OPTIONAL FEATURES HeatNet Control V3

Page 55

Method 5b can also be used in a hybrid mode on Member

boilers with a thermostat connected to the OR OVR input.

This will enable DHW heating, and be used instead of

having the 10k sensor’s temperature detect when DHW

heating is needed, but will use a selectable sensor instead

to maintain setpoint.

When the OR OVR input sees the thermostat close, the DHW

pump/valve will be engaged and remain energized as long as

the OR OVR input sees that the thermostat is closed. The

DHW setpoint along with the DHW heating band will then be

loaded. A steady temperature will now be maintained using

the HYB SENSOR setting in the DHW menu. This sensor

will control the water temperature at the sensor’s location,

enabling or disabling the boiler as needed until the OR OVR

input sees the thermostat open. Once the thermostat opens,

the DHW pump post purge will begin.

The difference between the settings of method 5a vs. method

5b is the “USE SENSOR” setting. 5a requires that the “USE

SENSOR” setting be set to YES, and the 5b “USE

SENSOR” setting be set to NO. The HYBRID SENSOR

setting must also be set in the 5b mode to the sensor where

temperature needs to be maintained. It must be set to OFF in

the 5a method.

Method 5a USE SENSOR = YES

HYB SENSOR = OFF

Method 5b USE SENSOR = NO

HYB SENSOR = SUPPLY, DHW,

RETURN

Each sensor selection/location has its advantages. Select the:

Supply sensor will limit the temperature/firing rate of the

boiler, but may not be sufficient for continuous demand or

speed in heating the tank. It is already available, so no

additional sensor is needed.

Return sensor will allow the boiler to run its supply

temperature up quickly, but may bounce off of the operating

limit band. This would heat the tank in the shortest time, but

may overheat the tank. It is already available, so no additional

sensor is needed.

DHW sensor will allow the placement anywhere needed to

maintain that locations temperature. This is an additional

sensor that needs to be acquired.

A thermostat can be placed in a tank and connected to the OR

OVR input. (On Member boilers only, The Master uses OR

OVR already with DHW METHOD 4), When the thermostat

contact closes across the input OR OVR (J12A .7 & .8) on a

Member boiler, the control will sense this closure and

disconnect itself from HeatNet.

DHW METHOD 6: DHW using Direct

Control

If the control’s SETTINGS: 4-20 mA input is set to

PRIORITY = HIGH the 4-20 mA signal, once brought above

the 4-20 mA starting current can be used to override any other

Heat Demand and direct modulate the boiler.

This can be set in menu: ADVANCED SETUP: 4-20 mA

INPUT. It allows a member boiler to be taken offline and

directly modulated by an external control.

If the Master is using it for heating and the ADVANCED

SETUP: 4-20 mA is set to PRIORITY= HIGH, an external

control can now output a 4-20 mA signal which will take over

the boiler’s fire rate and override all other heating demand

inputs. The external control would also need to open any

valves or turn on pumps. This is typically used for DHW

Control.

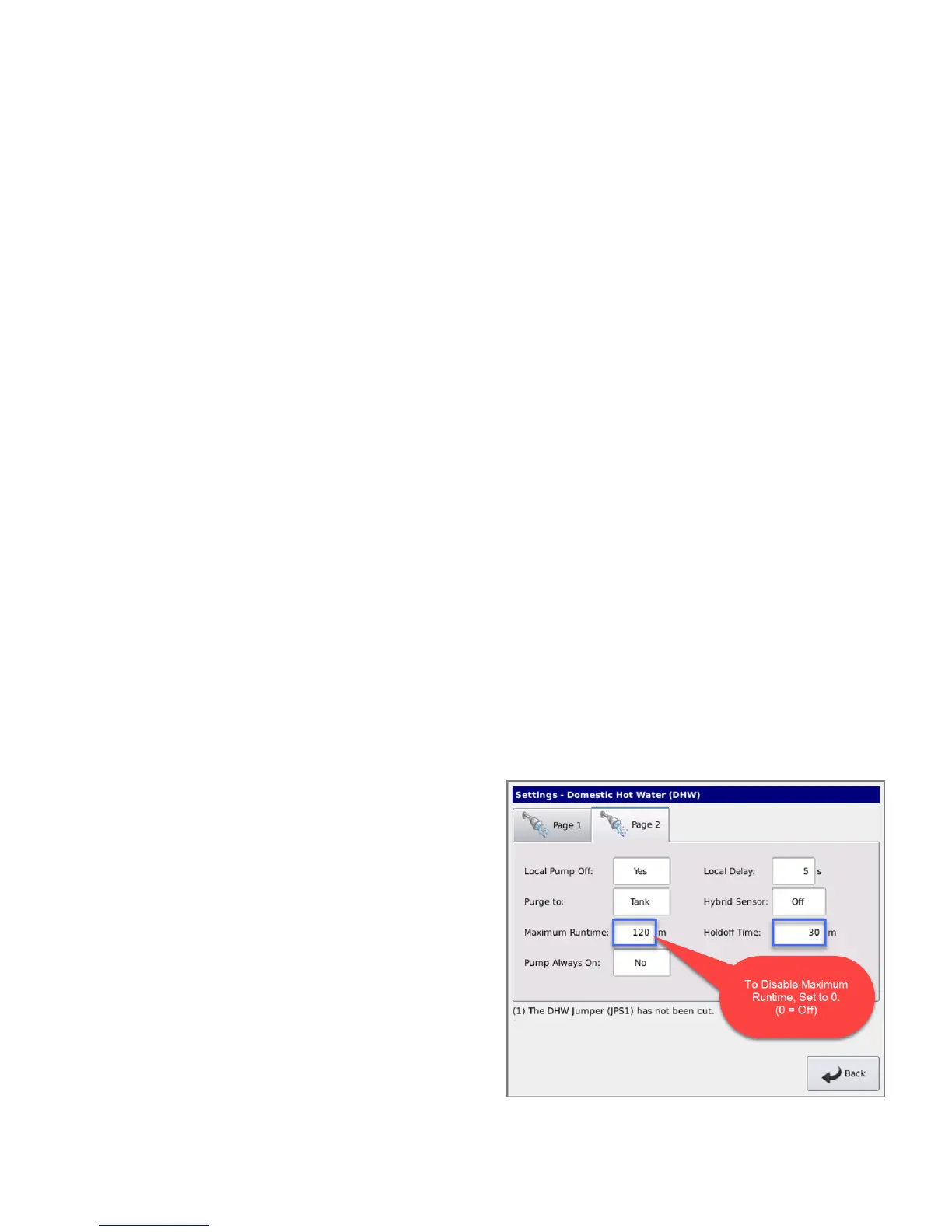

DHW Maximum Runtime

When a Combination system has a call for DHW heat and

services it for a time that is longer then designed, the DHW

may need to be locked out or held off for a predetermined

amount of time (retry).

Two settings are provided to control this situation: the

Maximum Runtime, and the Holdoff Time. The Maximum

Runtime is set to allow the DHW call to occur for the design

time of the system. If for some reason this time is exceeded,

the Holdoff Time setting goes into effect. The Holdoff time

can be set to a Lockout (the OR OVR input needs to toggle or

a power cycle to clear the Lockout), or a fixed amount of

boiler off time. If the fixed amount of Holdoff time is

selected, the DHW functionality will be cycled between the

boilers running for the Maximum Runtime, and stopped for

the duration of the Holdoff Time.

Loading...

Loading...