EN

BTR185 INSTALLATION AND USE MANUAL - REV009A

33

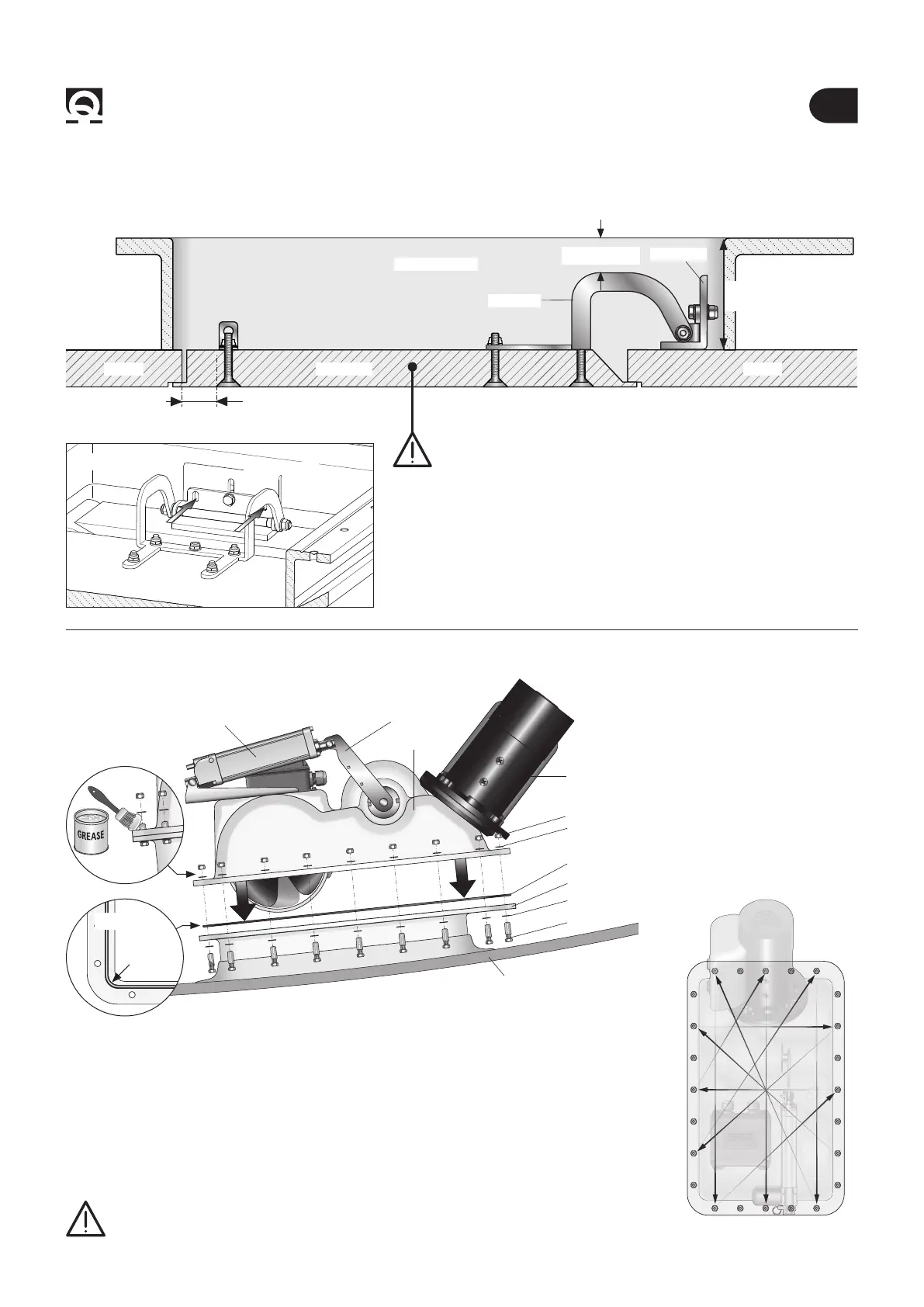

BTR1854 - Installation

Fig. 14

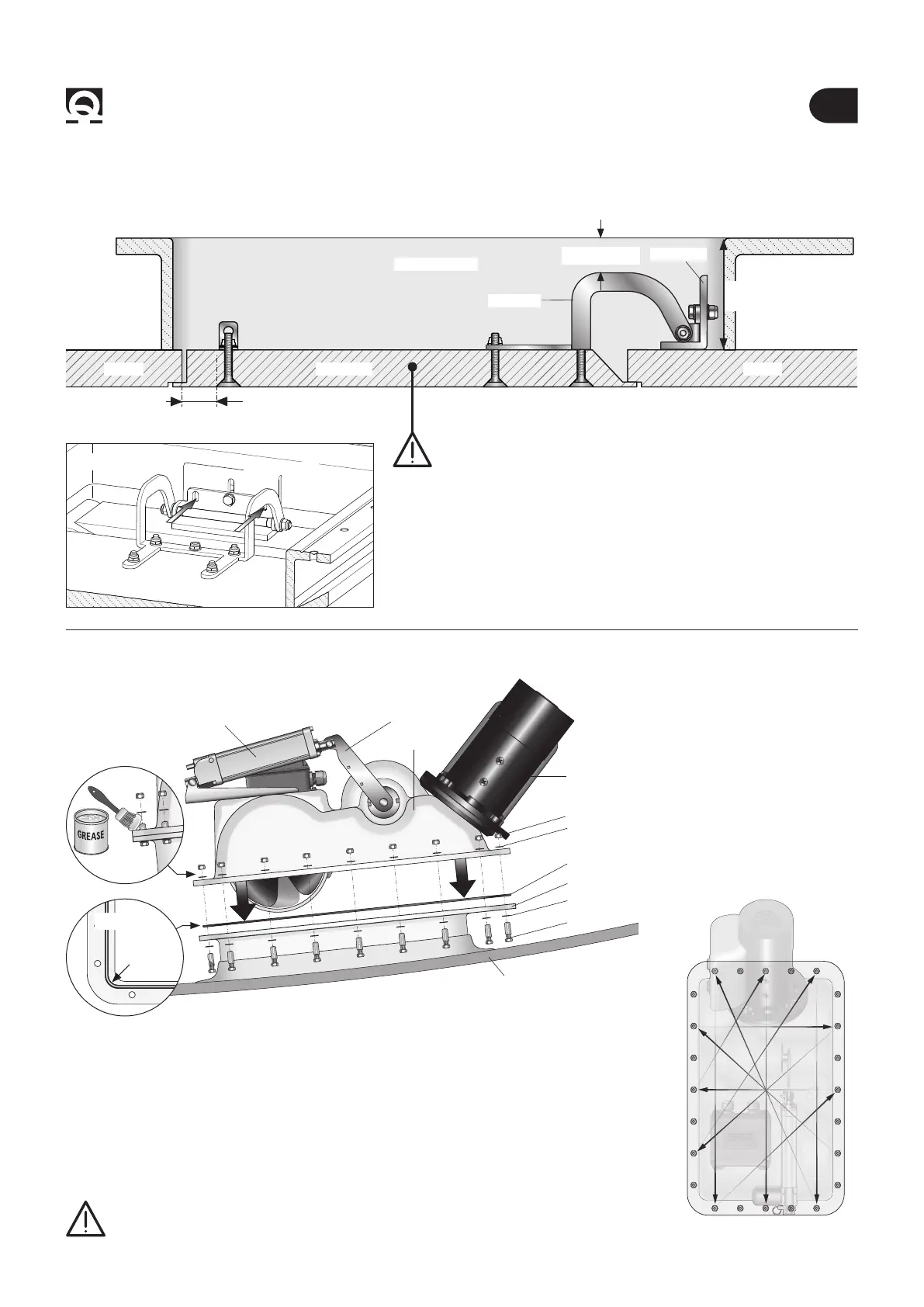

4.3 - Thruster’s installation

Fig. 12

15 mm

LID

Min. 80 mm

COUNTER FLANGE

HINGE

ANGLE BAR

HULLHULL

• Drill the angle bar and fasten securely with the other two M8 screws

(g. 13).

N 2 SCREWS M8

Fig. 13

WARNING: in order to allow a stable xing of hinge and bracket,

the lid must present neither empty areas nor non-structural llings

inside (g. 12).

Min. 5 mm

• Remove the adhesive backings, previously applied, from the counter ange.

• Make sure the area where the gasket will be positioned is clean and has not suffered

any damage during installation.

• Position the o-ring on the counter ange (part. 14A), assemble the thruster (g.14),

spread marine grease on the thread of the bolts (g.14B) and fasten securely with sup-

plied screws.

O-RING

BOLT

WASHER

MOTOR

WASHER

NUT

COUNTER FLANGE

HULL

THRUSTER

F

The bolts and screws of the counter ange must be tightened to 25Nm, tightening

little by little in a crossed sequence, following a scheme such as in the example in

gure 14C.

WARNING: about one week after installation, you should check that all screws are

properly tightened in order to compensate for any potential o-ring settling.

ACTUATOR

ACTUATOR

HANDLE

Fig. 14C

1

2 3

10 9

4

8

7

12

11

6

5

Part. 14B

O-RING

Part. 14A

Loading...

Loading...