24

PID Adjustments

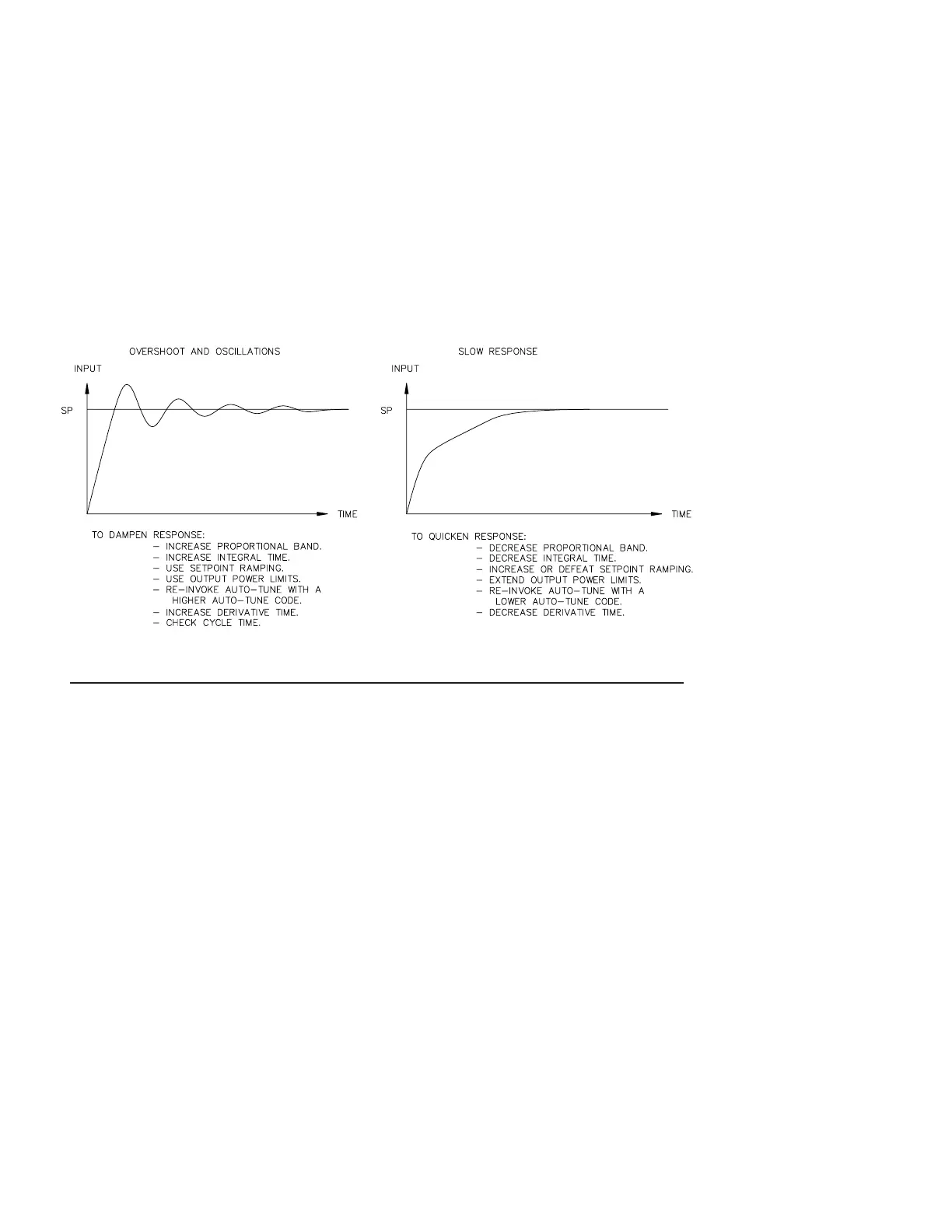

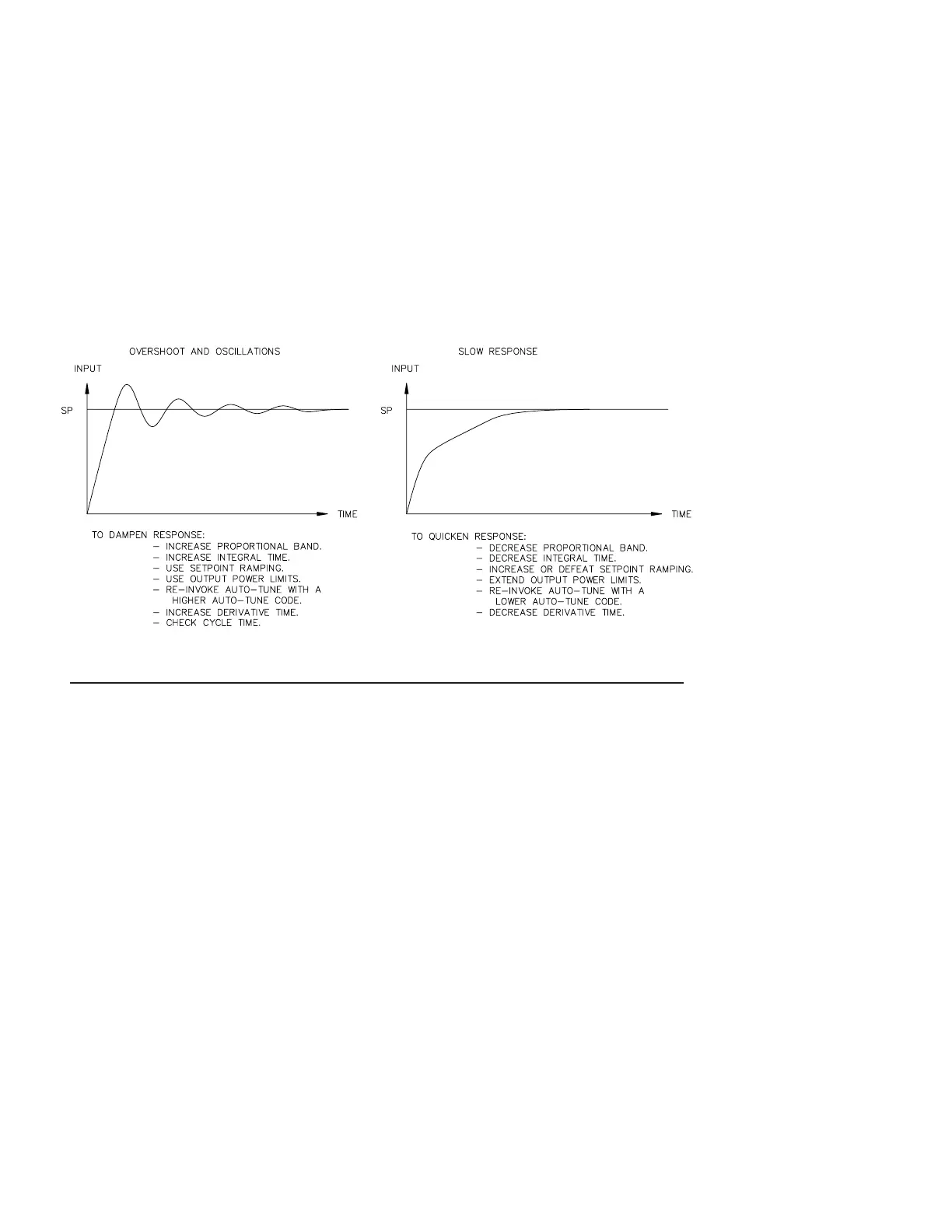

In some applications, it may be necessary to fine tune the

Auto-Tune calculated PID parameters. To do this, a chart

recorder or data logging device is needed to provide a visual

means of analyzing the process. Compare the actual process

response to the PID response figures with a step change to the

process. Make changes to the PID parameters in no more than

20% increments from the starting value and allow the process

sufficient time to stabilize before evaluating the effects of the new

parameter settings.

In some unusual cases, the Auto-Tune function may not yield

acceptable control results or induced oscillations may cause

system problems. In these applications, Manual Tuning is an

alternative.

PROCESS RESPONSE EXTREMES

MANUAL TUNING

A chart recorder or data logging device is necessary to

measure the time between process cycles. This procedure is an

alternative to the controller’s Auto-Tune function. It will not

provide acceptable results if system problems exist.

1. Set the Proportional Band (

&+;&) to 10.0% for temperature

models (T16) and 100.0% for process models (P16).

2. Set both the Integral Time (

12,,) and Derivative Time (-'+,) to

0 seconds.

3. Set the Output Dampening Time (

"&-&) in Output Module 8."&

to 0 seconds.

4. Set the Output Cycle Time [CYCt] in Output Module

8."& to no

higher than one-tenth of the process time constant (when

applicable).

5. Place the controller in Manual

%)'+ Control Mode ,+2/ in the

Hidden Loop and adjust the % Power to drive the process

value to the Setpoint value. Allow the process to stabilize after

setting the % Power. Note:

,+2/ must be set to *E-' in

Parameter Lockouts Module

3.#4.

6. Place the controller in Automatic (

:>,;) Control Mode ,+2/ in

the Hidden Loop. If the process will not stabilize and starts to

oscillate, set the Proportional Band two times higher and go

back to Step 5.

7. If the process is stable, decrease Proportional Band setting by

two times and change the Setpoint value a small amount to

excite the process. Continue with this step until the process

oscillates in a continuous nature.

8. Fix the Proportional Band to three times the setting that

caused the oscillation in Step 7.

9. Set the Integral Time to two times the period of the oscillation.

10. Set the Derivative Time to 1/8 (0.125) of the Integral Time.

11. Set the Output Dampening Time to 1/40 (0.025) the period of

the oscillation.

Loading...

Loading...