SETUP & OPERATION

Page 12

SETUP & OPERATION

Basic Multi Boiler System Operation

For boiler system setup/installations

please refer to the 2008 ASHRAE Handbook, CH12 or later

revision.

A basic multi boiler system typically uses boilers of the

same size and type. With HeatNet, this includes (1) Master

and (1-15) Member boilers. The boilers are connected

together using an H-Net communications cable effectively

creating (1) boiler. This allows the system heating BTUs to

be evenly distributed amongst all of the boilers.

The Version 1.6 HeatNet board requires Minibus

connections for FlexCore boilers with more than (1) heat

exchanger. The Minibus requires a serial data cable between

each HeatNet Control board. The first and last Heat

Exchanger must have the minibus terminated for the bus to

work properly. S1 would be placed in the ON position as

indicated below for the front and rear heat exchangers. The

jumper, JS1 must always be in the position indicated

(closest to S1). It is used for testing.

Basic multiple boiler system

A basic multi boiler system can be configured using the

boiler menus to create custom systems/features. These

features are best described in the section: Default Settings

& Menu Item Description. Along with these menu items

are hardware support for many auxiliary functions.

Once the system has been properly setup (all default menu

values used and H-Net addresses assigned), the system is

enabled by placing the REMOTE/LOCAL switch to the

LOCAL position on the Master boiler. All Member boilers

must have their respective switches in the REMOTE

position. When the Master boiler’s Heat Demand input

(LOCAL switch) closes, the system becomes operational

and will fire as many boilers as it needs to maintain the

header water temperature’s setpoint. See the DHW section

to fire using two setpoints.

When a boiler is to be fired in a multi boiler system (header

water temperature is below the heating band), the Master

checks the HeatNet boilers it has available. Then the Master

checks if a Lead Boiler is to be used (LEAD BOILER > 0).

The Master boiler then looks at which type of firing rotation

it has selected: LOFO, FOFO, TRUE (runtime), or MIXED.

In our example we will use the TRUE (runtime) rotation

since it is the default.

The Master now checks all of the runtimes to determine

which boiler has the least runtime based on the MIN

RUNTIME setting in SETTINGS: FIRING MODE: The

MIN RUNTIME setting is the minimum runtime interval in

hours that is used to compare boiler to boiler runtimes.

Once the boiler designated to fire has been determined, the

Master sends the command over the H-Net cable to fire that

boiler and resets the ADD BOILER delay timer to prepare

for the next boiler to fire. If the header water temperature is

still below the heating band and the ADD BOILER delay

timer has expired to zero, the process is repeated until the

header water temperature enters the heating band.

When a boiler receives a command to fire:

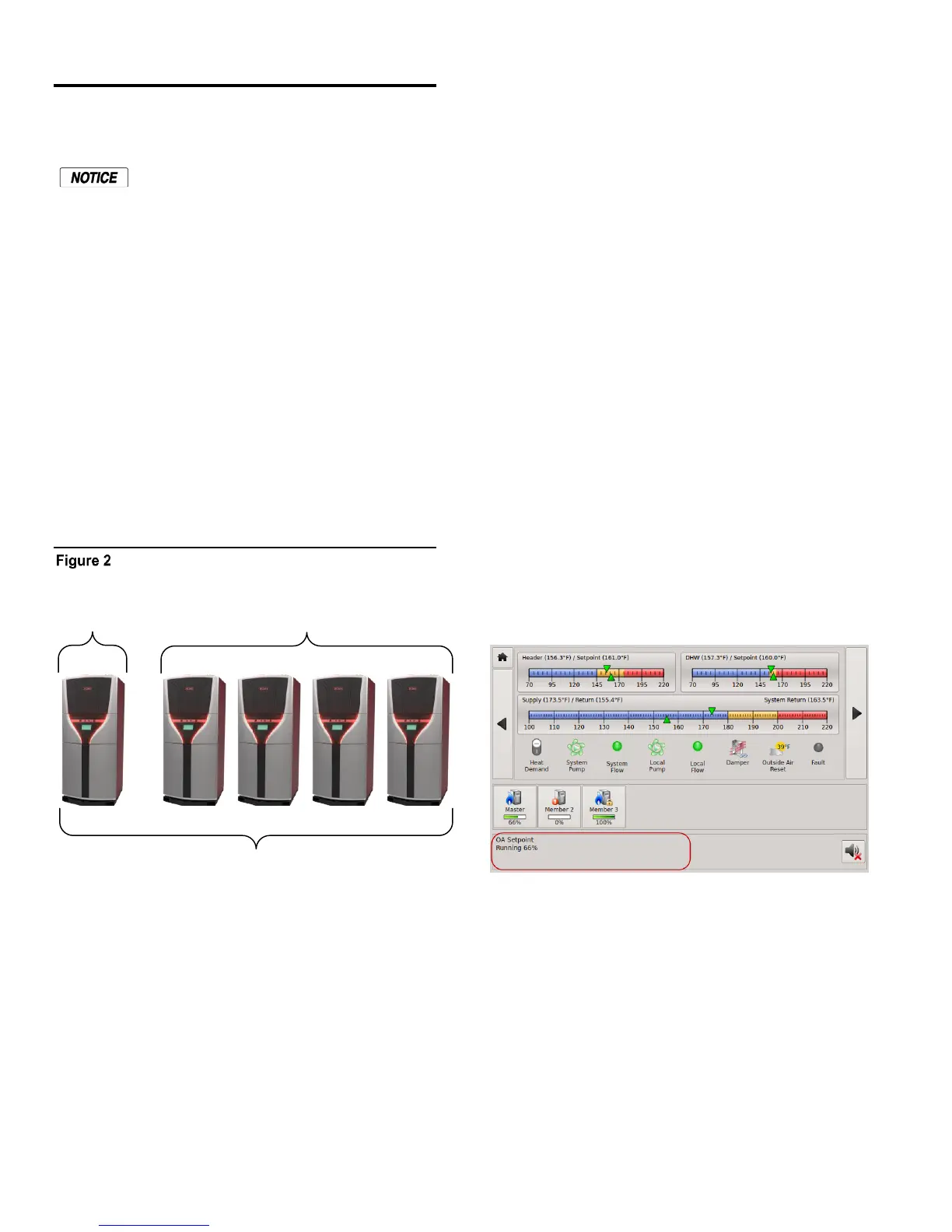

NOTE: Runtime messages are displayed in the lower left

corner of the Home Screen. See Section Messages for

descriptions.

1. The system pump relay is enabled and the H-Net

control displays “Waiting for Flow” until the flow-

switch closes between J11A, 1 & 2 within the

programmed time (10 seconds default).

2. All elements in the interlock string, terminated between

J11A and J11B, must be closed before the sequence is

allowed to continue.

3. If all interlocks are closed, relay K5 is enabled to

command the combustion-air damper open (if used).

The H-Net control displays “Waiting for Damper to

Open” until the damper end switch closes.

4. Relay K6 is enabled energizing the local pump (if

used). The H-Net control commences its Waiting for

1 to 16 Boilers

Member BoilersMaster

Loading...

Loading...