142

MO-C1 Training

Slide 142

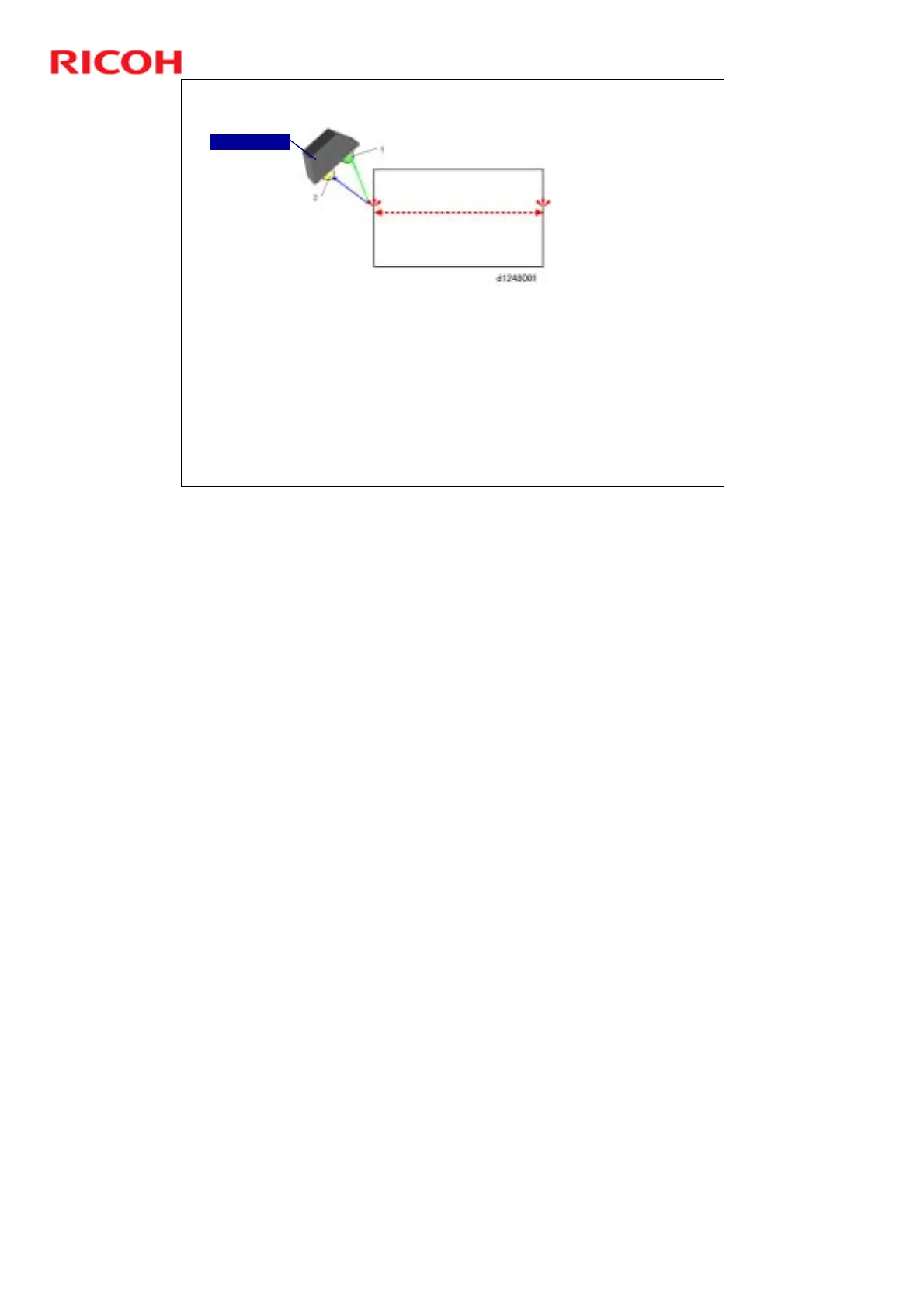

General Operation Sequence

3. Paper Feed

To check for paper skew:

The carriage moves to the left and the DRESS sensor, mounted on the left side of the carriage,

checks the right edge of the paper. The machine feeds more paper and then the sensor checks the

right edge again.

If the 1st and 2nd readings deviate by more than ±10 mm, this indicates excessive skew.

The paper is rewound and the operator must set the paper again.

If no skew is detected, the paper is fed into the machine. Then the paper feed motor reverses while

the vertical motor continues to feed the paper forward. This takes up slack in the paper, and then

both motors turn OFF.

Then skew is checked again, but the tolerance this time is ±5 mm.

If the deviation is within ±5 mm, paper registration ends and the paper is reverse fed as far as the

registration roller. This is the registration standby position and the machine is ready to start printing.

If the deviation is not within ±5 mm, the paper is released, the machine rewinds the paper and then

fed again, slack is removed again, and ±5 mm skew checked again.

During the above process, the carriage moves to the left side of the machine and the DRESS

sensor detects the left edge of the paper. This detection of the right and then the left edge of the

paper is for paper width detection and image registration.

DRESS Sensor

No additional notes

Loading...

Loading...