13

Tubing

INSTALLATION

Interconnecting Tubing (cont�)

Example: A 3-Ton condensing unit is installed 50’

below the ID unit, requires a 75’ of 1/2” diameter

liquid line, and 4 90° LR elbows�

• Fitting Equivalent Length (ft�) = 4 x �9 = 3�6’

• Total Equivalent Length (ft�) = 75’ + 3�6’ = 78�6’

• Rounded-down value (ft�) = 75’

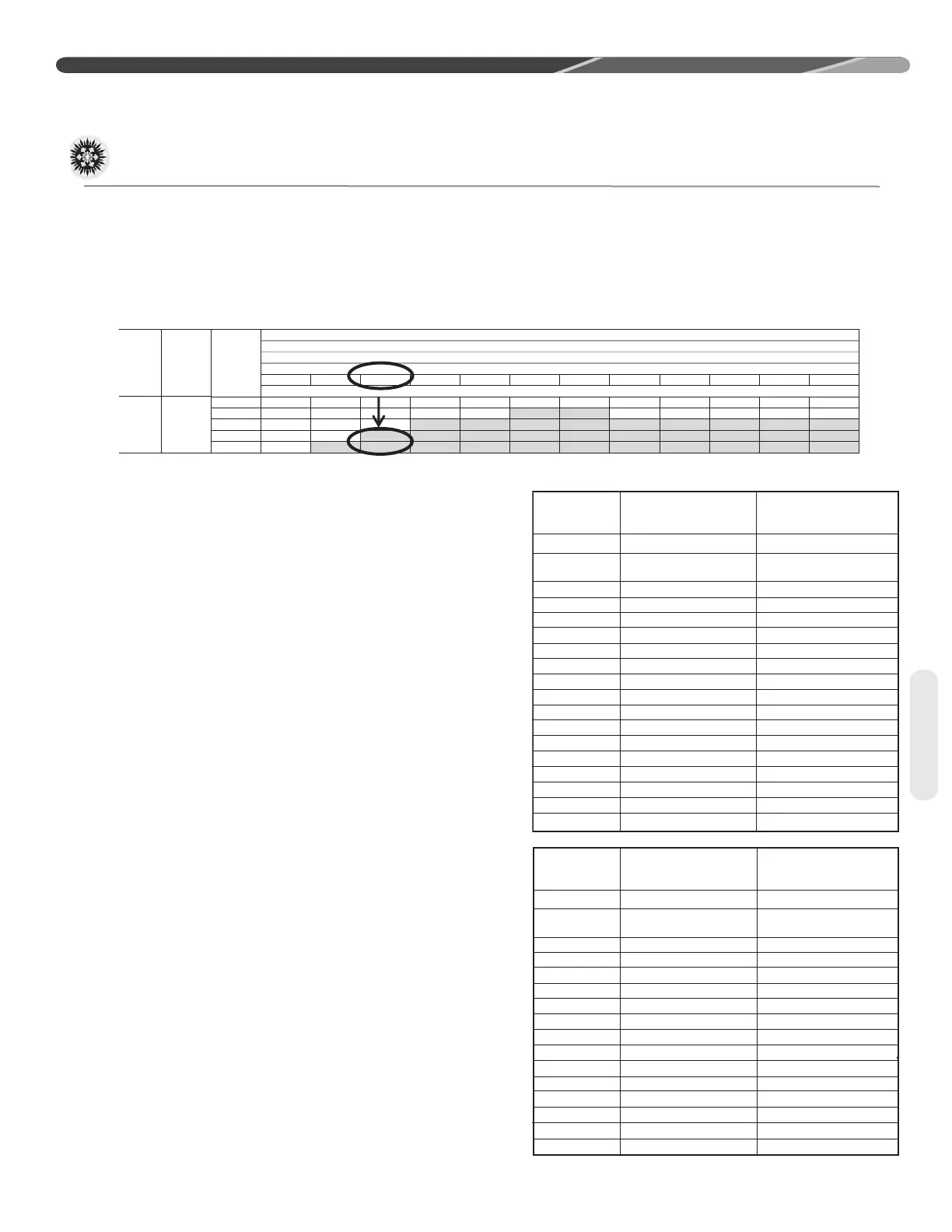

R-410A

System

Capacity

Model

Liquid Line

Size

Connection

Size (Inch

I.D.) [mm]

Liquid Line

Size (Inch

O.D.) [mm]

Liquid Line Size

Elevation (Above or Below) Indoor Coil

Total

Equivalent

Length - Feet [m]

25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 125 [45.72] 150 [45.72] 175 [53.34] 200 [60.96] 225 [68.58] 250 [76.20] 275 [83.82] 300 [91.44]

Maximum

Vertical Separation - Feet [m]

37 3/8" [9.53]

1/4 [6.35] 25 [7.62]

N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

5/16 [7.94] 25 [7.62] 50 [15.24] 60 [18.29] 45 [13.72] 35 [10.67] 20 [6.1] 5 [1.52]

N/R N/R N/R N/R N/R

3/8 [9.53] 25 [7.62] 50 [15.24] 75 [22.86] 80 [24.38] 80 [24.38] 75 [22.86] 70 [21.34] 65 [19.81] 60 [18.29] 55 [16.76] 50 [15.24] 45 [13.72]

7/16 [11.12] 25 [7.62] 50 [15.24] 75 [22.86] 95 [28.96] 90 [27.43] 90 [27.43] 85 [25.91] 85 [25.91] 85 [25.91] 80 [24.38] 80 [24.38] 80 [24.38]

1/2 [12.71] 25 [7.62] 50 [15.24] 75 [22.86] 95 [28.96] 95 [28.96] 95 [28.96] 95 [28.96] 95 [28.96] 95 [28.96] 90 [27.43] 90 [27.43] 90 [27.43]

This application is acceptable because the 50’

vertical rise is less than the maximum rise of 75’ for

this application� The application is also considered

to have a long line set� Reference the long line set

section of the I&O for detail�

Long Line Set Applications

Long line set applications are dened as ap-

plications that require accessories or alternate

construction methods� The following are special

considerations that need to be addressed when

installing a long line set application:

• Additional refrigerant charge

• Fitting losses and maximum equivalent length

considerations

• Refrigerant migration during the o cycle

• Oil return to the compressor

• Capacity losses

• System oil level adjustment

Table 2 is used to determine if the application is

considered to have a long line set� The region of

the chart that is shaded grey is considered to

be a long line set application.

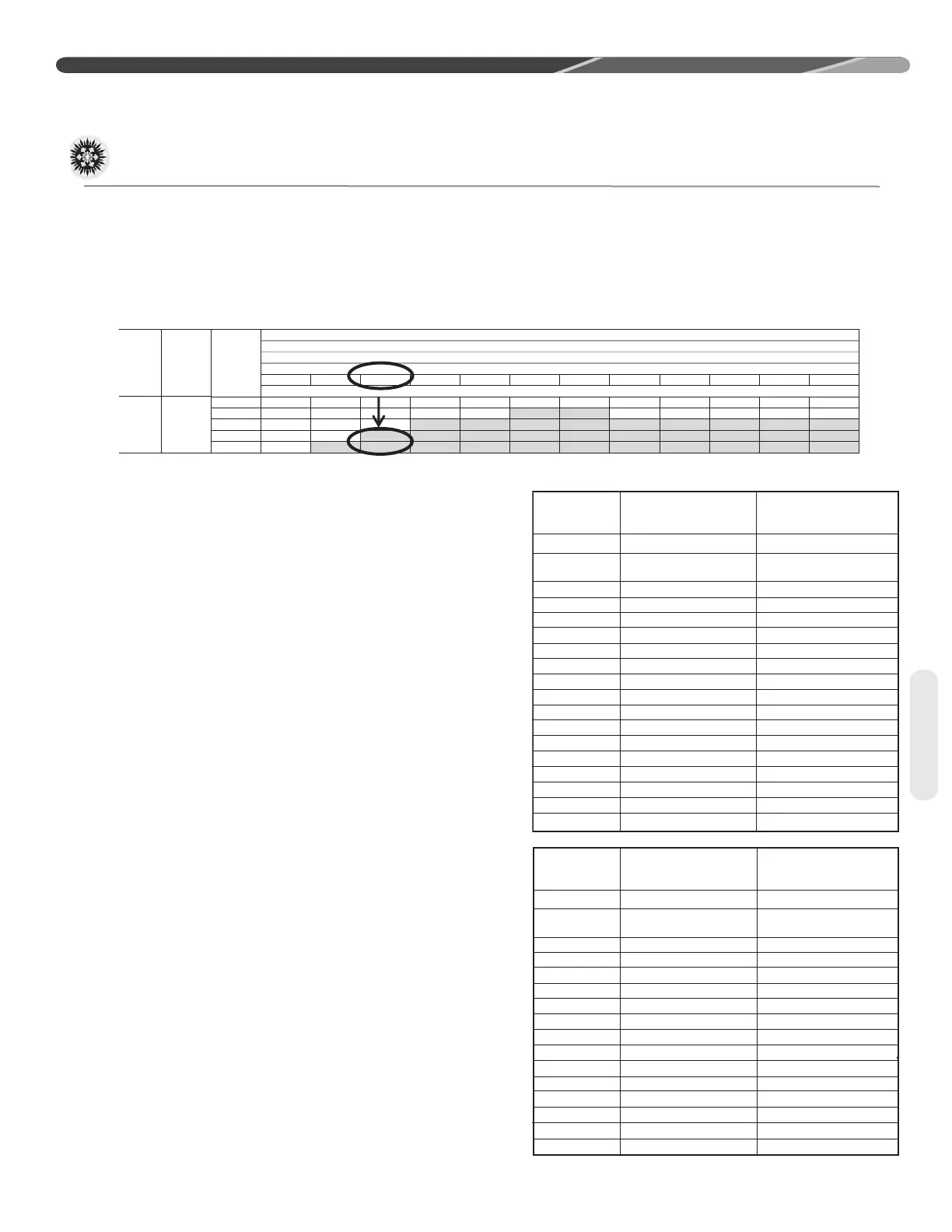

Oil Level Adjustments for

Long Line Set Applications

Additional oil will need to be added for long line set

applications� (Ref� Table 2)� Below is the equation

for the oil level adjustment and the compressor

name plate oil charge for the dierent od units.

Oil to be Added = [(Charge Adjustment + OD

Unit Name Plate Charge (oz.)) x (0.022) – [(0.10)

x (Compressor Name Plate Oil Charge (oz.))]

Example: An application requires 125ft of line set

with a liquid line diameter of 3/8”, Charge Adjust-

ment = 52�4 oz�, Name Plate Charge = 107 oz�,

Name Plate Oil Charge = 25 oz�, Oil to be Added =

((52�4 oz� +107 oz�) x �022) – (�10 x 25 oz�) = 1�0 oz�

(excerpt fromTable 2, page 16)

RA13

OD Model

Compressor

Name Plate Oil

Charge (oz)

RA1318AJ

RA1318AJ

Alternate

RA1324AJ

RA1330AJ

RA1336AJ

RA1342AJ

RA1348AJ

RA1360AJ

RA1336AC

RA1342AC

RA1348AC

RA1360AC

RA1336AD

RA1342AD

RA1348AD

RA1360AD

RA1348AY

RA1360AY

ZP14KAE-PFV-130

ZP14K6E-PFC-130

ZP20KAE-PFV-130

ZP24K5E-PFV-130

ZP31K6E-PFV-130

ZP34K5E-PFV-130

ZP42K5E-PFV-130

ZP51K5E-PFV-130

ZP31K6E-TF5-130

ZP34K5E-TF5-130

ZP42K5E-TF5-130

ZP51K5E-TF5-130

ZP31K6E-TFD-130

ZP34K5E-TFD-130

ZP42K5E-TFD-130

ZP51K5E-TFD-130

ZP42K5E-TFE-130

ZP51K5E-TFE-130

21

21

21

25

25

42

42

42

25

42

42

42

25

42

42

42

42

42

RA14

OD Model

Compressor

Name Plate Oil

Charge (oz)

RA1418AJ

RA1418AJ

Alternate

RA1424AJ

RA1430AJ

RA1436AJ

RA1442AJ

RA1448AJ

RA1460AJ

RA1436AC

RA1442AC

RA1448AC

RA1460AC

RA1436AD

RA1442AD

RA1448AD

RA1460AD

ZP14KAE-PFV-130 21

21

21

25

25

42

42

42

25

42

42

42

25

42

42

42

ZP14K6E-PFC-130

ZP20KAE-PFV-130

ZP24K5E-PFV-130

ZP29K5E-PFV-130

ZP34K53-PFV-130

ZP39K5E-PFV-130

ZP49K6E-PFV-130

ZP31K6E-TF5-130

ZP34K5E-TF5-130

ZP42K5E-TF5-130

ZP51K5E-TF5-130

ZP31K6E-TFD-130

ZP34K5E-TFD-130

ZP42K5E-TFD-130

ZP51K5E-TFD-130

Loading...

Loading...