NOTES:

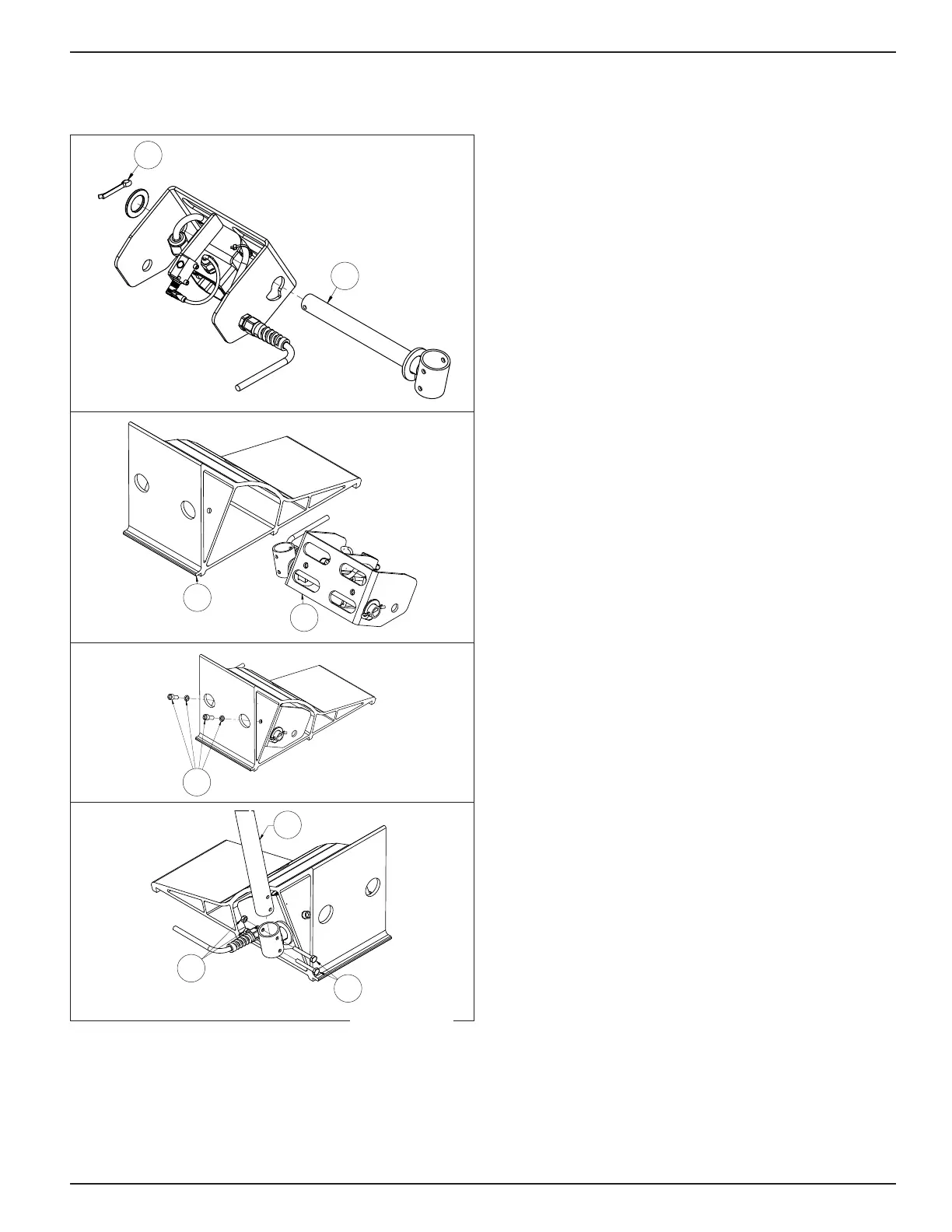

STEP 9

1) REINSTALL SHAFT AND SHAFT RETAINING HARDWARE AS SHOWN.

STEP 10

1) REINSTALL GWC ASSEMBLY BACK INTO CHOCK AS SHOWN.

N

OT

R

EL

EAS

E

D

CONFIDENTIAL

PRODUCTS CORPORATION.

=

PRODUCTS CORPORATION

REV

SHEET

TITLE

SIZE

SCALE

DWG NO

®

© 2019 RITE-HITE®

REVISION STATUS

DRAWN BY

RESPONSIBLE ENGINEER

DO NOT SCALE DRAWING

MATERIAL

INSTR MODFY GWC1 BARR ORIENT

C

0159009

--

1:4 5 OF 6

THIRD ANGLE PROJECTION

.060

.X

.030

ALL SHEETS ARE THE SAME

.XX

TOLERANCES:

A

B

C

D

D

C

B

A

4

3

2

1

4

321

UNLESS OTHERWISE SPECIFIED

.XXX

ANGLE

MANUFACTURING ENGINEER

B. WIEBERDINK

=

FINISH

DIMENSIONS ARE IN INCHES.

REFERENCE

2.0

WEIGHT

G. PROFFITT

= .120

=

THIS DOCUMENT IS THE PROPERTY

OF RITE-HITE® PRODUCTS

CORPORATION SUBJECT MATTER

HEREIN IS CONFIDENTIAL. DO NOT

USE, REPRODUCE, COPY OR

DISCLOSE EXCEPT WITH WRITTEN

CONSENT OF RITE-HITE®

PRODUCTS CORPORATION

STEP 9

HARDWARE

SHAFT

STEP 10

GWC ASSEMBLY

CHOCK

REV DATE DESCRIPTION ECN APPROVED BY

A 06/05/2019 RELEASE TO PRODUCTION 20190145 G. PROFFITT

REVISION HISTORY

J2

J1

NOTES:

STEP 9

1) REINSTALL SHAFT AND SHAFT RETAINING HARDWARE AS SHOWN.

STEP 10

1) REINSTALL GWC ASSEMBLY BACK INTO CHOCK AS SHOWN.

N

OT

R

EL

EAS

E

D

CONFIDENTIAL

PRODUCTS CORPORATION.

=

PRODUCTS CORPORATION

REV

SHEET

TITLE

SIZE

SCALE

DWG NO

®

© 2019 RITE-HITE®

REVISION STATUS

DRAWN BY

RESPONSIBLE ENGINEER

DO NOT SCALE DRAWING

MATERIAL

INSTR MODFY GWC1 BARR ORIENT

C

0159009

--

1:4 5 OF 6

THIRD ANGLE PROJE CTION

.060

.X

.030

ALL SHEETS ARE THE SAME

.XX

TOLERANCES:

A

B

C

D

D

C

B

A

4

3

2

1

4

321

UNLESS OTHERWISE SPECIFIED

.XXX

ANGLE

MANUFACTURING ENGINEER

B. WIEBERDINK

=

FINISH

DIMENSIONS ARE IN INCHE S.

REFERENCE

2.0

WEIGHT

G. PROFFITT

= .120

=

THIS DOCUMENT IS THE PROPERTY

OF RITE-HITE® PRODUCTS

CORPORATION SUBJECT MATTER

HEREIN IS CONFIDENTIAL. DO NOT

USE, REPRODUCE, COPY OR

DISCLOSE EXCEPT WITH WRITTEN

CONSENT OF RITE-HITE®

PRODUCTS CORPORATION

STEP 9

HARDWARE

SHAFT RETAINING

SHAFT

STEP 10

GWC ASSEMBLY

CHOCK

REV DATE DESCRIPTION ECN APPROVED BY

A 06/05/2019 RELEASE TO PRODUCTION 20190145 G. PROFFITT

REVISION HISTORY

K1

K2

NOTES:

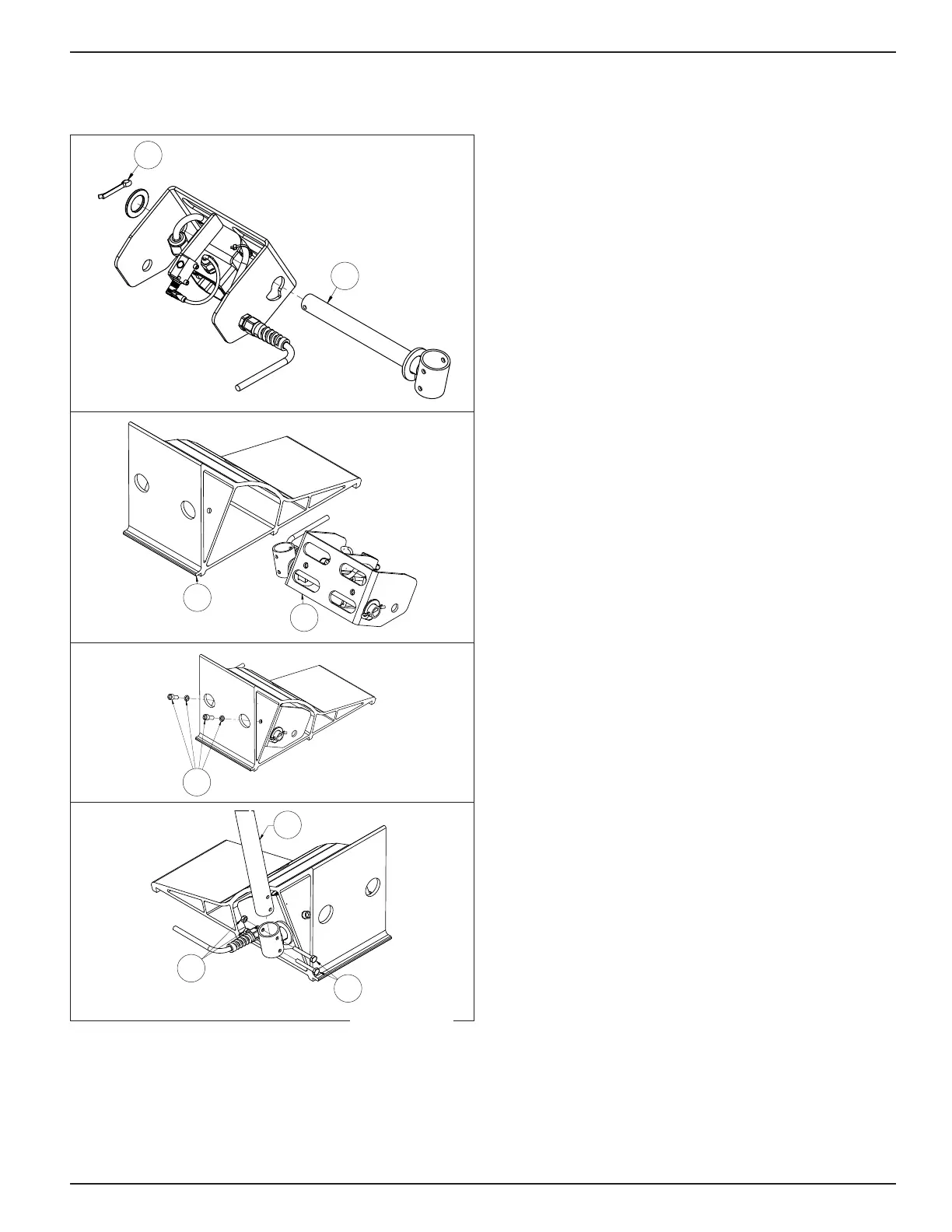

STEP 11

1) REINSTALL GWC MOUNTING BRACKET HARDWARE

STEP 12

1) REINSTALL HANDLE AND HANDLE MOUNTING HARDWARE.

STEP 12 (NOT SHOWN)

1) TEST UNIT FOR PROPER OPERATION.

N

OT

R

EL

EAS

E

D

PRODUCTS CORPORATION.

.060

=

=

PRODUCTS CORPORATION

REV

SHEET

TITLE

SIZE

SCALE

CONFIDENTIAL

®

© 2019 RITE-HITE®

REVISION STATUS

DRAWN BY

RESPONSIBLE ENGINEER

DO NOT SCALE DRA WING

MATERIAL

INSTR MODFY GWC1 BARR ORIENT

C

0159009

--

1:4

DWG NO

.X

B. WIEBERDINK

DIMENSIONS ARE IN INCHES.

THIRD ANGLE PROJECTIO N

ALL SHEETS ARE THE SAME

.XX

TOLERANCES:

A

B

C

D

D

C

B

A

4

3

2

1

4

32

ANGLE

.030

FINISH

6 OF 6

2.0

REFERENCE

.XXX

UNLESS OTHERWISE SPECIFIED

WEIGHT

MANUFACTURING ENGINEER

1

G. PROFFITT

= .12 0

=

THIS DOCUMENT IS THE PROPERTY

OF RITE-HITE® PRODUCTS

CORPORATION SUBJECT MATTER

HEREIN IS CONFIDENTIAL . DO NOT

USE, REPRODUCE, COPY OR

DISCLOSE EXCEPT WITH WRITTEN

CONSENT OF RITE-HITE®

PRODUCTS CORPORATION

STEP 11

GWC BRACKET

MOUNTING HARDWARE

STEP 12

HANDLE MOUNTING

HARDWARE

HANDLE

HANDLE MOUNTING

HARDWARE

REV DATE DESCRIPTION ECN APPROVED BY

A 06/05/2019 RELEASE TO PRODUCTION 20190145 G. PROFFITT

REVISION HISTORY

L

NOTES:

STEP 11

1) REINSTALL GWC MOUNTING BRACKET HARDWARE

STEP 12

1) REINSTALL HANDLE AND HANDLE MOUNTING HARDWARE.

STEP 12 (NOT SHOWN)

1) TEST UNIT FOR PROPER OPERATION.

N

OT

R

EL

EAS

E

D

PRODUCTS CORPORATION.

.060

=

=

PRODUCTS CORPORATION

REV

SHEET

TITLE

SIZE

SCALE

CONFIDENTIAL

®

© 2019 RITE-HITE®

REVISION STATUS

DRAWN BY

RESPONSIBLE ENGINEER

DO NOT SCALE DRAWING

MATERIAL

INSTR MODFY GWC1 BARR ORIENT

C

0159009

--

1:4

DWG NO

.X

B. WIEBERDINK

DIMENSIONS ARE IN INCHE S.

THIRD ANGLE PROJE CTION

ALL SHEETS ARE THE SAME

.XX

TOLERANCES:

A

B

C

D

D

C

B

A

4

3

2

1

4

32

ANGLE

.030

FINISH

6 OF 6

2.0

REFERENCE

.XXX

UNLESS OTHERWISE SPECIFIED

WEIGHT

MANUFACTURING ENGINEER

1

G. PROFFITT

= .120

=

THIS DOCUMENT IS THE PROPERTY

OF RITE-HITE® PRODUCTS

CORPORATION SUBJECT MATTER

HEREIN IS CONFIDENTIAL. DO NOT

USE, REPRODUCE, COPY OR

DISCLOSE EXCEPT WITH WRITTEN

CONSENT OF RITE-HITE®

PRODUCTS CORPORATION

STEP 11

GWC BRACKET

MOUNTING HARDWARE

STEP 12

HANDLE MOUNTING

HARDWARE

HANDLE

HANDLE MOUNTING

HARDWARE

REV DATE DESCRIPTION ECN APPROVED BY

A 06/05/2019 RELEASE TO PRODUCTION 20190145 G. PROFFITT

REVISION HISTORY

M1

M2

M2

6. Reinstall:

• Shaft (J1) and shaft retaining hardware (J2) .

• GWC-1000 assembly (K1) back into chock (K2).

• GWC-1000 mounting bracket hardware (L)

• Handle (M1) and mounting hardware (M2).

7. Test unit for proper operation.

Figure 5

INSTALLATION

Change Orientation Continued

Rite‑Hite

®

Installation/Service/Owner's Manual Genisys™ GWC‑1000 Global Wheel Chock

Publication: AMEN00274 2020-06-26 7

Loading...

Loading...