59

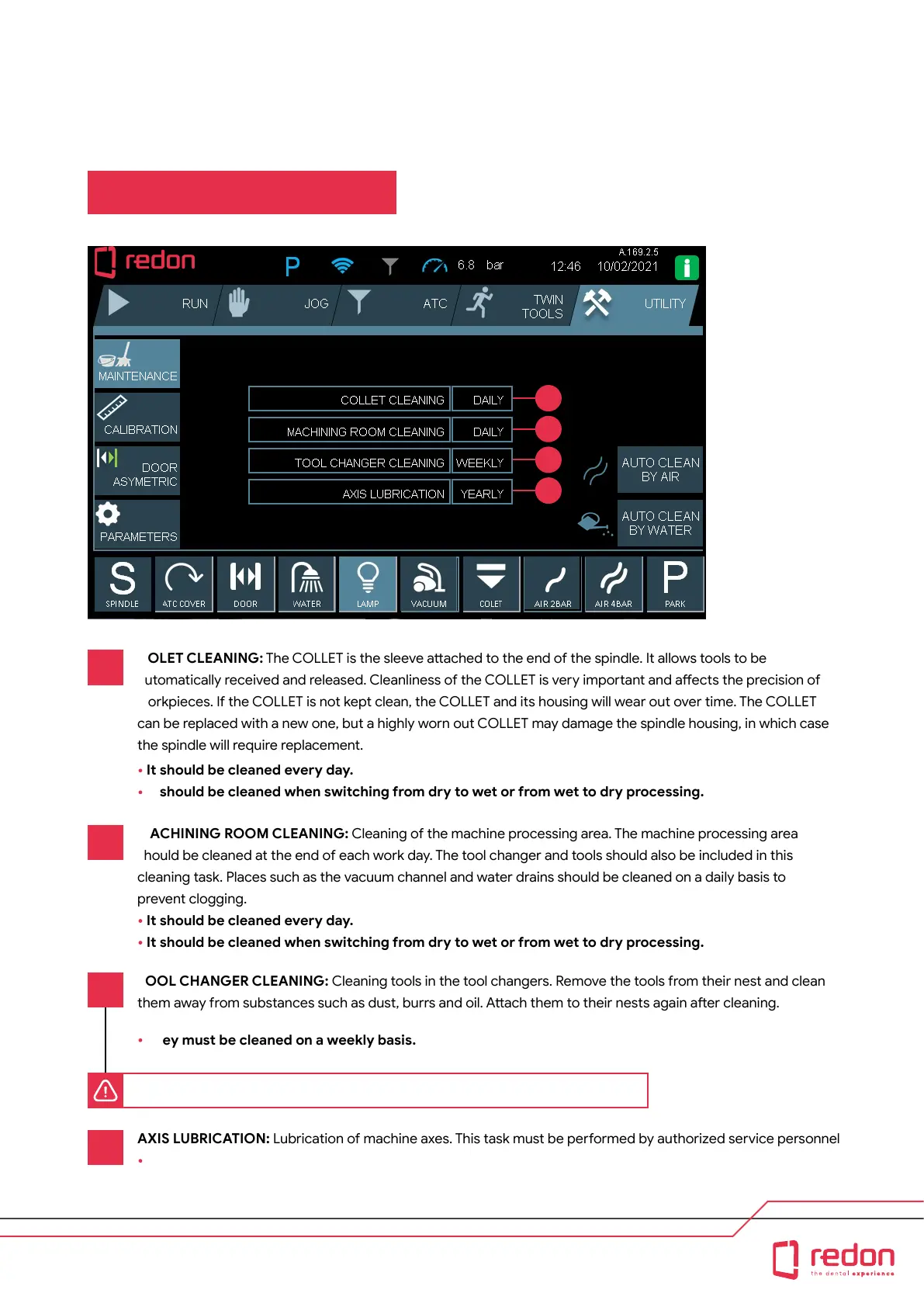

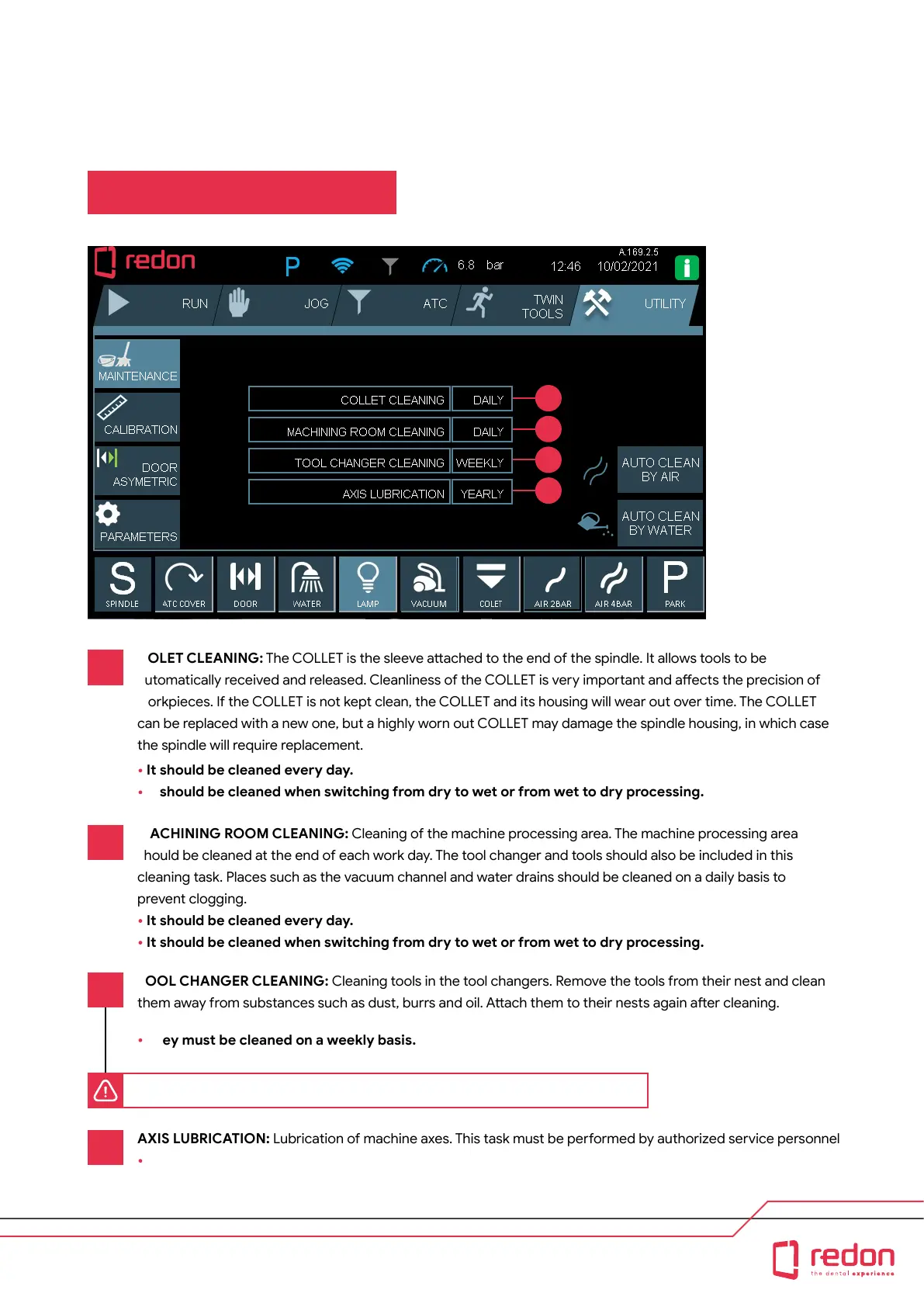

USER INTERFACE / UTILITY

UTILITY / MAINTENANCE

COLET CLEANING: The COLLET is the sleeve aached to the end of the spindle. It allows tools to be

automatically received and released. Cleanliness of the COLLET is very impoant and aects the precision of

workpieces. If the COLLET is not kept clean, the COLLET and its housing will wear out over time. The COLLET

can be replaced with a new one, but a highly worn out COLLET may damage the spindle housing, in which case

the spindle will require replacement.

• It should be cleaned every day.

• It should be cleaned when switching from dry to wet or from wet to dry processing.

When you select MAINTENANCE under UTILITY, a list of daily,

weekly and yearly maintenance activities is shown.

MACHINING ROOM CLEANING: Cleaning of the machine processing area. The machine processing area

should be cleaned at the end of each work day. The tool changer and tools should also be included in this

cleaning task. Places such as the vacuum channel and water drains should be cleaned on a daily basis to

prevent clogging.

• It should be cleaned every day.

• It should be cleaned when switching from dry to wet or from wet to dry processing.

TOOL CHANGER CLEANING: Cleaning tools in the tool changers. Remove the tools from their nest and clean

them away from substances such as dust, burrs and oil. Aach them to their nests again aer cleaning.

• They must be cleaned on a weekly basis.

AXIS LUBRICATION: Lubrication of machine axes. This task must be peormed by authorized service personnel.

• It must be peormed every year.

1

2

3

4

CAUTION! Tools must be aached to the same nests from which they were originally removed.

1

2

4

3

Loading...

Loading...