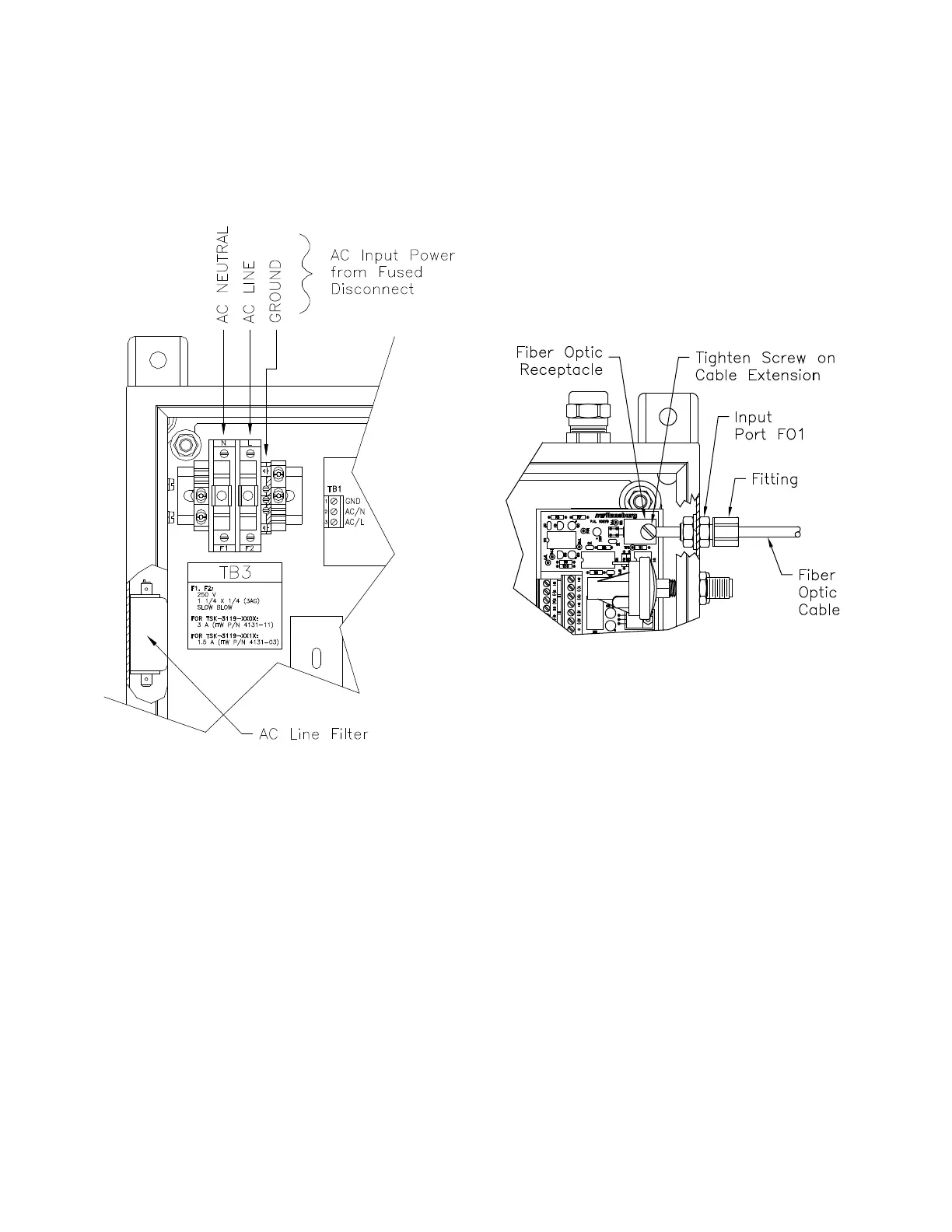

FIBER OPTIC CABLE

(See Figure 5)

Remove the tting from the ber optic input port

(FO1 - FO6) on the side of the control panel and

slide over one end of the ber optic cable. Open

the control panel door. Insert the end of the ber

optic cable through the input port tting and into

the hole of the black rectangular ber optic recep-

tacle on the ber optic receiver module. Tighten

the screw of the ber optic receptacle onto the at

of the cable extension and secure the tting on

the side panel. Route the ber optic cable to the

rotator and connect the other end of the cable to

the ber optic input tting of the rotator.

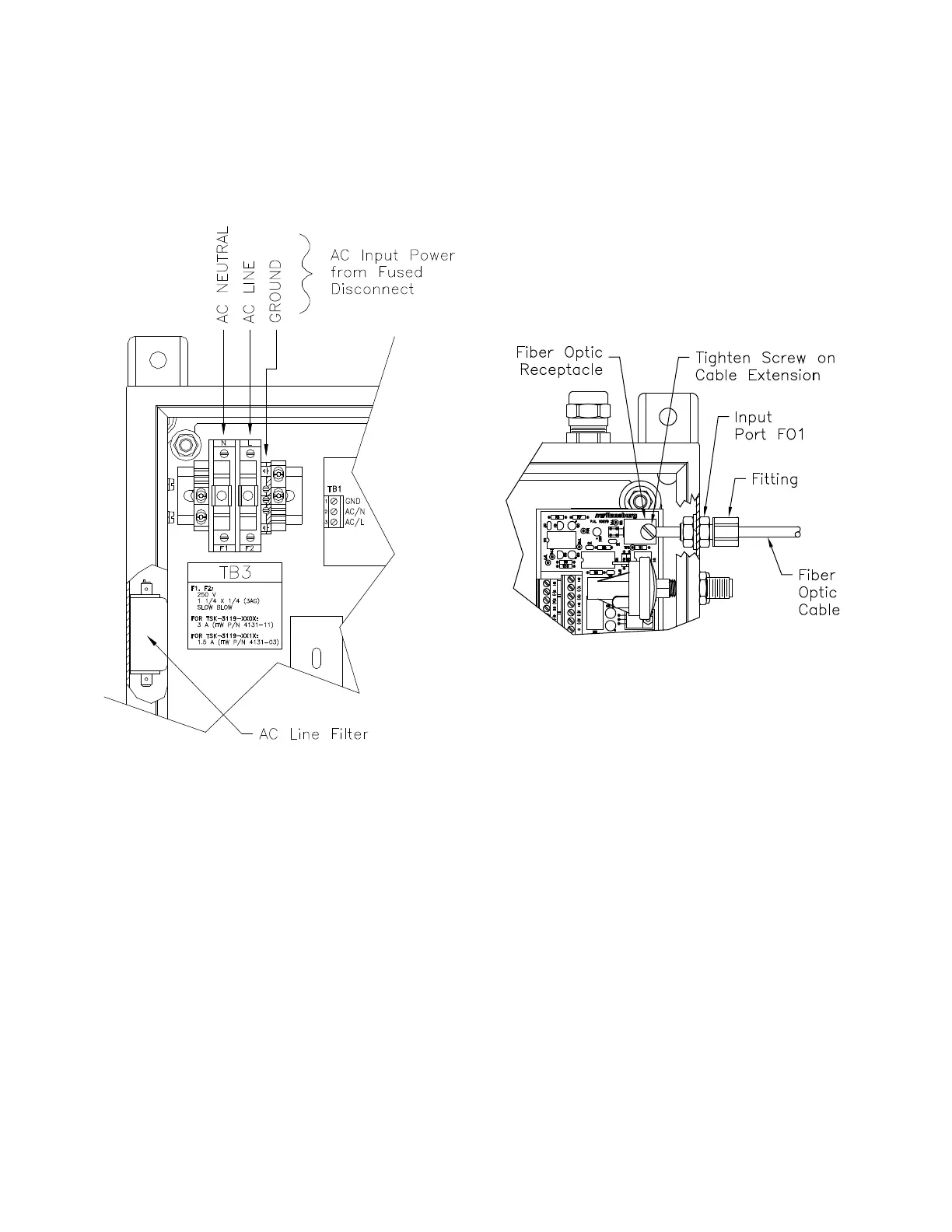

Figure 4: AC Input Power Connections

The ber optic cables are integrated into ¼” tubing

for mechanical protection. A minimum bend radius

of 3" is required. Care must be taken to prevent

kinking for protection of the ber optic cables.

Avoid exposure of the cable ends to chemicals

such as paint or solvents. Exposing the cable

ends to such chemicals will cause damage and

can severely reduce the ability of the cable to

transmit light.

The control panel is precongured for 115 VAC or

230 V AC depending on the model number. Refer

to the "Parts Identication" section of this manual

and the product specication label located on the

control panel.

PNEUMATIC

CONNECTIONS

(See Table 2)

All pneumatic connections are made to the right

side of the PulseTrack 2 control panel. System

components should be installed to minimize the

length of pneumatic control lines. This will max-

imize the rotator speed control response. Tubing

may exceed the maximum lengths as indicated in

the "Specications" in the "Introduction" section of

this manual dependent on the specic installation

requirements; however, this could degrade overall

speed control performance.

Figure 5: Fiber Optic Cable Installation

Loading...

Loading...