$%% !#%

$%#&% $

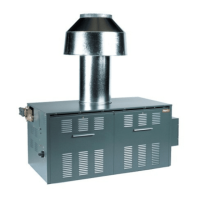

CATALOG NO. 2000.50AH Effective: 06-27-11 Replaces: 09-16-10 P/N 240035 Rev. 35

This manual should be maintained in legible condition and kept adjacent to the heater or in a safe place for future

reference.

:/07>G

%D;0

(%% * &$$

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas

supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

(# Improper installation, adjustment, alteration, service or maintenance can

cause property damage, personal injury or loss of life. Refer to this manual.

Installation and service must be performed by a qualified installer, service agency or

the gas supplier.

#* &#$%* Do not store or use gasoline or other flammable vapors and

liquids or other combustible materials in the vicinity of this or any other appliance. To

do so may result in an explosion or fire.

Installation and service must be performed by a qualified installer, service agency or

the gas supplier.

#,D?30=8F

0,?492

:470=>