16

008082013GW

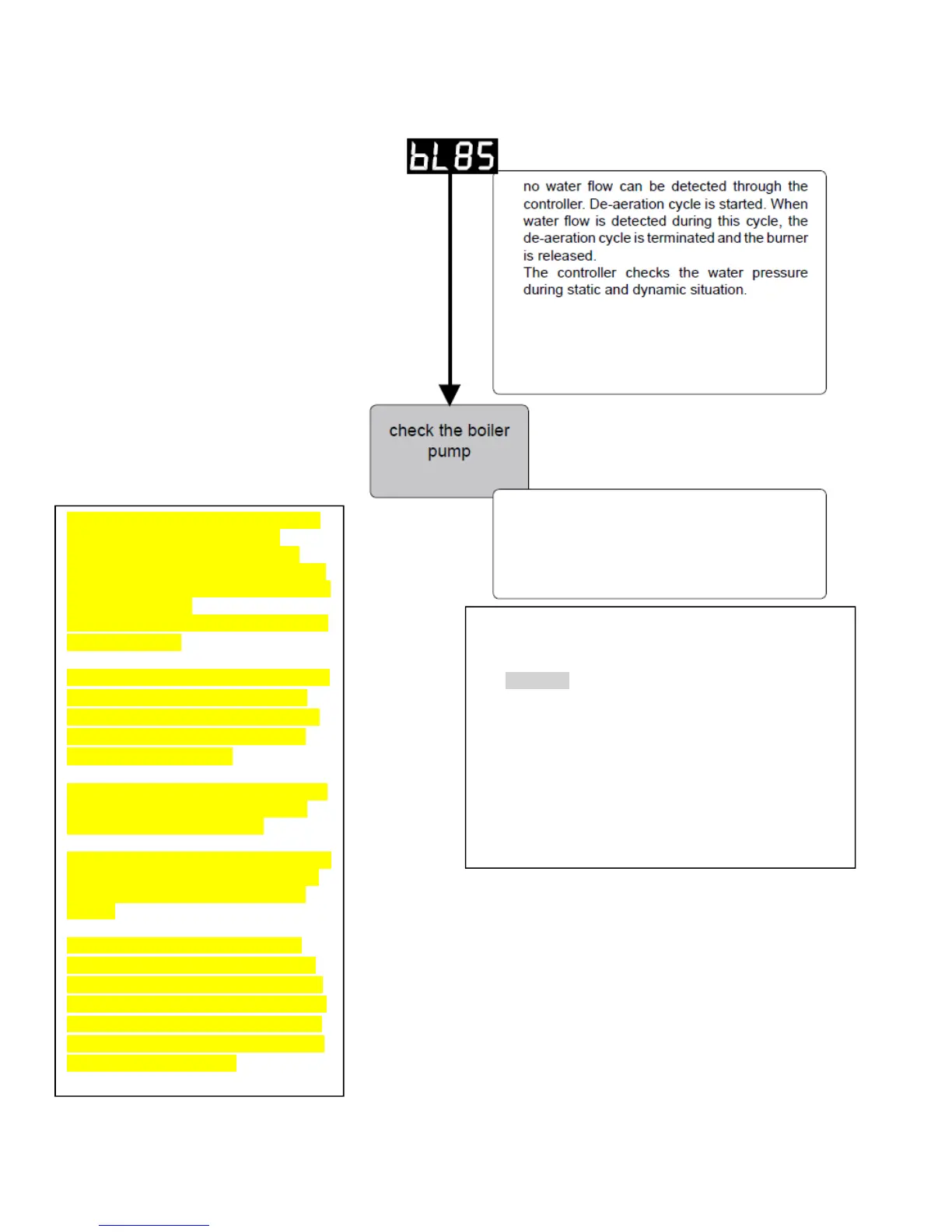

Check the installation for the presence of air.

If there is a secondary pump installed and it

is not hydraulically separated, it could cause

a loss of pressure difference.

Check to ensure the pump is functioning and/or water

pressure sensor is working properly.

WARNING: Turn off power and water supply to the boiler

before removing or installing any parts.

Ensure water pressure sensor is not clogged or defective.

Inspect water filter for debris.

Check pump for proper operation and flow rates.

Check for proper wiring of pump.

Check for use of balancing valves.

AIR: if boiler, inner boiler piping, or Low Loss

Header has a large air bubble in it the

pressure sensor will not see the pressure

spike that the pump generates when it starts.

The pressure spike is what tells the MCBA that

the pump has started.

The air bubble will absorb that spike. Bleed all

air from the system.

If an additional expansion tank is placed in the

system alongside an E-boiler that tank can

absorb the pump pressure spike as well. You

may need to isolate that tank to see if this

corrects the issue with BL 85.

An expansion that is not charged properly can

cause the pump’s pressure spike not to be

seen by the sensor causing a BL85.

Expansion tank pressure should be air charged

to match whatever water fill pressure that is

chosen for the closed loop. (Always above

14.5 psi)

Expansion tanks must be air charged only

when there is no water pressure on the wet

side of the diaphragm or the tank is removed

from the system. Once charged to the correct

air pressure it may be placed into the system

and the water fill pressure now may be set to

match the new tank pressure.

Loading...

Loading...