5.2 Cutting the pipe

5.3 Sliding the EDGE

TM

sleeve onto the pipe

Fig. 5-2 Sliding EDGE

TM

sleeves onto the pipe

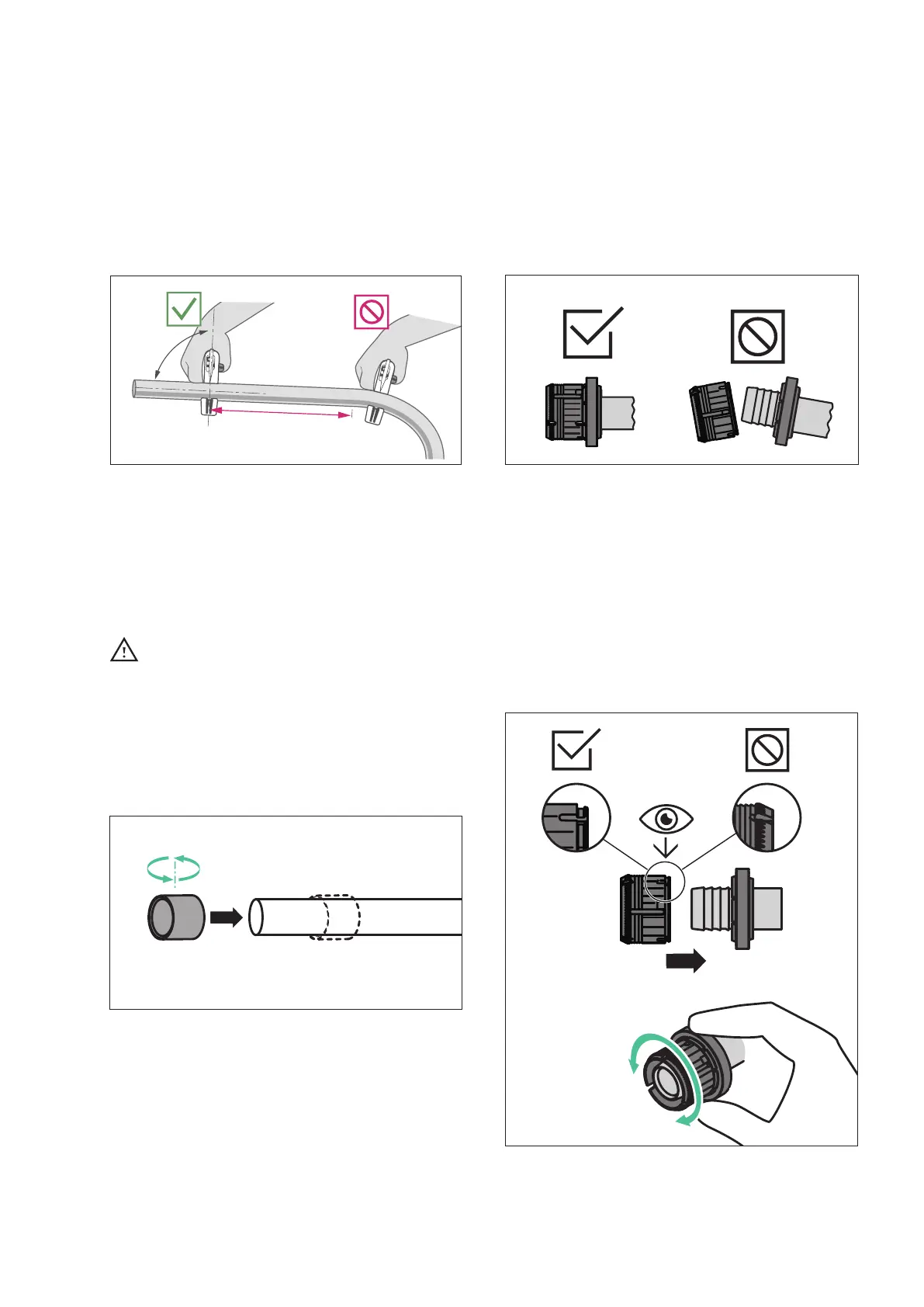

EDGE

TM

Sleeves are reversible and can be put onto the pipe

in either direction.

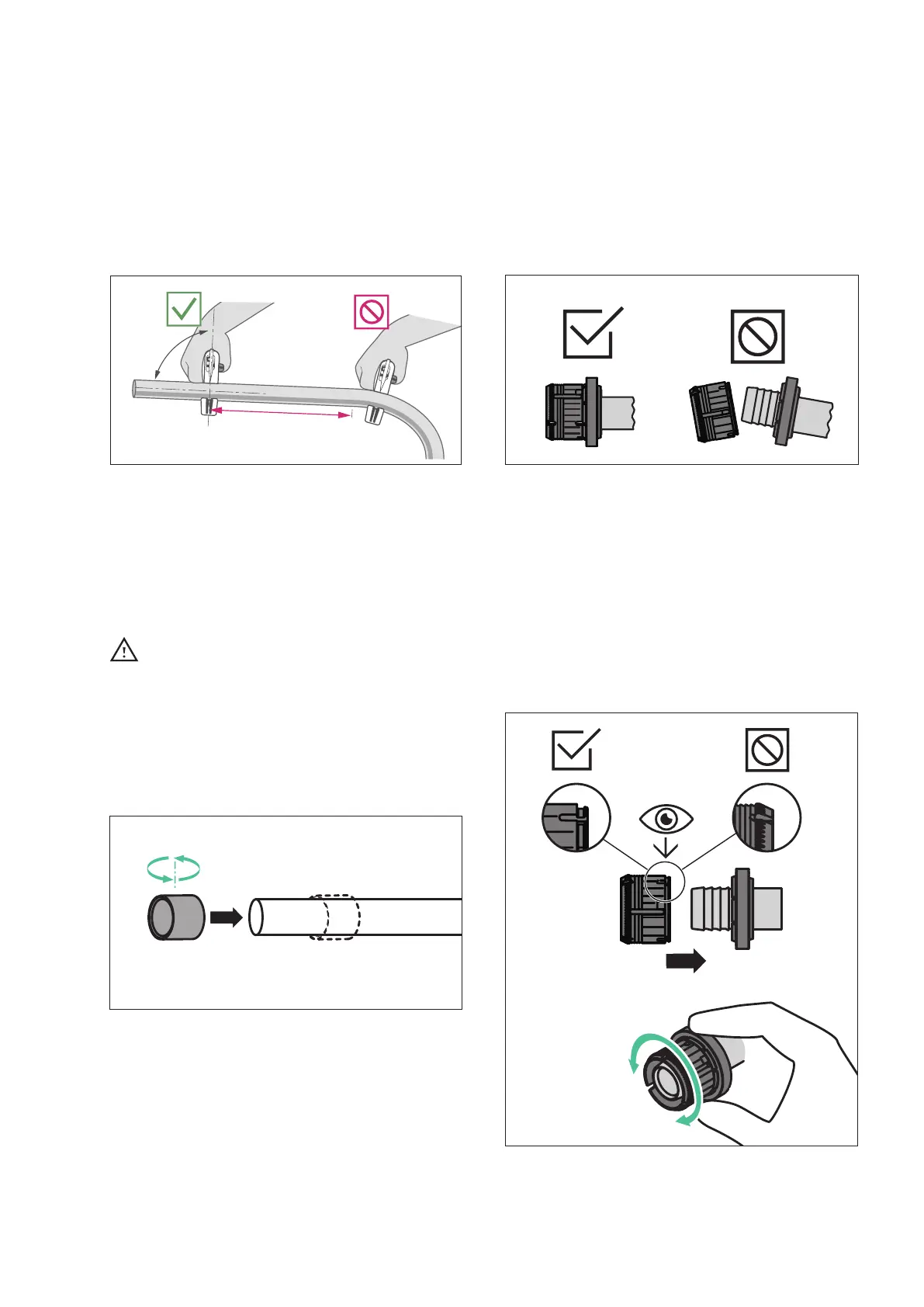

Fig. 5-1 Cut the pipe at 90° and without burrs

1. Prior to cutting the pipe ensure the cut length accounts

for the insertion depth of the pipe into the EDGE

TM

Fitting (Approximately 1 sleeve length).

2. Select the appropriate pipe cutter (refer to Tab 4-1).

3. Cut the pipe at 90° and without burrs.

• Check the blade of the pipe cutters regularly for

damage and replace the blade or the cutters as

necessary.

• If the pipe was cut improperly, re-cut the pipe to

ensure a square and burr-free cut.

Check that the inner sleeve is in the correct position. If

necessary, re-insert the loose inner sleeve onto the clip.

•

Note the direction of insertion: Inner sleeve groove facing

the clip, chamfer on the other side.

• Push the inner sleeve back onto the clip by hand.

• Check the correct position of the inner sleeve: Hold the

clip and turn the inner sleeve at the same time. The inner

sleeve shall be easy to turn and shall be fully assembled

before making the joint.

5.4 Checking the Fittings

Loading...

Loading...