Page 23

Section D

Contents

Description

Routine maintenance

Operation 1 Toe-in adjustment, front wheel alignment

Operation 2 Camber adjustment

Operation 3 Castor angle adjustment

Operation 4 Steering wheel - removal and replacement

Operation 5 Steering lock/ignition switch - removal and

replacement

Operation 6 Steering column - removal and replacement

Operation 7 Steering rack - removal and replacement

Operation 8 Steering rack damper adjustment

Operation 9 Steering rack pinion preload adjustment

Operation 10 Steering gear overhaul, including inner ball joint

removal and bellows removal

Track rod inner ball joint renewal

Steering gear overhaul

Replacing steering rack gaiters

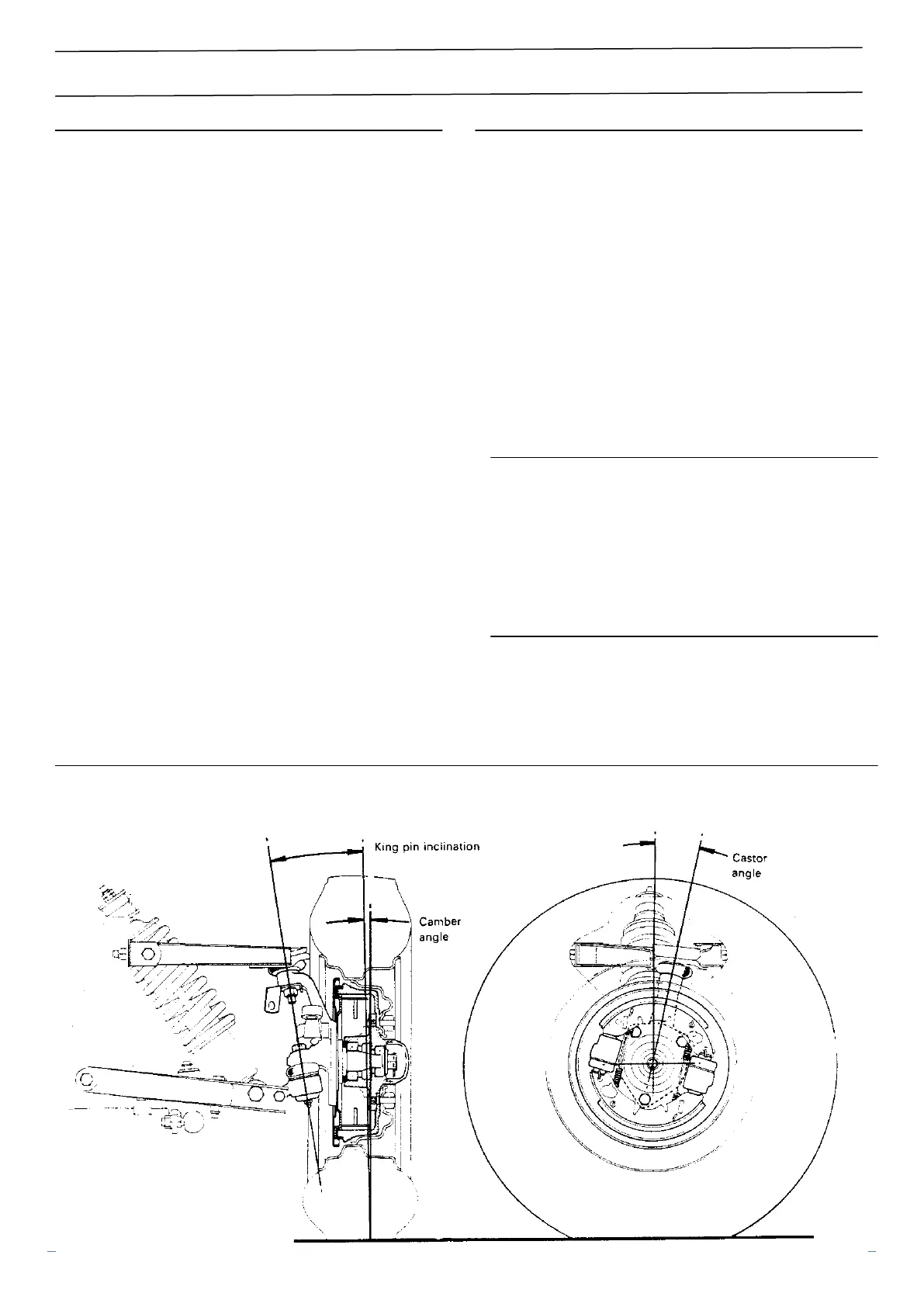

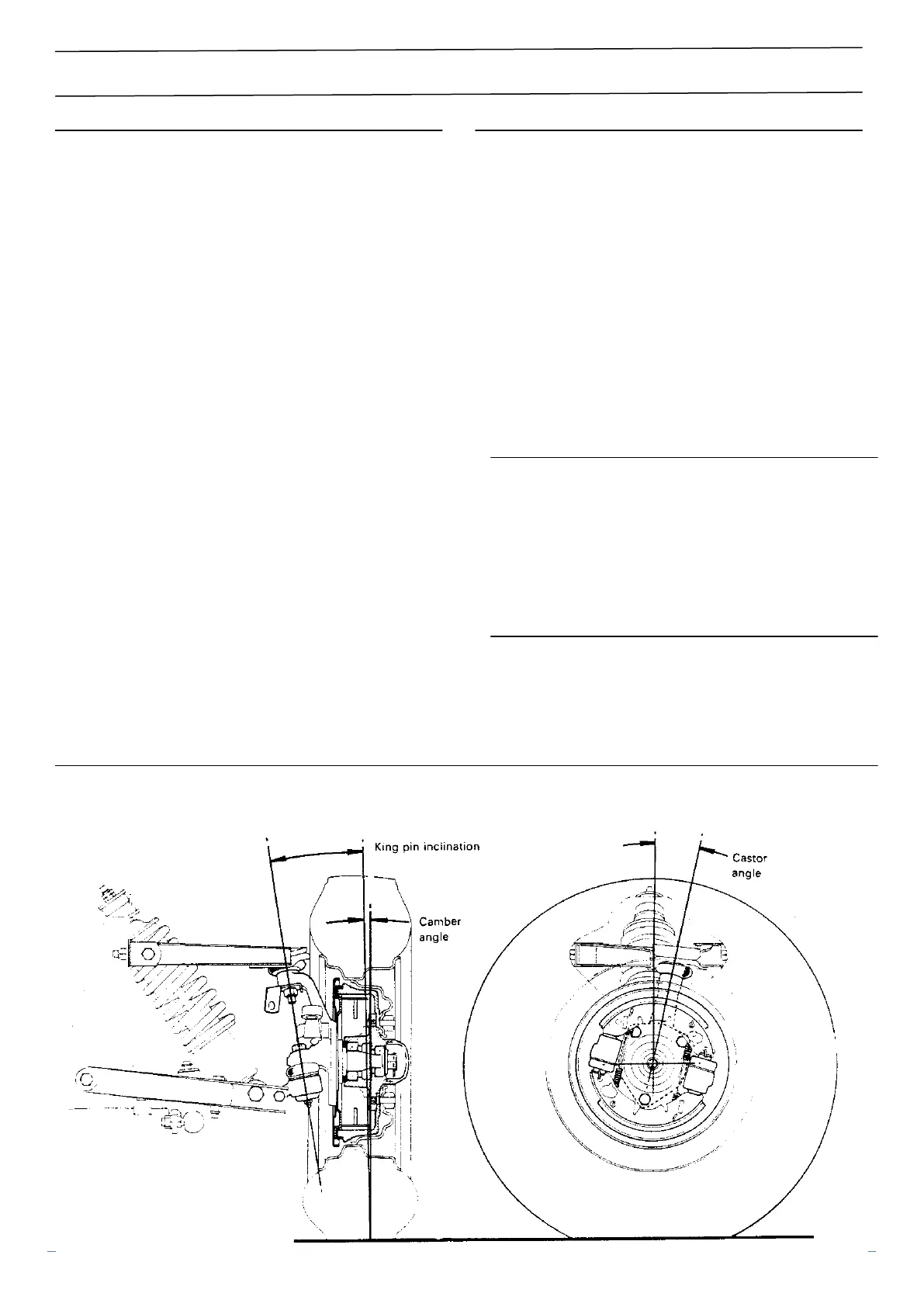

Figure 1 Castor, camber and king pin inclination

Steering

Description

The rack and pinion steering gear is mounted in rubber insulators

attached to the front cross member.

Movement of the steering wheel is transmitted by the steering shaft

through a flexible coupling to the helically toothed pinion. Rotation of

the pinion causes the rack to move laterally and the track rods,

attached to the ends of the rack, transmit this movement to the

steering arms and thus the road wheels to turn.

The track rod inner ball joints, attached to the rack, are protected by

convoluted rubber gaiters and the track rod outer ball joints, attached

to the steering arms, are protected by conventional rubber seals.

The unit contains 0.189 litre (½ pint) SAE 90 Hypoid gear oil, which is

put in during manufacture and normally no further lubrication is

required. On no account should the steering unit be completely filled

with oil. This will result in a pressure build-up which could burst or

blow off the gaiters.

Rack and pinion adjustments

The design and construction of the steering gear provides for two

adjustments:

(a) Rack damper adjustment

(b) Pinion bearing preload adjustment

Both these adjustments are obtained by varying the thickness of a

shim pack under a cover plate. It is necessary to remove the assembly

to carry out any adjustment.

Castor, camber and toe-in adjustments

The track rod ends are adjustable for length to permit toe-in setting.

The castor, camber and king pin inclination angles are set during

production, but provision is made for adjustment of castor and

camber angles by the addition or deletion of shims behind the upper

wishbone mountings brackets.

Loading...

Loading...