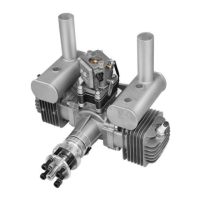

The RCGF 70CC-Twin is a two-stroke, piston-valve type gasoline engine designed specifically for model airplanes. This engine is equipped with a DC-CDI (Computer Controlled auto advance) electronic ignition system, ensuring reliable starting and consistent performance. It operates on a mixture of gasoline and two-cycle oil, with a recommended mix ratio for optimal engine life and performance. The engine is designed to be air-cooled, a common and effective method for dissipating heat in model aircraft applications.

Usage Features:

To ensure safe and effective operation, several key features and procedures must be followed. The engine requires a power supply for its ignition system, typically a 4.8-8.4V battery. For optimal performance, it is recommended to use fresh or recently purchased 93 octane unleaded gasoline, mixed with a high-quality two-cycle engine oil at a 30:1 ratio. The engine's speed range allows for both low idle speeds and high RPMs, making it versatile for various flight conditions.

Propeller selection is crucial, and suggested propellers include specific sizes like 22x10, 23x8, 23x10, and 24x8. For the break-in period, a 23x10 propeller is recommended to ensure proper seating of components. The engine uses an NGK CM6 type spark plug.

Installation of the engine involves securing it to a sturdy firewall, at least 9.5mm (3/8") thick, made of 5-ply plywood. The firewall must be securely glued and reinforced. The engine is mounted using blind nuts and SHCS bolts with lock washers and standoffs. Threadlocking compound should be used on all screws.

The fuel system requires a gasoline-approved fuel tank and lines, with a gasoline-approved stopper. A two-line or three-line fuel system can be set up, with one line going to the carburetor and others for venting and filling. Non-metallic linkages are recommended for the throttle and choke servos, which should be installed at least 12 inches (305mm) away from the engine to prevent radio interference. High-torque metal gear servos are suggested for throttle control.

The electronic ignition module should be securely installed in the airplane's forward area, with foam rubber and Velcro recommended for vibration dampening. All electronic radio devices should be kept at least 12 inches (305mm) away from the engine. An ignition system kill switch is mandatory for safety.

Propeller installation involves drilling the propeller to fit the hub. A drill guide is ideal, but a manual method is provided. The propeller's center hole should be pre-drilled, and then outer holes marked and drilled. The engine must be set at the top of the compression stroke, and the propeller placed at the one o'clock position on the crankshaft before marking the outer holes. Threadlocker should be used when mounting the propeller.

Starting procedures include both manual and electric starter methods. For manual starting, a thick glove or heavy-duty starter stick is essential. The ignition is switched ON, the choke closed, and the throttle slightly open. The propeller is flipped briskly counter-clockwise until a popping sound indicates firing. Then, the choke is opened, and the propeller flipped again to start the engine. For electric starter starting, a 12-24V electric starter is recommended, along with a good quality, lightweight aluminum spinner. The process is similar, using the electric starter to turn the engine until it fires. During break-in, it's recommended to run the engine without the cowling.

The engine's carburetor comes factory preset, but minor adjustments may be needed based on elevation. The Idle Adjustment Screw controls idle speed, while the Low-speed and High-speed Needles adjust the fuel/air mixture at low and high speeds, respectively. These adjustments are crucial for optimum output and smooth acceleration/deceleration. The ignition timing is preset but can be adjusted by loosening the ignition sensor screws and sliding the sensor. Advancing the timing can increase performance but may also raise engine temperatures and cause premature wear.

Maintenance Features:

Regular maintenance is key to the longevity and performance of the RCGF 70CC-Twin engine. The manual emphasizes the importance of keeping the engine surface clean to ensure proper heat dissipation and adequate cooling/ventilation around the cylinder.

Periodically, the fuel filter in the carburetor should be cleaned. This involves removing the Phillips head screw that secures the carburetor filter cover and the carburetor filter gasket. Only carburetor cleaner should be used to clean the opening around the filter. Failure to clean the fuel filter can lead to miss-calibration of the needle adjustments and reduced engine performance.

Before transporting the model, all fuel should be removed from the fuel tank and lines. If the engine is not to be used for more than a month, the fuel tank should be drained, and any fuel removed from the carburetor by running the engine at idle until it quits. This prevents damage to the diaphragm valve and clogging of passages within the carburetor.

The engine package includes essential spare parts for maintenance and initial setup, such as the electronic CDI ignition, muffler, spark plug, gaskets, bolts, throttle arm extension, and the manual itself. The engine has a two-year limited warranty through the RCGF service center, requiring the retention of the purchase receipt as proof.