5.1 EDGE

TM

Installation Steps – General overview

• Permanently sealed joint

• Without O-ring (self-sealing pipe material)

• Easy visual inspection

• Can be immediately pressurized

• Pipe doesn’t need to be calibrated or deburred

•

Robust jointing technology, highly suitable for

construction sites

• Connection leaks when not compressed

• Compression can be carried out with water inside,

but must be pressure-less

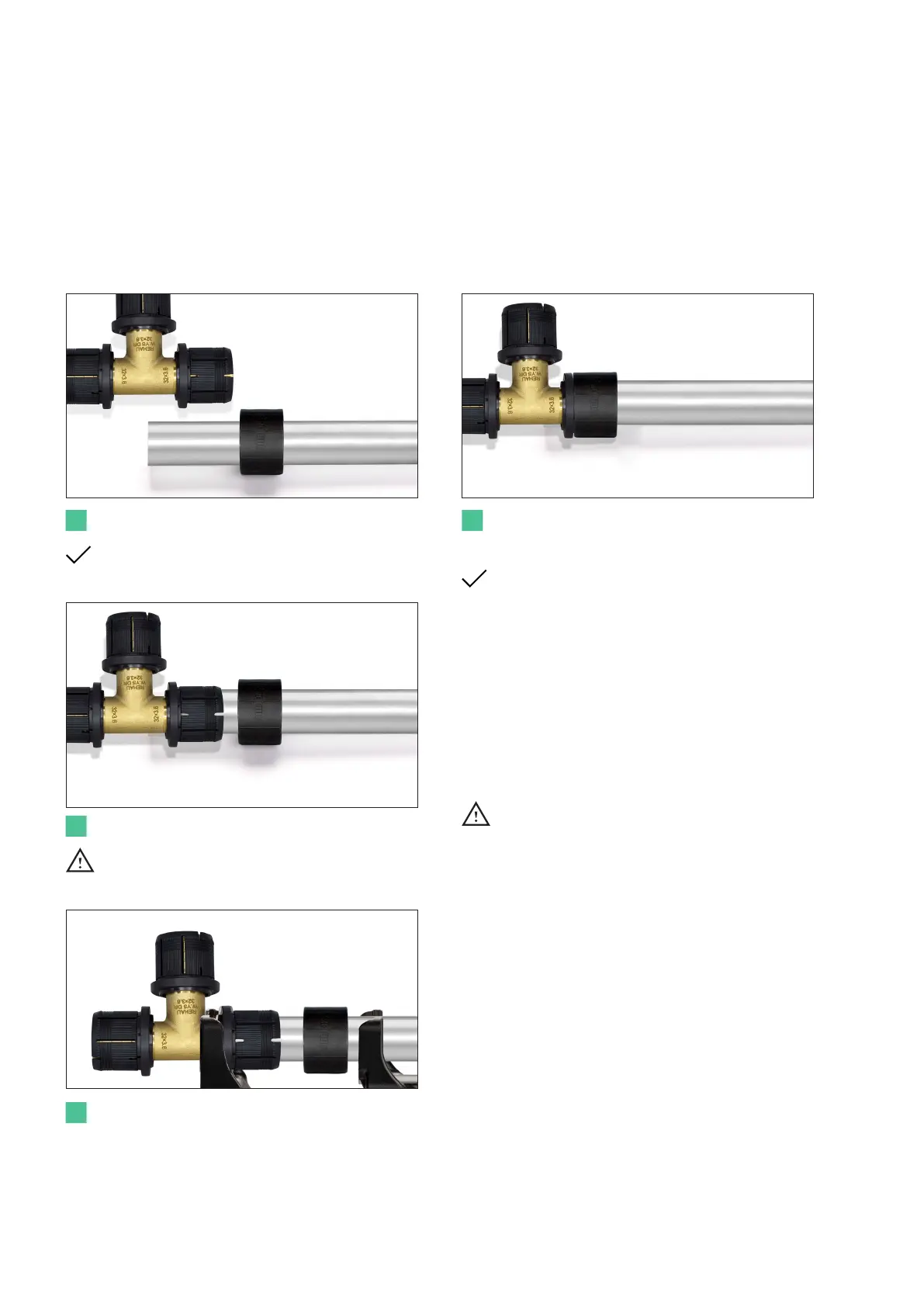

2 Insert into the fitting and push fully home

Check the inspection window on the inner sleeve

to ensure the pipe is visible inside.

EDGE

TM

compression sleeves can be fitted from

both sides

3

Make the compression

Only make connections using RAUTOOL.

Please observe the Technical Information and

the corresponding operating instructions and

instruction leaflets for information on handling the

tools and making connections. Do not use dirty

or damaged connection components or tools. The

range of connection components can be found in

the latest product book.

Installation temperature

• Minimum installation temperature is -5 °C.

• Maximum installation temperature is +50 °C.

05 Making the EDGE

TM

connection

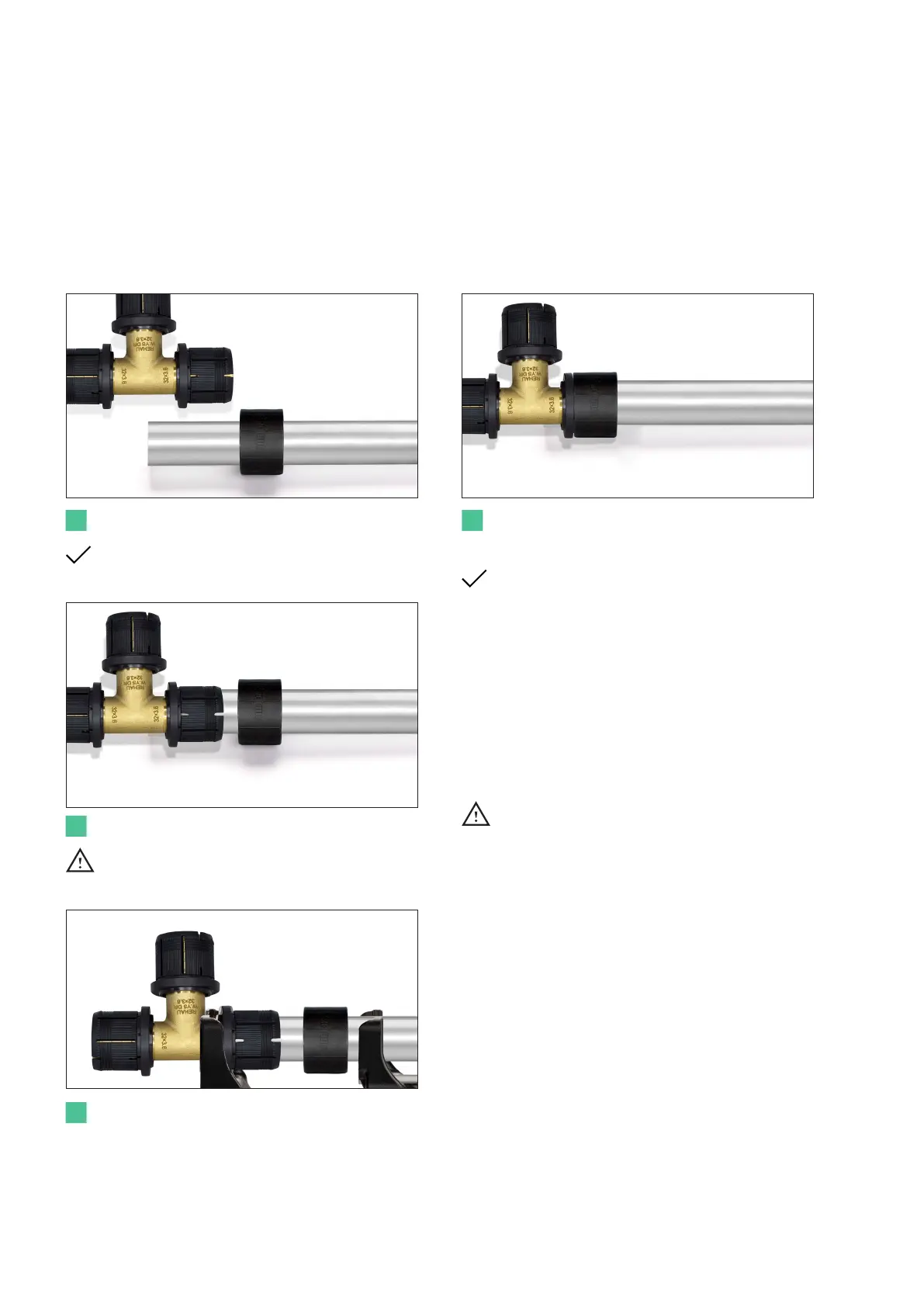

1 Push the sleeve over the pipe 4 Fully compressed joint

Loading...

Loading...