Page 72

Section L

Contents

Description

Routine maintenance and adjustments

Operation 1 Check front brake lining and adjustment

Operation 2 Check rear brake lining and adjustment

Operation 3 Handbrake adjustment

Handbrake cable lubrication

The hydraulic system

Operation 4 Bleeding the hydraulic system

Operation 5 Front brakes - fitting new shoes

Operation 6 Front wheel cylinders - removal & replacement

Operation 7 Rear brakes - fitting new shoes

Operation 8 Rear wheel cylinders - removal & replacement

Operation 9 Master cylinder - removal & replacement

Brake pedal assembly

Operation 10 Handbrake cable - replacement

Operation 11 Handbrake lever - removal & replacement

Dual circuit braking system

Description

The hydraulic braking system operates drum brakes at both front and

rear. A mechanical handbrake linkage is provided, operating on the

rear brakes only. The brake pedal, connected directly to the master

cylinder via a short push rod, also incorporates a stop light switch

mounted on the pedal bracket assembly.

Routine maintenance and adjustments

Check the level of the brake master cylinder weekly and top-up if

necessary.

Every 6,000 miles (10,000 km)

Adjust brakes.

Check and grease handbrake cable.

Check, bleed if necessary and top up the hydraulic system.

Inspect the hydraulic system for leaks and chafing.

Every 36,000 miles (60,000 km)

Replace fluid, renew seals or replace units, replace hoses.

Operation 1 Check front brake lining and adjustment

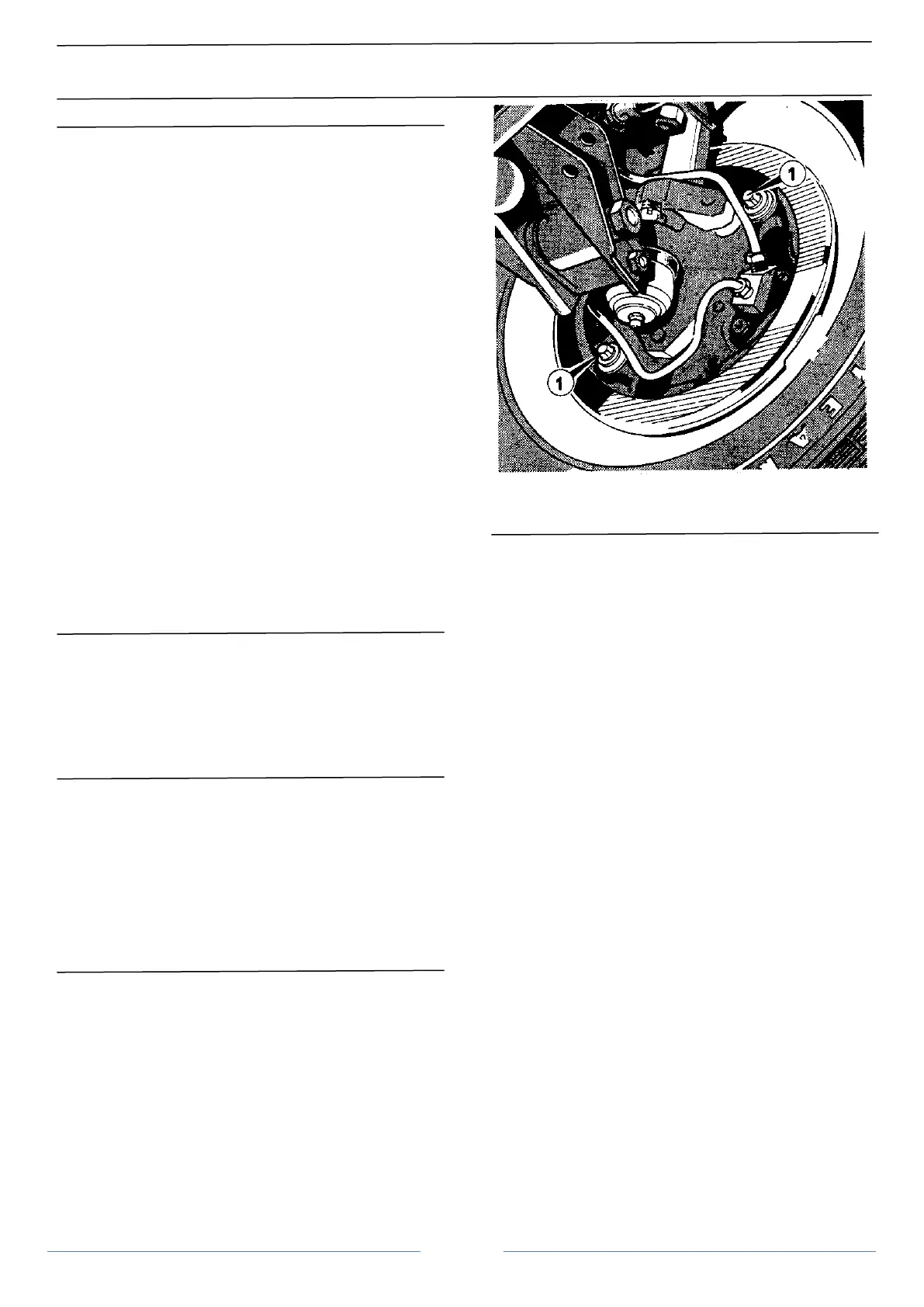

A manual eccentric pin type brake adjuster is fitted to both brake

shoes (Figure 1).

1. Check brake drums are cold.

2. Jack up the vehicle until the front wheel is clear of the

ground.

]

Brakes

Front brake adjusters

1. Adjuster

3. Remove the road wheel and fully slacken off the brake

adjusters.

4. Remove the front brake drum.

5. Check the lining material thickness. Linings that are bonded

to the shoes must not be allowed to wear below 1.5 mm (1/16 in) in

thickness. Riveted linings should be changed when the material wears

within 0.75 mm (1/32 in) of the rivet heads.

6. If the linings are serviceable refit the brake drum, locating

the larger stud hole over the stud with a collar on it (this is to preserve

the balance of the hub/drum assembly).

7. Replace the road wheel and adjust as follows: Turn the

adjuster of one shoe to bring the lining away from the shoe (in the

opposite direction to wheel rotation). Turn the other adjuster in the

direction of wheel rotation until the drum is locked. Then slacken back

until the wheel is sufficiently free to rotate without binding.

8. Rotate the other adjuster in the direction of wheel rotation

until the drum is locked. Again back off until the wheel is just

sufficiently free to turn without binding.

Note: This minimum adjustment must be performed accurately to

obtain the minimum clearance between the shoe linings and drum,

with consequent minimum pedal travel.

Repeat with the opposite wheel.

Operation 2 Check rear brake lining and adjustment

1. Jack up the vehicle until one rear wheel is clear of the

ground.

2. Check the linings as described for the front wheel.

3. If the linings are serviceable, replace the drum and road

wheel and adjust as follows:

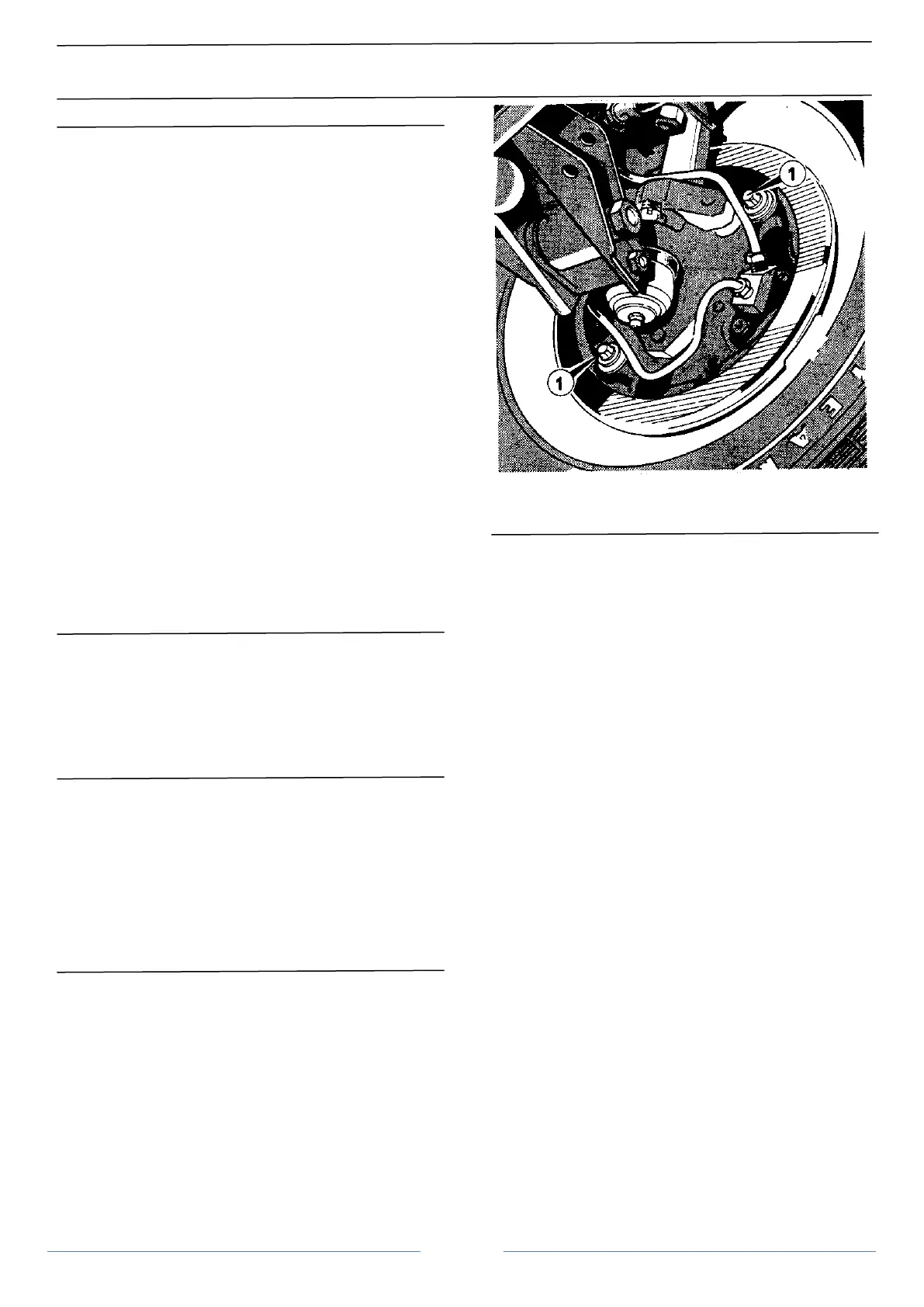

Release the handbrake and whilst rotating the wheel, turn the

adjuster (Figure 2) clockwise until the shoes touch the drum. Continue

"one click" at a time until the drum is locked. Slacken the adjuster

"two clicks" when the wheel should rotate freely. repeat with the

other wheel.

Loading...

Loading...