MAINTENANCE INSTRUCTIONS

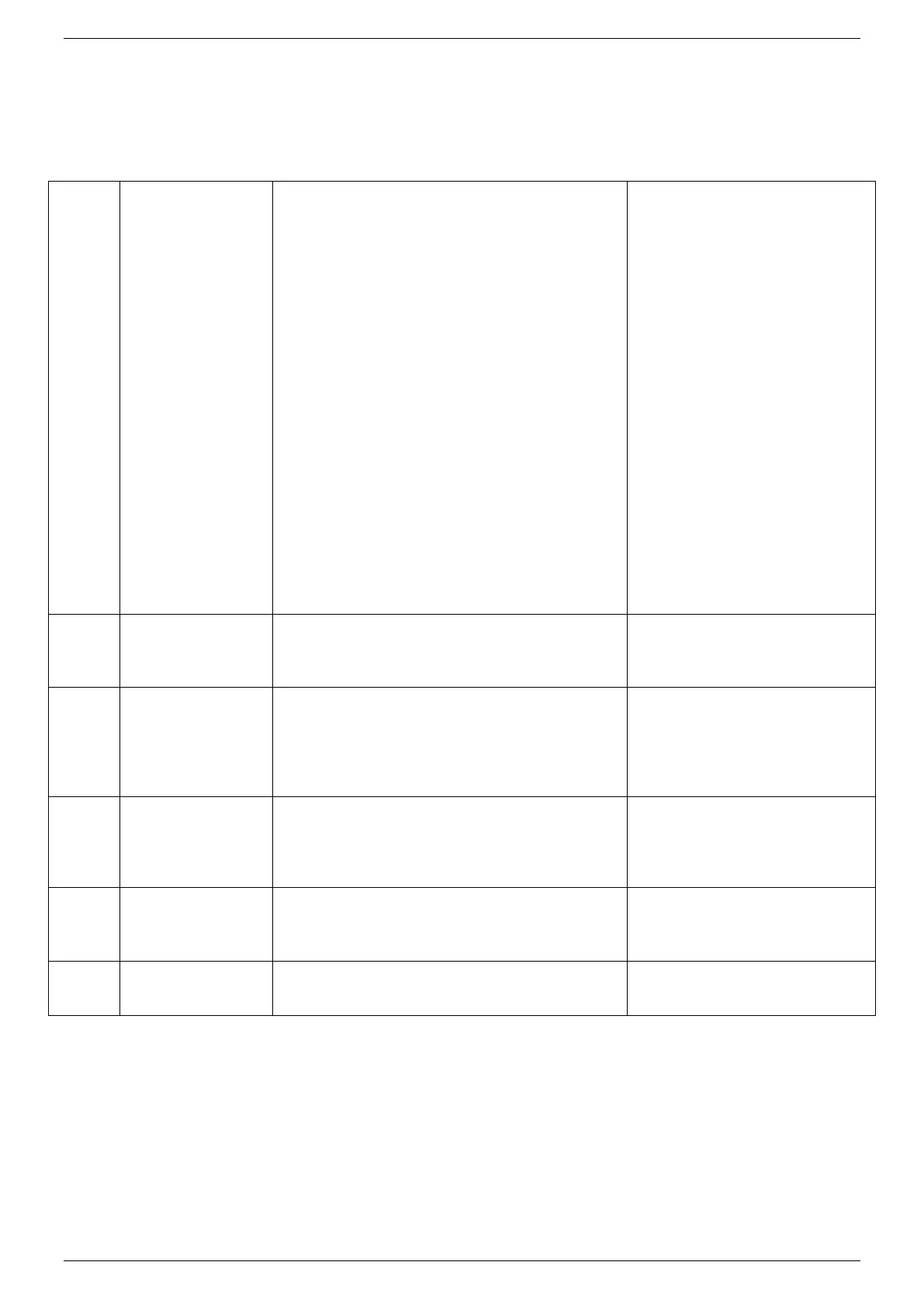

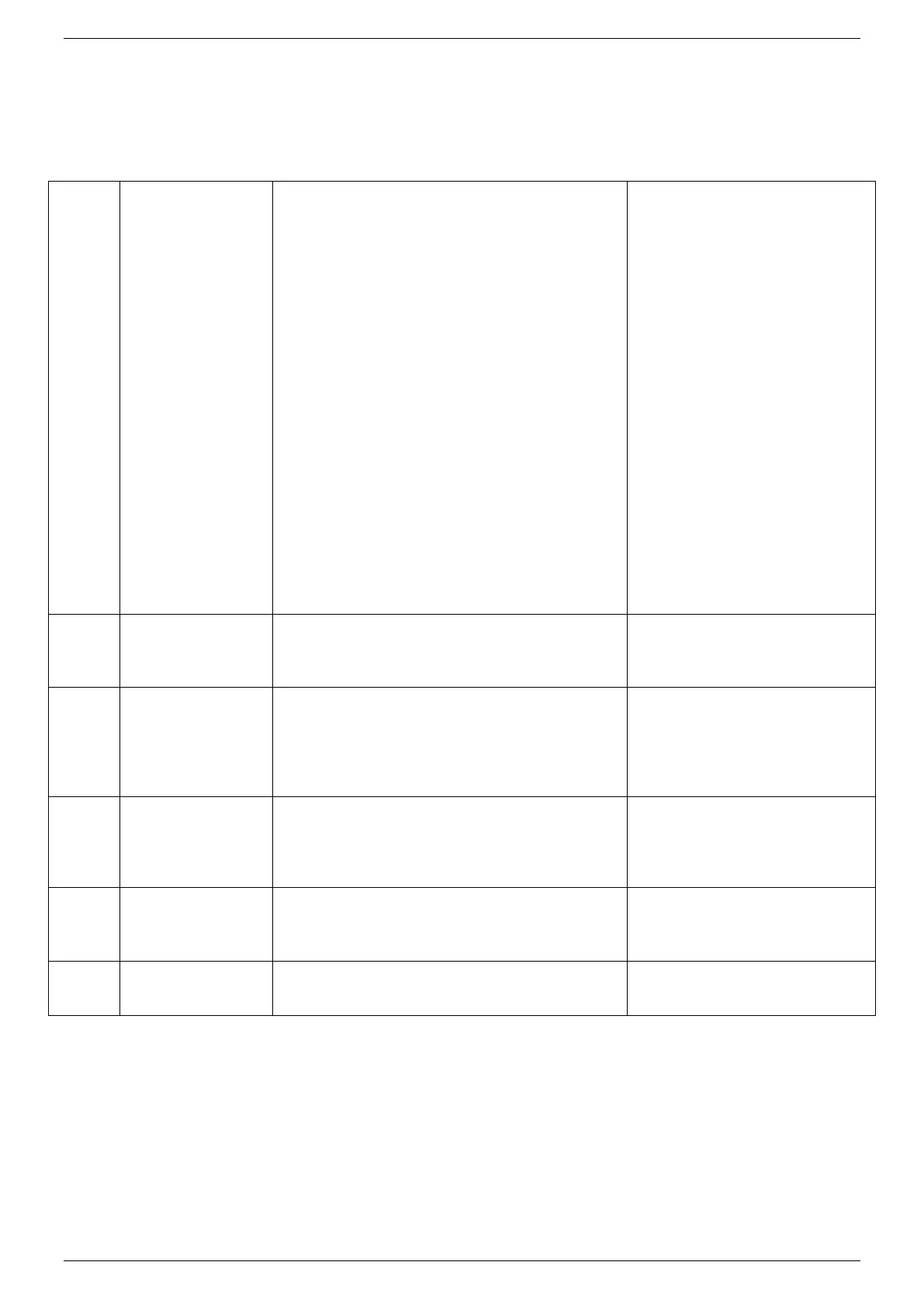

6.6 Troubleshooting

E01

NO FLAME

WITH NO IGNITION

a. NO GAS.

b. IGNITION ELECTRODE BROKEN OR

EARTHED.

c. GAS VALVE MALFUNCTION

d. MECHANICAL MINIMUM ADJUSTMENT (ON

GAS VALVE) SET TOO LOW OR SLOW

IGNITION ADJUSTMENT SET TOO LOW.

e. GAS VALVE INLET PRESSURE TOO HIGH

(FOR LPG BOILERS ONLY );

WITH IGNITION

f. POWER SUPPLY LIVE AND NEUTRAL

WIRES INVERTED.

g. IONISATION ELECTRODE MALFUNCTION.

h. IONISATION ELECTRODE CABLE

DISCONNECTED.

a. CHECK MAINS SUPPLY.

b. REPLACE PART.

c. REPLACE PART

d.

REGULATE MECHANICAL

MINIMUM OR SLOW

IGNITION.

e.

PRESSURE SETTING.

f.

CONNECT THE POWER

SUPPLY WIRES

CORRECTLY.

g. REPLACE PART.

h.

ELECTRODE WIRE.

E02

SAFETY

THERMOSTAT

TRIPPED (95 °C)

i. THERMOSTAT MALFUNCTION OR OUT OF

CALIBRATION.

j. THERMOSTAT CABLE DISCONNECTED.

j. CHECK THE WIRING;

H20

SYSTEM

k. INSUFFICIENT WATER PRESSURE IN THE

SYSTEM (STOPS AT 0.3 BAR).

l. WATER PRESSURE SWITCH CABLE

DISCONNECTED.

m.

WATER PRESSURE SWITCH

MALFUNCTION.

l. CHECK THE WIRING;

m. REPLACE PART;

E05

HEATING SENSOR

n. SENSOR MALFUNCTION OR OUT OF

CALIBRATION (RESISTANCE VALUE 10

kOhms AT 25 °C).

o.

SENSOR CABLE DISCONNECTED OR

WET.

o. CHECK

CONNECTION;

E14

SWITCH

q.

INLET OR OUTLET FLUE GAS DUCTS

OBSTRUCTED

r. SWITCH CABLE NOT STABLE

q. CHECK FLUE GAS DUCTS

E22

PROGRAMMING

s. LOSS OF MICROPROCESSOR MEMORY.

PARAMETERS;

Loading...

Loading...