Page 70

Figure 12 Determining pinion mounting distance using dummy

pinion

Figure 13 Replacing pinion bearing cone using hand press and collars

1. Collars

2. Adaptor

3. Spacing washer

pinion shank, this means it has been manufactured high and requires

reducing in height by the same distance. Therefore if the gap

measured is, say 0.044, the spacers required will be 0.44 minus 0.030

minus 0.003 which will equal spacers to the value of 0.011 thicker

than that used for measurement.

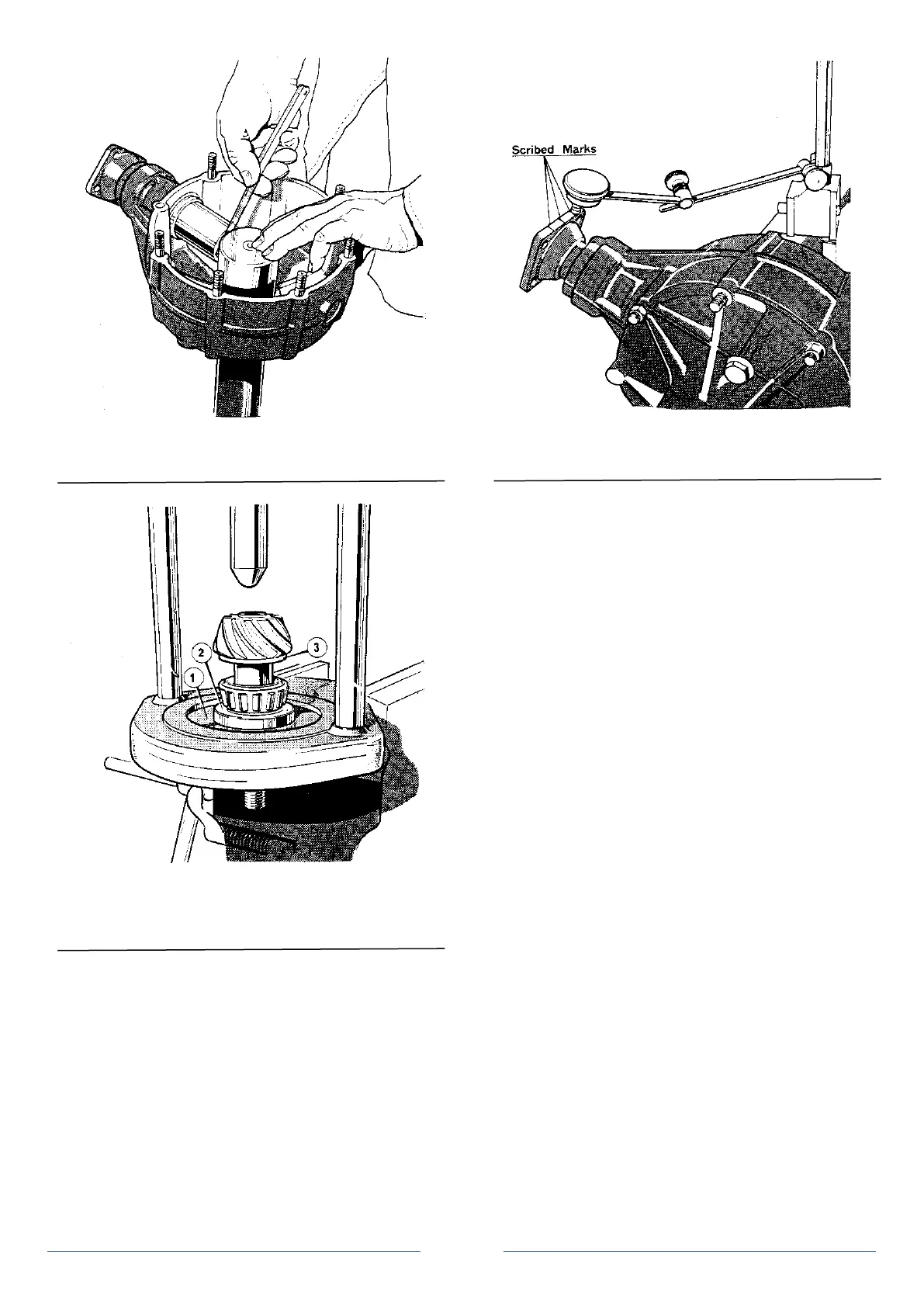

5. Remove the dummy pinion assembly, place the selected

spacer on the pinion and assemble the bearing cone, using the hand

press tool No. 47, adapter RT 8765/2 and bearing replacer collars RT

8765/1 (Figure 13)

Operation 6 Re-assembly - installation of pinion in axle case

1. Add the collapsible spacer to the pinion assembly and place

the new oil seal in the pinion housing. Place the pinion assembly in the

pinion housing and replace the pinion flange and the nyloc nut.

Figure 14 Determining pinion to crown wheel backlash using a

dial gauge

2. Using a torque wrench, progressively collapse the spacer

starting at 6.91 kg/m (50 lb/ft). Preload begins when end float is

eliminated at approximately 11.06 kg/m (80 lb/ft).

3. Turn the pinion to ensure that the pinion rollers are

correctly seated.

4. Using a torque meter, check the torque required to turn the

pinion nut. This should be set at 0.150 to 0.184 kg/m (13 to 16 lb/in).

Operation 7 Re-assembly - determining the correct backlash,

crown wheel to pinion

1. Replace the differential assembly complete with the

dummy bearings into the differential housing and secure the two

halves of the axle case together.

2. If removed, refit the push rods of tool No. RT8732 as for

setting the differential end float. Slacken the right-hand side and then

screw in the left-hand push rod as before, using a torque wrench set

to 0.28 to 0.55 kg/m (2 to 4 lb/ft) maximum. This will give minimum

backlash. Screw up the gauging nut lightly to the face of the disc and

lock in position with the lock nut as before.

3. Unscrew the left-hand side and screw in the right-hand side

until the correct backlash is obtained. This should be checked at the

pinion flange as follows:

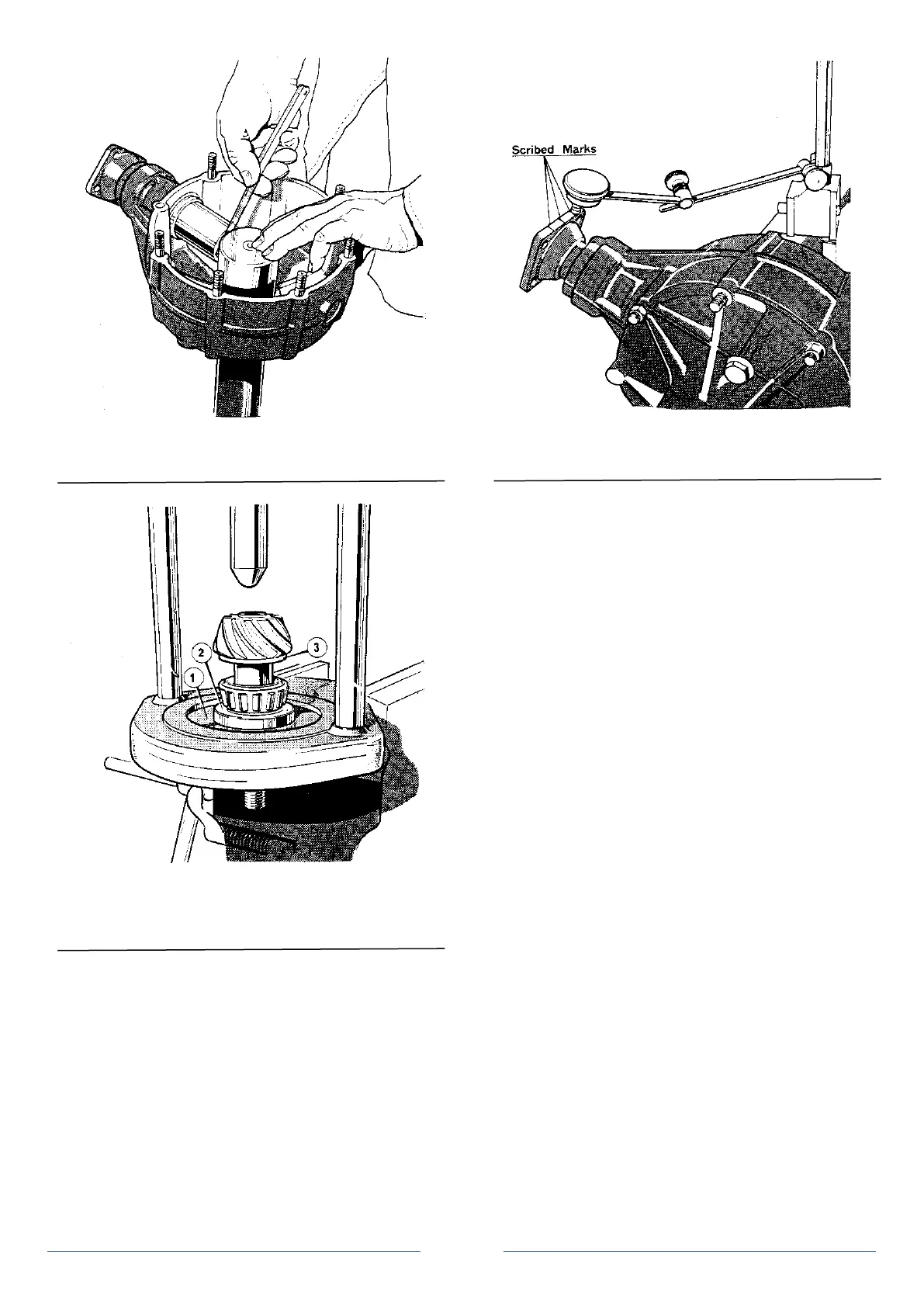

Setting the correct backlash, pinion to crown wheel, using a dial

gauge

1. With pinion flange horizontal, scribe a centre line on the

top end of the flange and a line 7/8 in on either side of it. (Figure 14).

This represents the overall diameter of the pinion.

2. Set up a dial gauge indicator on a magnetic base as shown

in Figure 14.

3. Using a screwdriver through the level/filler aperture, lock

the crown wheel by wedging it in between the pinion flange and the

bolt heads.

4. Rock the pinion flange and read off the backlash readings.

This should measure 0.006 to 0.008 in.

5. Screw in the left-hand side until a stop is felt, screw up

right-hand side until contact is made. Measure minimum backlash.

Unscrew left-hand rod and tighten right-hand rod at approximately

half turn intervals until the correct backlash is obtained.

Loading...

Loading...