07 System protection

7.1

General

• Prior to any installation, ensure all components

being used are REHAU EDGE

TM

components only

•

Do not use dirty or damaged system components, pipes,

fittings, compression sleeves or seals.

• Make sure that the connection components are free

of inadmissible stress during assembly and when

in operation. Make sure that the piping has suicient

scope of movement (e.g. from deflection legs).

• Protect the system against damage (e.g during

the construction phase and when installed in areas

with vehicles and machines)

Installation temperature

• Minimum installation temperature is -5ºC

• Maximum installation temperature is +50ºC

7.2

Protection against corrosion and damage

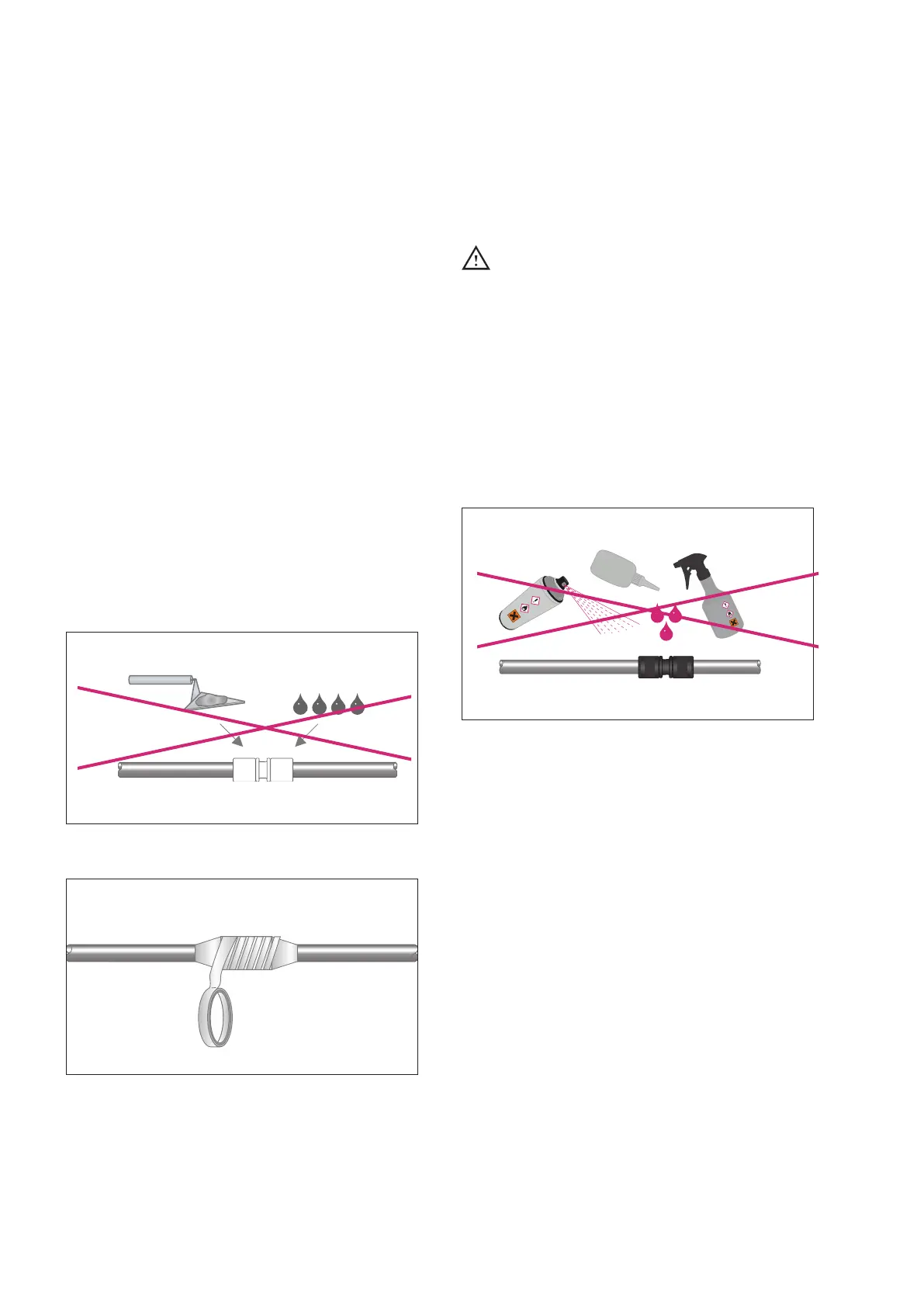

• Screed, cement, mortar, plaster, bonding agents

and other materials and substances may

cause corrosion. Where a contact with such

substances is foreseeable, protect fittings

and compression sleeves from contact, e.g

by wrapping with RAUTITAN protective

tape, silicone tape or another suitable tape.

Petrolatum tapes, or tapes containing solvents

are NOT suitable.

• Do not install pipes and fittings, pipes

and compression sleeves in wet areas

(e.g. green houses, indoor pools, or conditions

where water or condensation on the surfaces

must be expected on a regular basis)

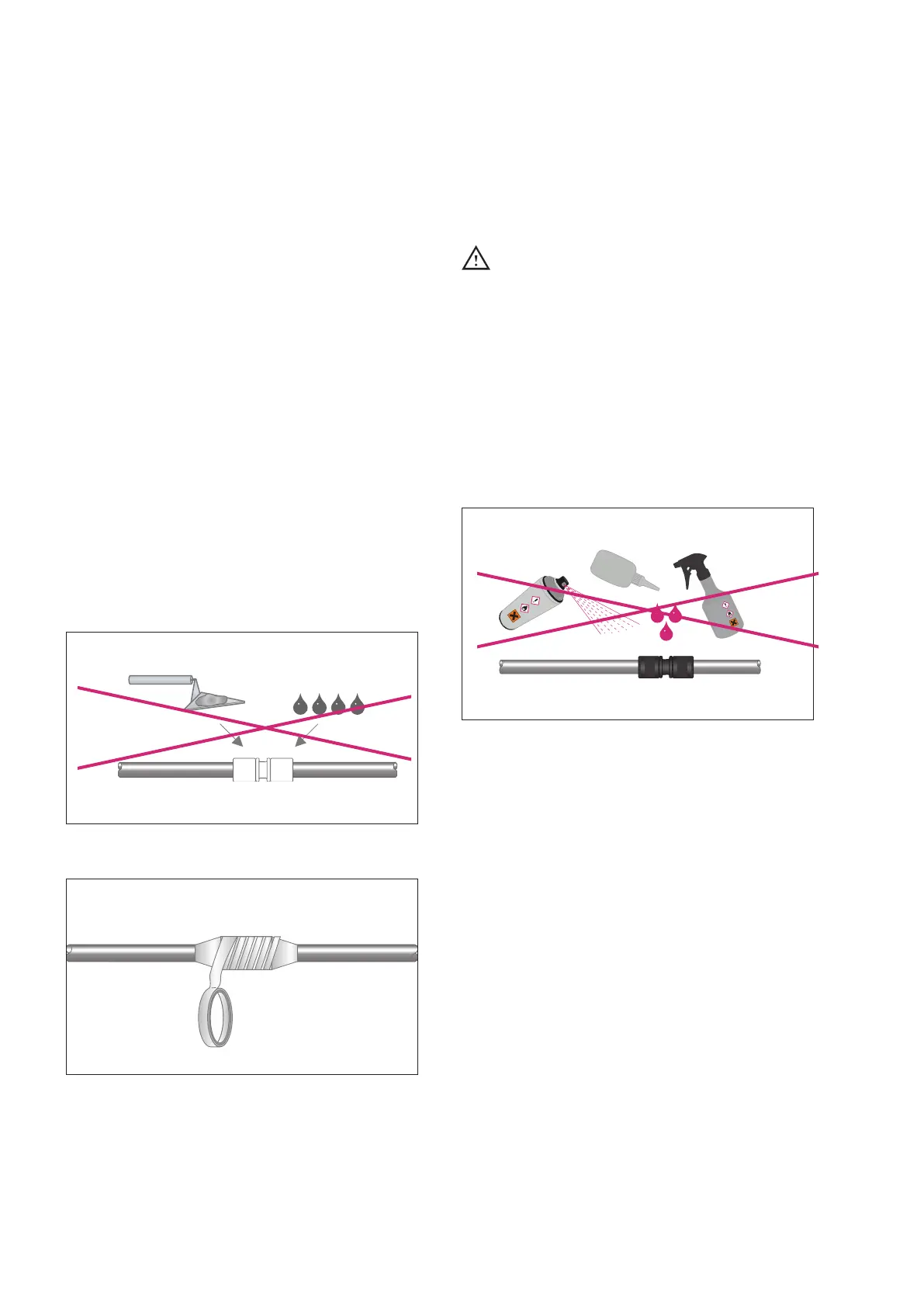

Fig.

7

-2 Avoid contact with solvents and oils including paints,

lacquer, liquid thread sealant and tapping oil.

EDGE

TM

polymer fittings

• EDGE

TM

polymer fittings are solvent resistant and

have excellent resistance against most aliphatic and

aromatic hydrocarbons and Chlorine.

Solvent resistant means that EDGE

TM

polymer fittings

are not susceptible to environmental stress cracking

when in contact with solvents found in glues,

primers and thread sealants commonly used on building

sites. Only use leak detection agents (e.g. foaming

agents), sealants, thread sealants, cleaning agents,

building foams, insulation, protective tape, adhesive

tape and flux, which were approved by the respective

manufacturer for PVDF.

• When using the connection components, check the

compatibility of materials for the corresponding area

of application.

• Contact with basic environments with pH≥12 is

not permitted.

Fig. 7-1 Protect connection components against corrosion

and damage

Loading...

Loading...