How to fix a roll groove that is too narrow or too wide on a RIDGID 916 Power Tool?

- Rrobert10Oct 25, 2025

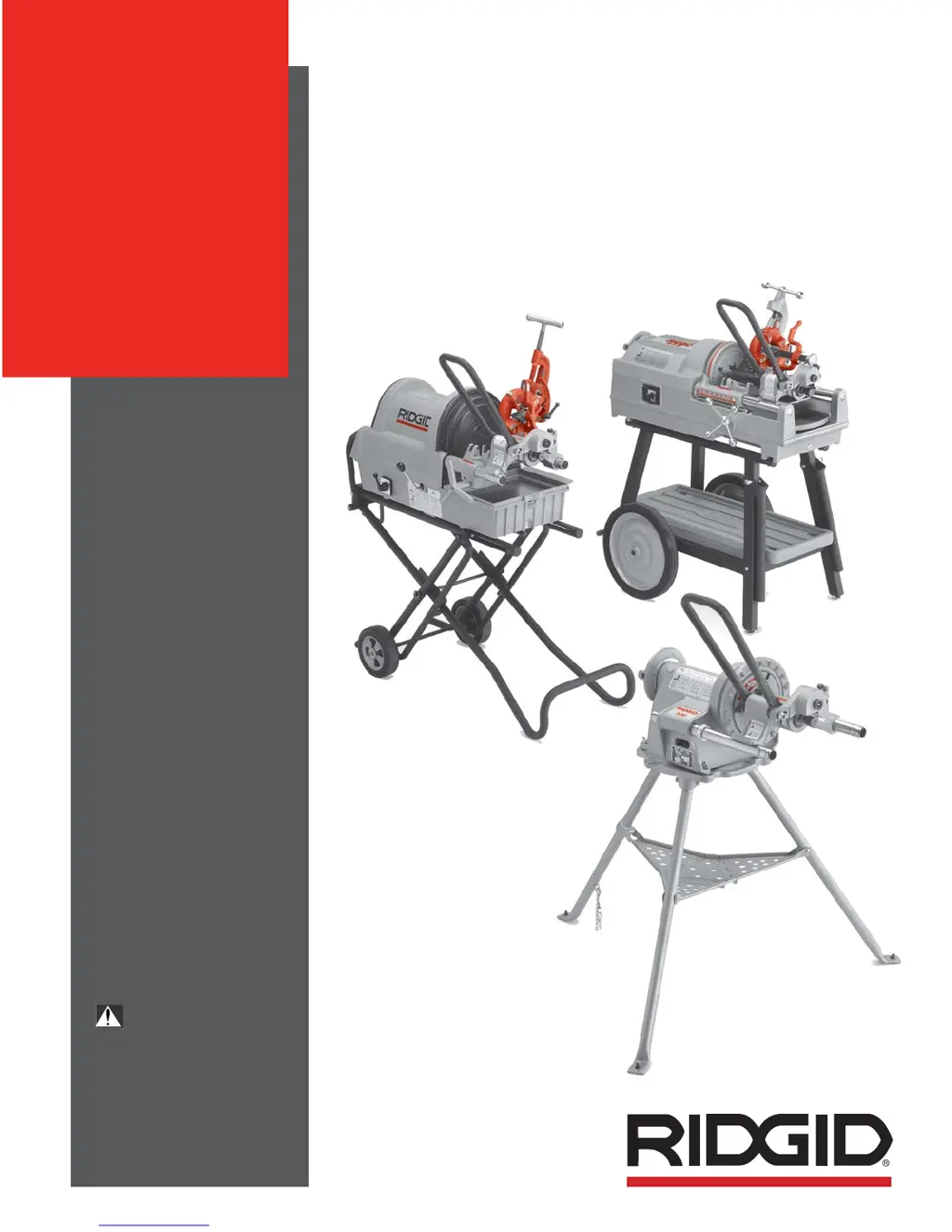

If the roll groove is too narrow or too wide on your RIDGID Power Tool, several factors could be at play. First, ensure you have the correct size of grooving and driving rolls installed and that they are properly matched. Inspect the rolls for wear and replace them if necessary. Verify the pipe length is straight, the end is square with the pipe axis, and the pipe is level, adjusting the stand as needed. Make sure the pipe axis is offset 1/ degree from the driving roll axis and that the groover is level. Position pipe stands correctly, away from the pipe end. Address any pipe end damage by cutting it off. Increase the hand feed rate of the grooving roll, and reduce the power drive speed to 36 RPM. Ensure pipe stand rollers are correctly positioned for the pipe size. Check the pipe capacity...