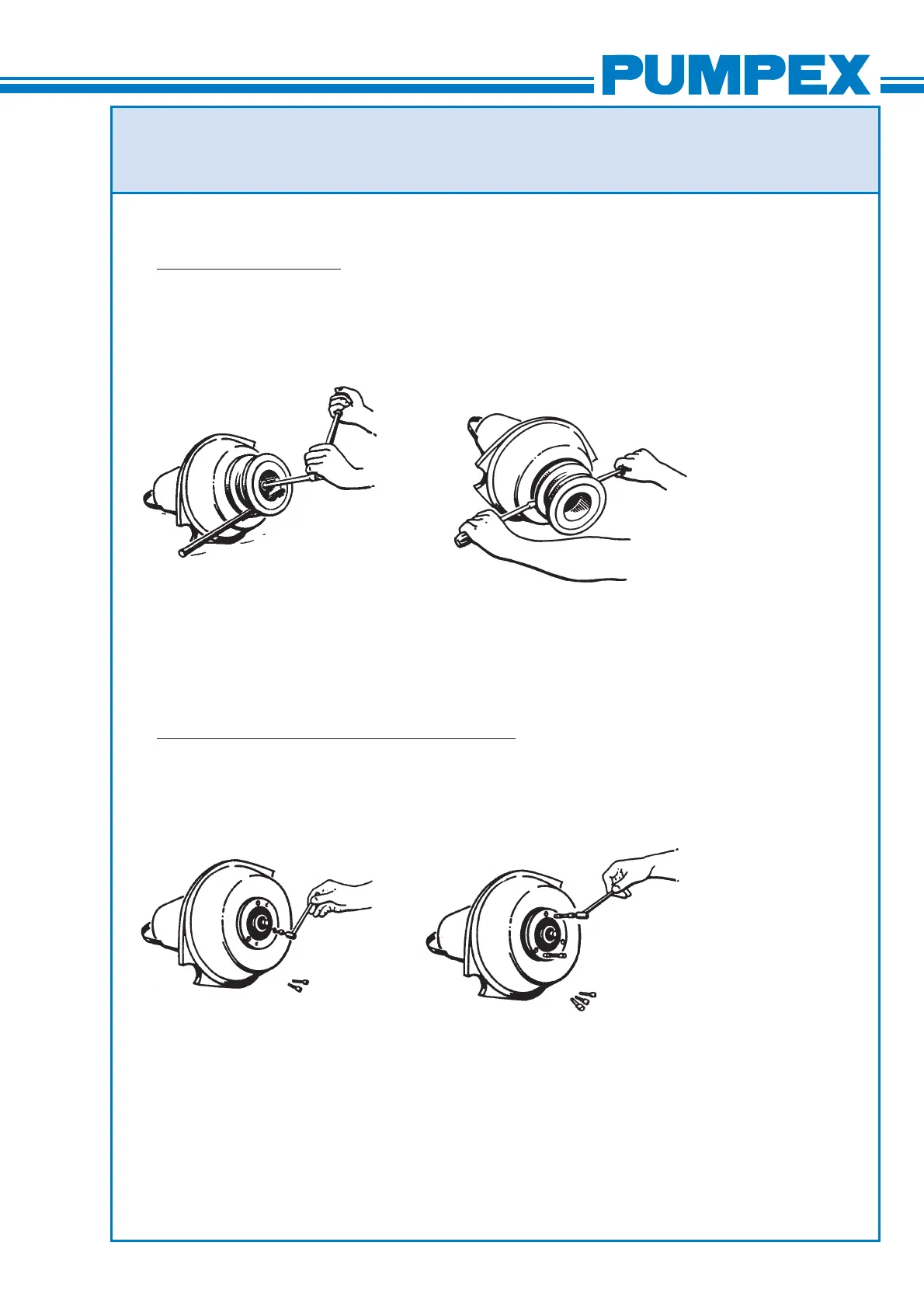

Removal of Impeller

The impeller is fitted on a cylindrical shaft end. To simplify the

loosening of the impeller nut, place a piece of wood (pipe or

similar) inside the impeller to keep it from rotating. Loosen the

impeller nut with a socket wrench (sockets 19 and 24 mm res-

pectively).

The impeller has a relatively light fit on the shaft and is using a

flat key. The impeller can be removed by using two (2) large

screwdrivers as pry bars.

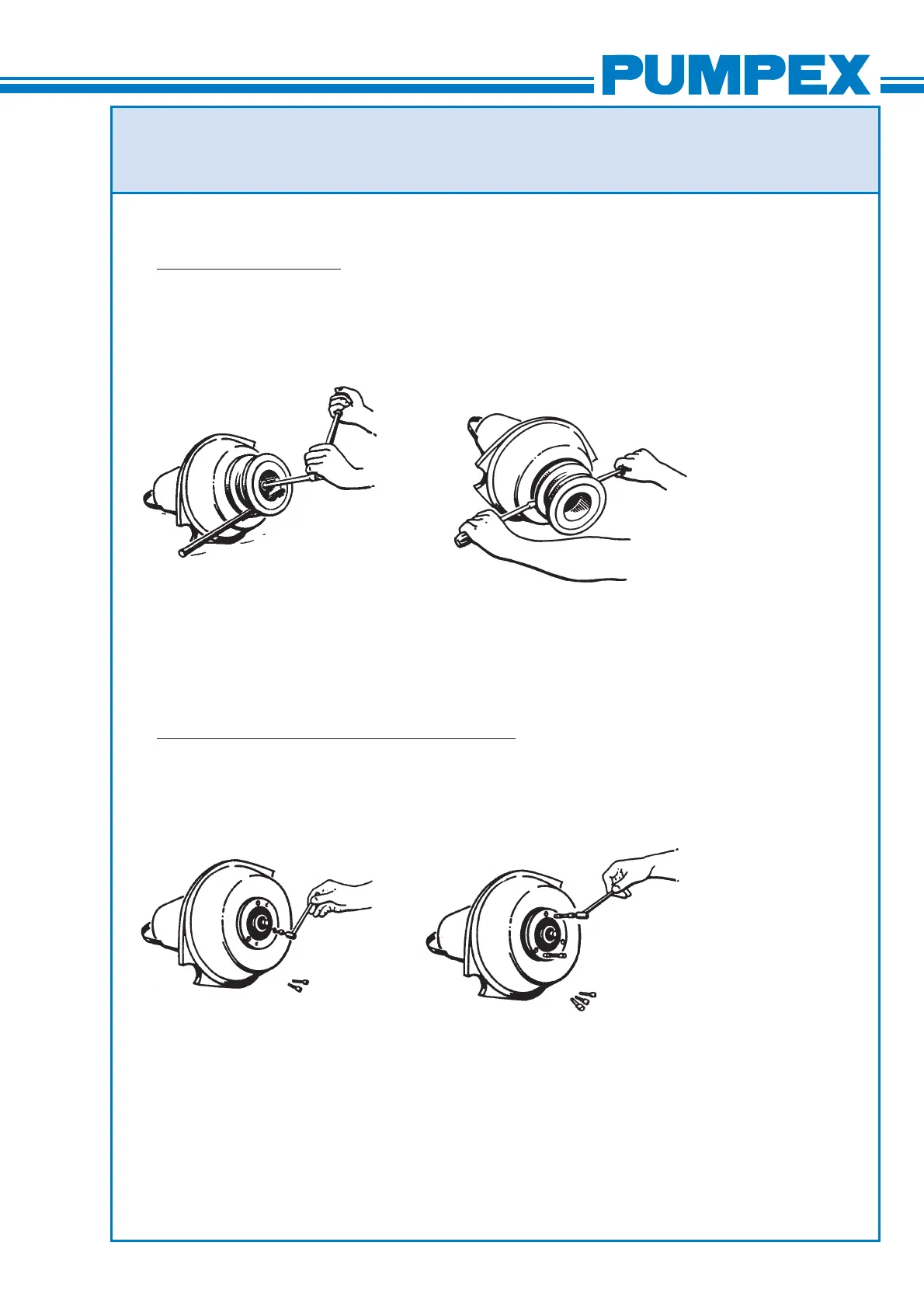

Removal of Mechanical Shaft Seal Unit

Remove the three (3) screws holding the seal unit to the oil

housing bottom. The seal unit flange is provided with threaded

holes. Clean the holes with a small screw driver (or tap M 6).

Remove seal unit by using two M 6 screws, approximately 40

mm in length, fitted into the threaded holes. By turning the screws

evenly the seal unit will back off from the oil housing bottom.

A defective seal unit should always be replaced. The defective

seal unit should be sent to the nearest service point in exchange

for a rebuilt unit.

Loading...

Loading...