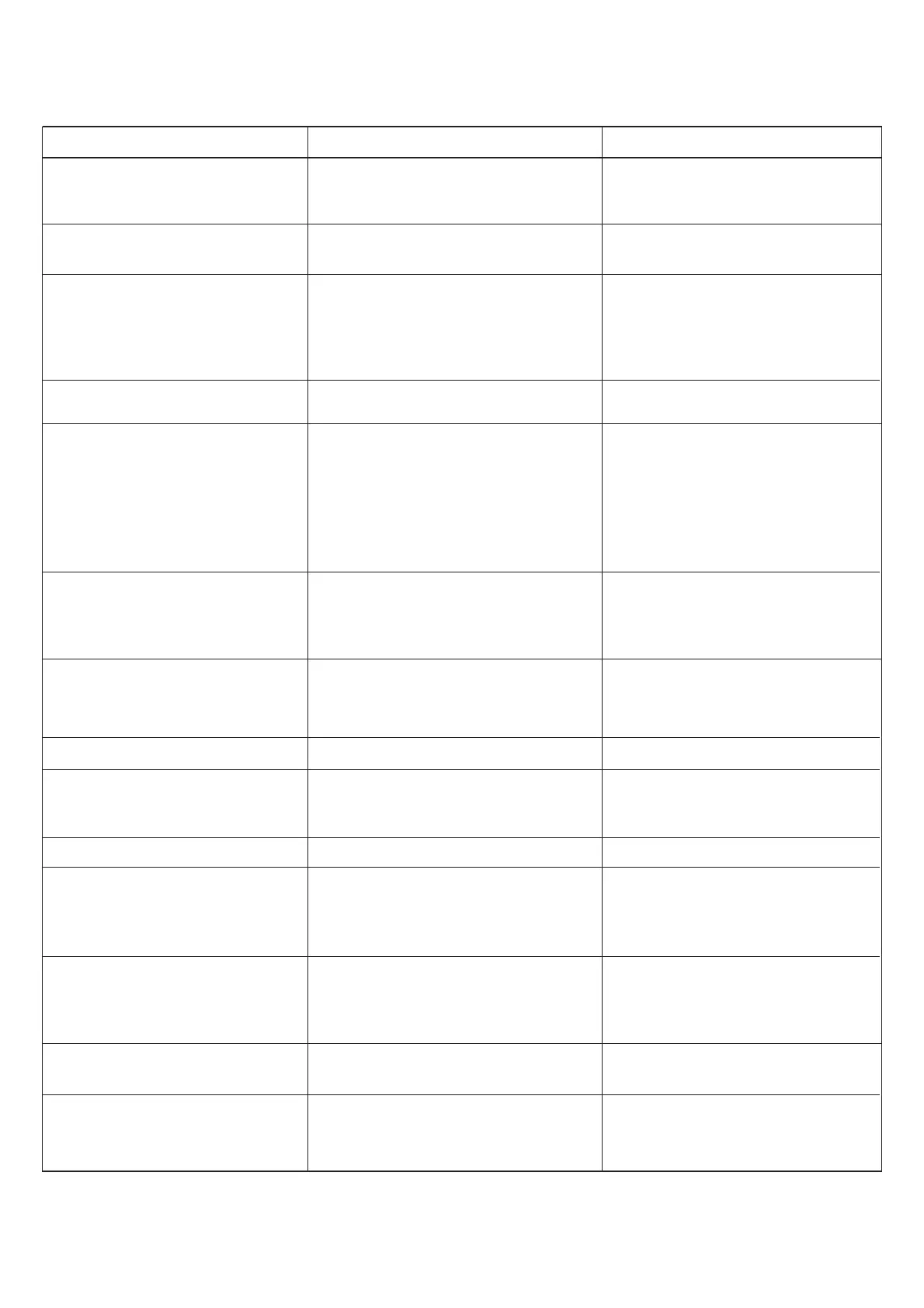

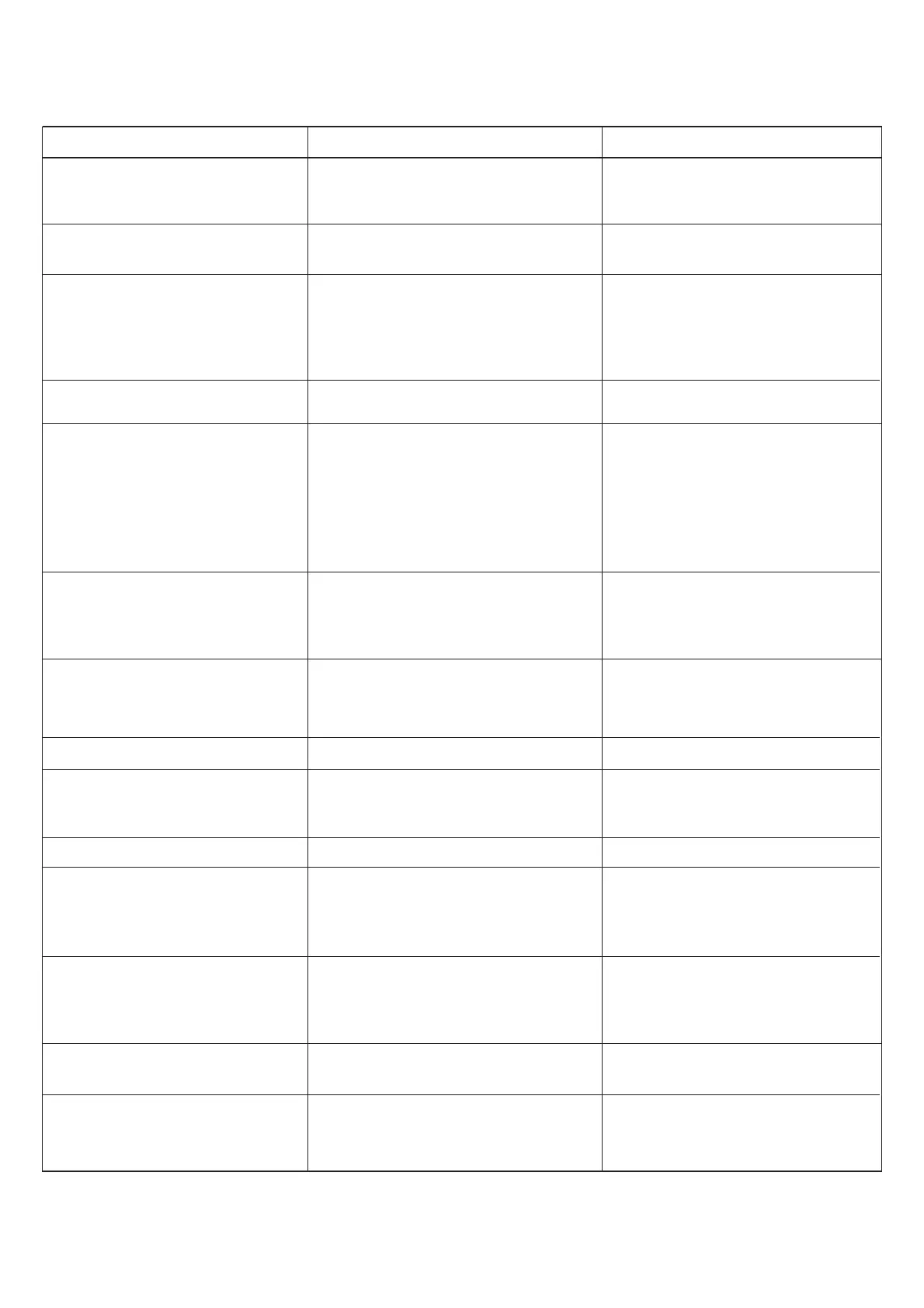

Table 3. Troubleshooting

Malfunction Probable Cause Corrective Action

1. Rolled groove too narrow or too wide. a. Incorrect size of grooving and driving rolls. a. Install correct size of grooving and driving rolls.

b. Mismatched grooving and driving rolls. b. Match grooving and driving rolls.

c. Grooving roll and/or driving roll worn. c. Replace worn roll.

2. Rolled groove not perpendicular to pipe axis. a. Pipe length not straight. a. Use straight pipe.

b. Pipe end not square with pipe axis. b. Cut pipe end square

3. Pipe will not track while grooving. a. Pipe not level. a. Adjust stand to level pipe.

b. Pipe axis not offset 1/2 degree from driving roll axis. b. Offset pipe 1/2 degree (See Fig.14, 15)

c. Pipe axis not offset in the correct direction. c. See set-up instructions.

d. Groover not level. d. Level groover.

e. Feed Screw not tight. (914) e. Tighten feed screw with ratchet for every

revolution.

4. Pipe drifts back and forth. a. Pipe length not straight. a. Use straight pipe.

on driving roll axis while grooving. b. Pipe end not square with pipe axis. b. Cut pipe end square.

5. Pipe rocks from side to side a. Pipe end flattened or damaged. a. Cut off damaged pipe end.

on driving roll while grooving. b. Hard spot in pipe material or weld seams b. Use high quality pipe of uniform hardness.

harder than pipe.

c. Power drive rotating pipe too fast. c. Reduce speed - shift to low speed or use RIDGID

36 rpm 300, 535, 1233, 1224 or 1822 Power

Drive.

d. Pipe support stand rollers not in correct d. Position pipe stand rollers for pipe size being used.

location for pipe size.

e. Grooving Roll feed rate too slow (914) e. Hand feed Grooving Roll into pipe faster.

6. Groover will not roll groove in pipe. a. Pipe wall maximum thickness exceeded a. Check pipe capacity chart.

b. Wrong rolls. b. Install correct rolls.

c. Adjustment nut not set. c. Set depth.

d. Power drive does not supply required d. Use RIDGID No. 300, 535, 1224, 1233

minimum torque. or 1822 Power Drive.

7. Groover will not roll groove to specification. a. Maximum pipe diameter tolerance exceeded a. Use correct diameter pipe

b. Mismatched grooving and driving rolls. b. Use correct set of rolls.

c. Pipe material too hard. c. Replace pipe.

d. Adjustment screw not set (914/916) d. Set depth.

8. Pipe slips on driving roll. a. Driving roll knurling plugged with metal or worn flat. a. Clean or replace driving roll.

9. Groover will not rotate pipe while grooving. a. Grooving Roll hand feed rate too slow (914/916). a. Hand feed Grooving Roll into pipe faster.

b. Power drive does not supply minimum b. Use RIDGID No. 300,535, 1224, 1233 or 1822

required torque. Power Drive.

c. Chuck not closed on drive shaft flats. c. Close chuck

10.Power Drive & Groover tend to tip. a. Not enough support for pipe. a. Use (2) pipe stands for all lengths over 36".

11.Pump not delivering oil, cylinder a. Pump release valve open. a. Close release valve

does not advance. b. Low oil in reservoir. b. Check oil lever per instructions.

(918 only) c. Dirt in pump body. c. Requires service by qualified technician.

d. Seats worn or not seating. d. Requires service by qualified technician.

e. Too much oil in reservoir. e. Check oil level per instructions.

12.Pump handle operates with "spongy" action a. Air trapped in system. a. Position ram lower than pump by tipping the

(918 only) machine on its side opposite the operator.

Extend and return the cylinder piston several times

to permit air to return to the pump reservoir.

b. Too much oil in reservoir. b. Check oil level per instructions.

13.Cylinder extends only partially. a. Pump reservoir is low on oil. a. Fill and bleed system.

(918 only) b. Depth and adjustment set incorrectly. b. Follow depth adjustment instructions.

14.Pipe end flares or forms bell shape a. Operator is advancing grooving rolls too fast. a. Slow down pumping action. Refer to proper

when grooving operating instructions.

(918 only) b. Pipe not level. b. Adjust stand to level pipe with groover.

www.ridgitool.com Официальный дистрибьютор в России с 1996 года (812) 936-02-07, 331-37-51

Loading...

Loading...