10

5 INSTALLATION

5.8 Cable sizing

Below is a table outlining the required cable size for a given cable install length. Always choose a wire

diameter equal to or greater than what is specified below.

Part Number

Cable Install

Length

Recommended Wire

Size (mm²)

Nearest Equivalent

B&S, BAE, AWG

DPS1225/

DPS2410

1–5m 3–16' 7.71 8

5–9m 16–30' 13.56 6

DPS1240/

DPS2420

1–5m 3–16' 13.56 6

5–9m 16–30' 20.28 4

5.9 Wiring

The heavy gauge wires on the DPS1225, DPS1240, DPS2410 and DPS2420 unit carry peak currents of up

to 40A and it is important to make a good, low resistance, electrical connection that will not degrade over

time. Failure to make a good, reliable contact may result in breakdown of the wire insulation and cause

a short circuit, or worst case a fire. We recommend that this activity be undertaken by an appropriately

trained person.

REDARC recommends using a soldered butt splice crimp connection that is covered with heatshrink. Do

not use standard red/ blue/yellow blade connections as they are not rated for either the current required

or gauge of wire supplied on the unit.

Crimping provides good mechanical connection; soldering provides a long lasting electrical connection

and forming of the heatshrink will reduce the risk of shorting/contact with your vehicle chassis.

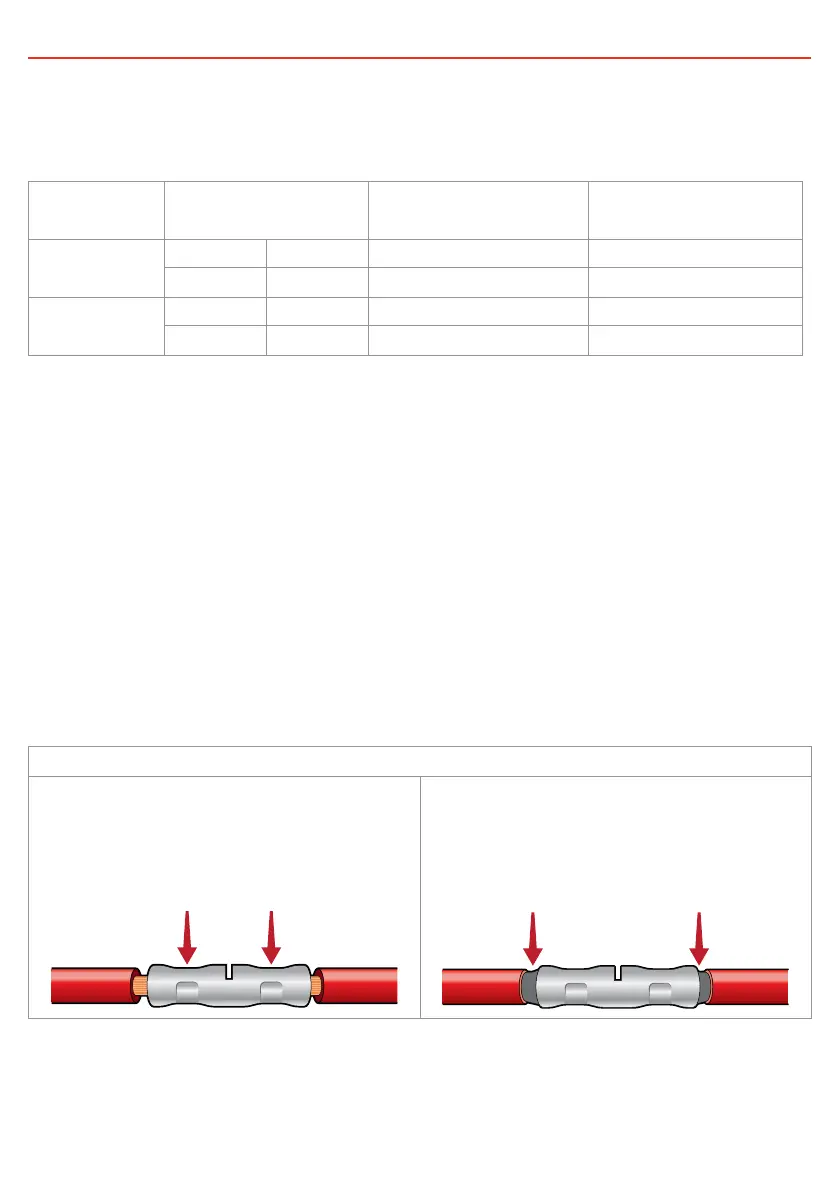

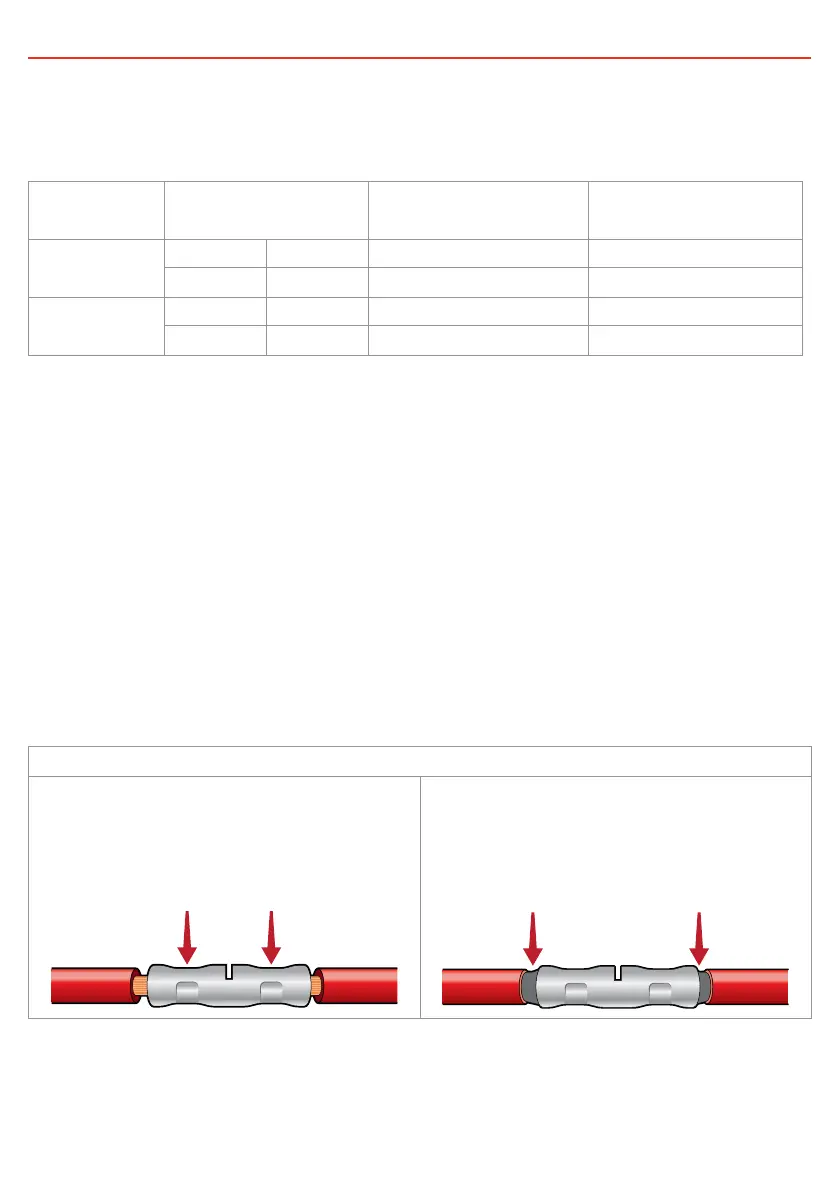

Figure 4: Ensure Good Wiring Connection

Crimp both wires to the butt splice using

single-indent type crimpers. Fold the cable over

before inserting into the butt-splice as required.

Single-indent crimpers should also be used

on any lugs used.

Solder the wires to the butt splice. Ensure that a

good connection is made. Keep heatshrink away

until after soldering is complete and has cooled.

Loading...

Loading...