Page 59

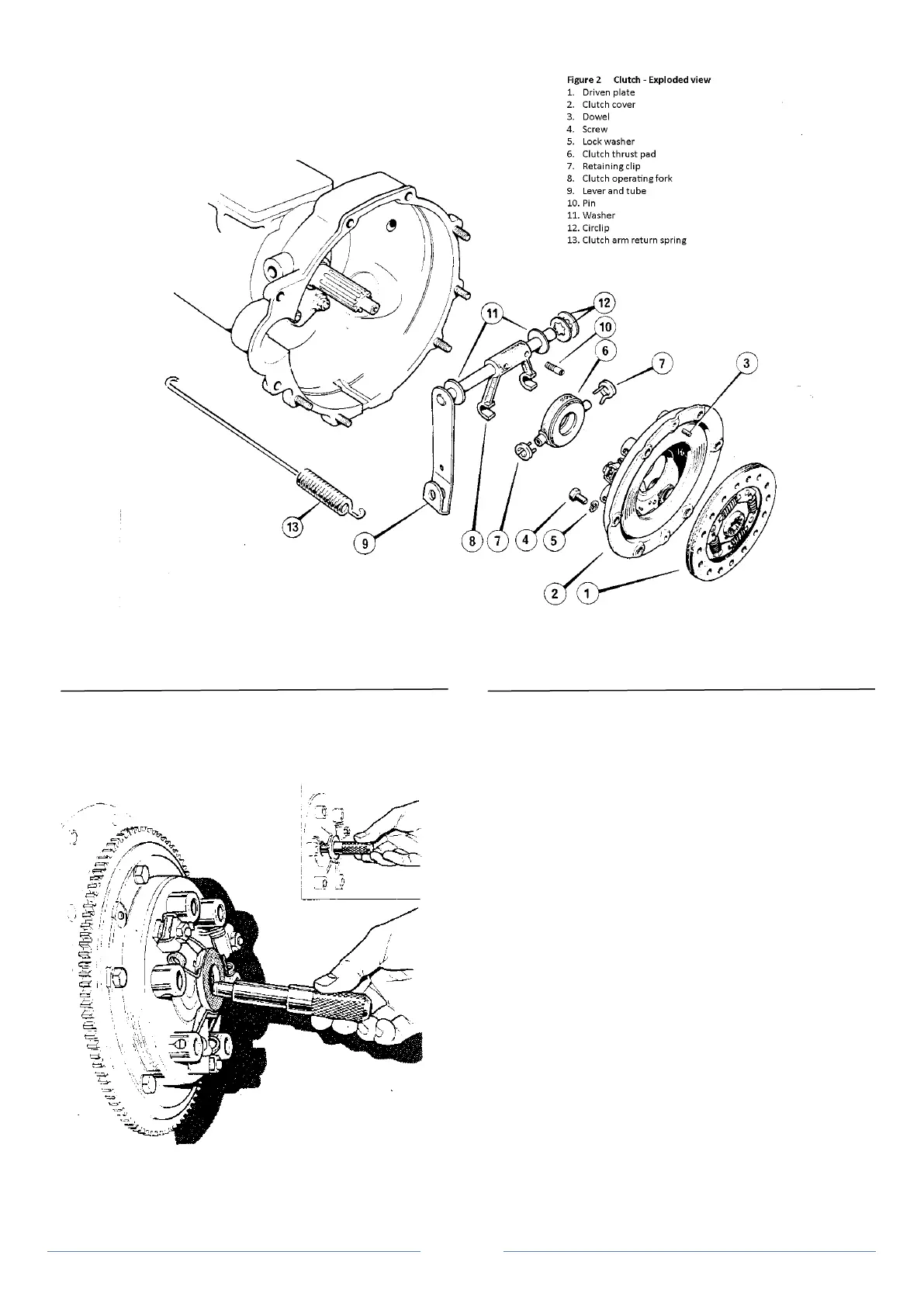

Figure 3 Centralising the clutch

Tap the pressure plate assembly with a hide mallet to ensure it is

correctly seated on the flywheel.

2. Check the clutch run-out does not exceed 0.381 mm

(0.015 in) on the steel thrust disc.

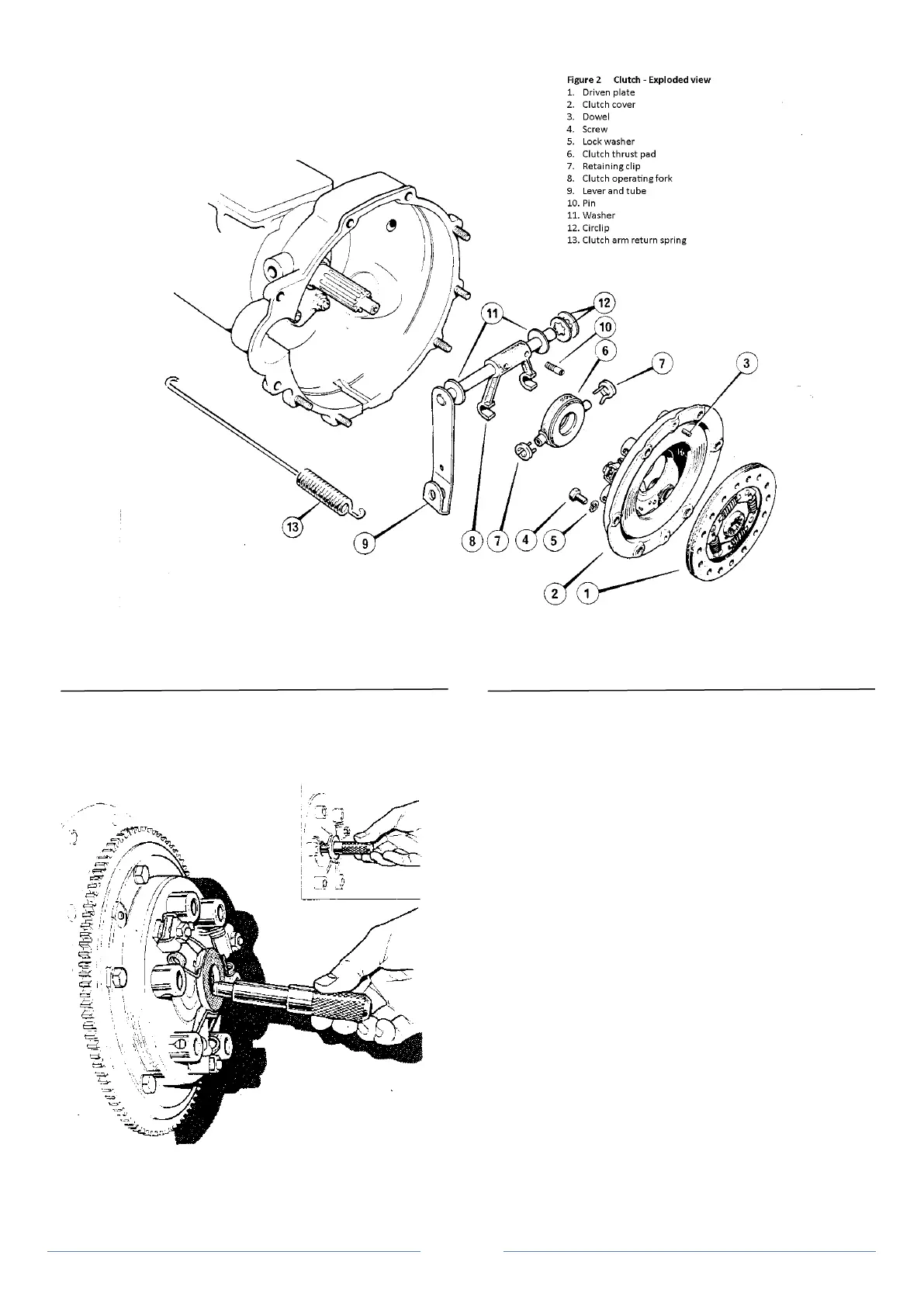

Operation 3 Clutch operating fork, lever and thrust pad

Removal and replacement

The operating fork is pinned into position on the shaft of the clutch

lever and tube assembly which is pivoted through the top of the

gearbox bell housing. To ensure that the thrust pad moved in the

correct plane it is pivoted in the operating fork and held firm by lock

springs. (Figure 2)

To remove

1. \\remove gearbox (Section G).

2. Using a screwdriver, prise off the locking washers and plain

washer, securing the clutch lever shaft to the bell housing.

3. Tap out the two clutch fork retaining mills pins with a 3.175

mm (0.125 in) diameter drift.

Note: It is advantageous to first remove the right-hand pin to facilitate

easier withdrawal.

4. Withdraw the clutch lever and shaft assembly from the

gearbox bell housing and remove the clutch fork.

Loading...

Loading...