FS Pag. 36 Rev 00 02/12

UK

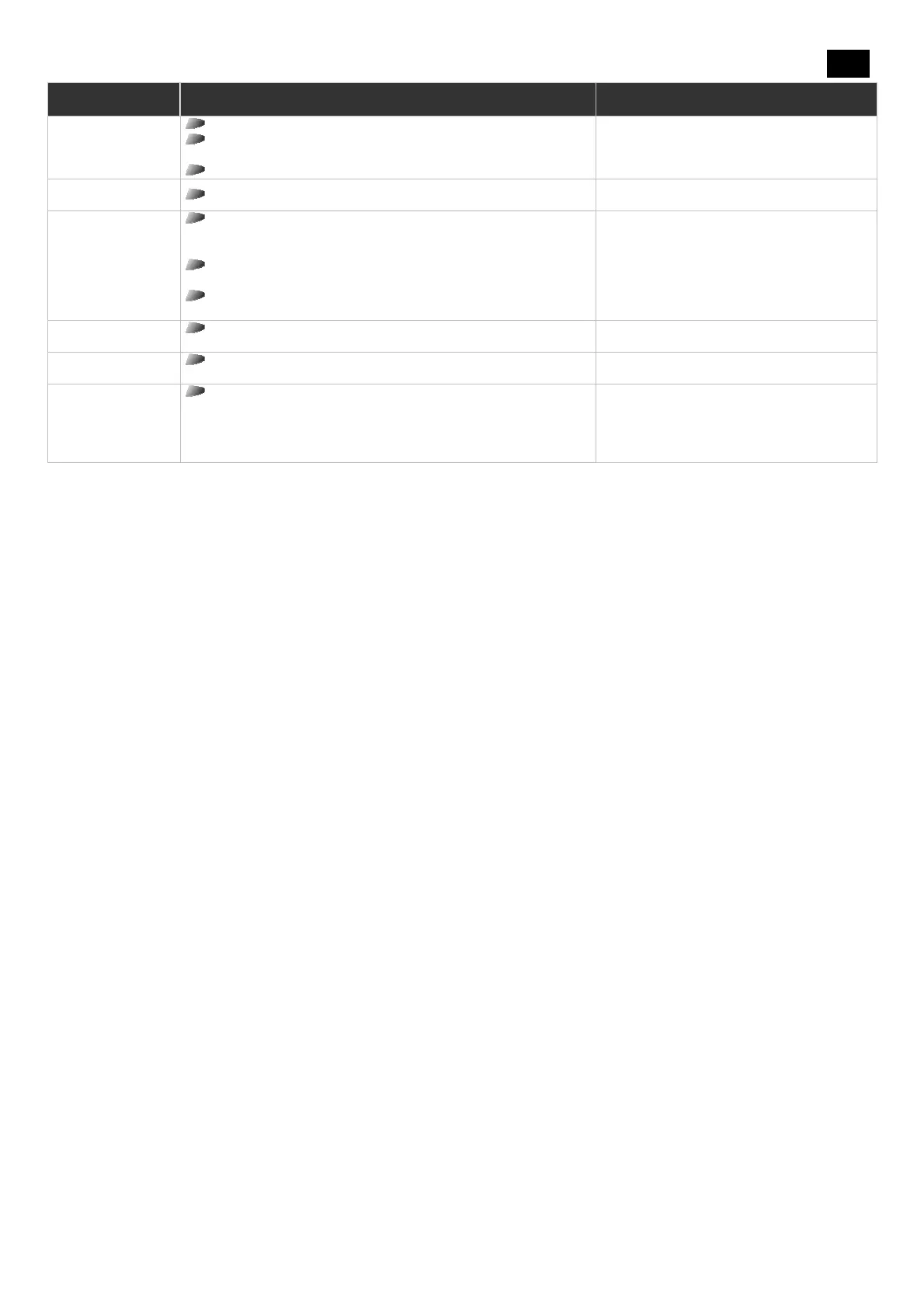

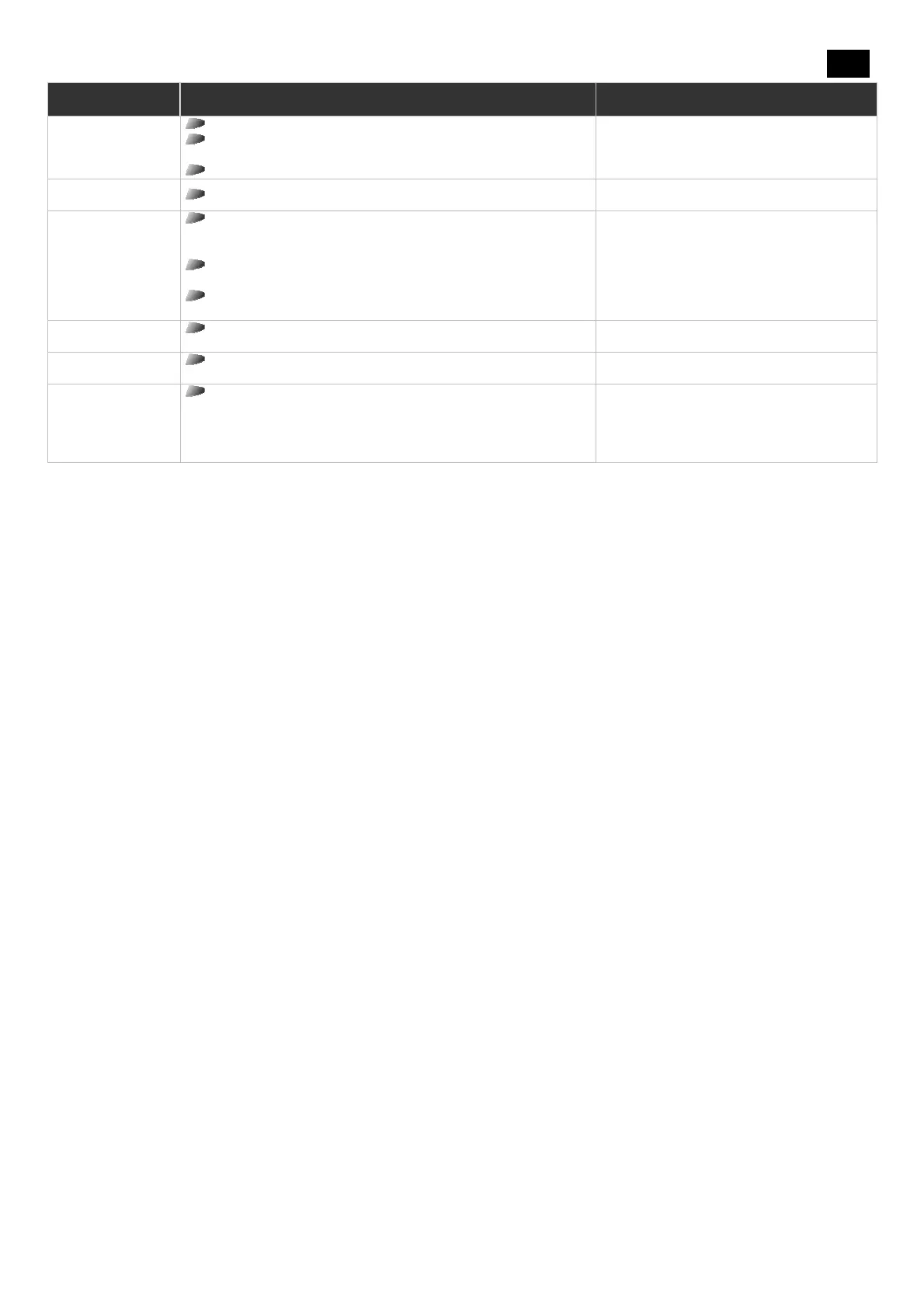

CHAPTER CONTENTS RECIPIENTS

Chapter 4

Transportation and

Installation

Description of the lifting and transportation modes of the MACHINE;

description of the modes of connection to the power supply and of

the appliances;

description of the storage modes of the MACHINE.

All staff using the machine (in particular the

mechanic and electric maintenance workers, the

technicians of the Producer, and the personnel

appointed to handling.)

Chapter 5

Machine use

Description of the procedures to follow in order to use the MACHINE. All staff using the MACHINE.

Chapter 6

Maintenance and

Demolition

Description of the verification and control procedures of the parts

and the components of the

MACHINE (in particular, the parts most

subject to wear out);

description of the procedures that allow the appointed personnel to

perform the cleaning of the

MACHINE;

presentation of the indications to perform the dismantling,

demolition, and disposal of the

MACHINE.

All staff using the machine (in particular the

mechanic and electric maintenance workers, the

technicians of the Producer, and the personnel

appointed to handling.)

Chapter 7 Optional

Description of the possible optional features that can be installed on

the MACHINE.

All staff using the

MACHINE.

Chapter 8 faults

search

List of the possible malfunctions of the machine and the relative

solutions.

All staff using the

MACHINE.

Chapter 9

Attachments

Indications for the retrieval of the:

technical sheet of the

MACHINE,

refrigerant diagram,

electrical wiring diagram of the

MACHINE,

documentation of the components present on the

MACHINE.

All staff using the

MACHINE.

1.4. Convention and Definitions

1.4.1. General Information

The Use and Maintenance Handbook of the MACHINE was divided into chapters to enable, for each phase of the MACHINE life (transport,

installation, use, regulation, maintenance and decommissioning), easy availability of relative necessary information for the user of the

MACHINE.

All the documentation relating to the

MACHINE was drafted by developing the topics indicated by the Machinery Directive

(2006/42/EC), PED Directive (97/23/CE) and the safety norms in force; therefore, the complete reading of all the relative material is

indispensible to obtain the best performance from the

MACHINE and ensure maximum duration of all its units.

The configuration of certain units or devices described or shown in the documents can differ from that in the

MACHINE in the specific

preparation according to particular requirements or safety norms; in this case, certain descriptions, references or procedures

recommended can be generic in order to maintain their efficiency. Drawings mentioned or photographs are provided for example

purposes as a reference for easy comprehension of the text.

1.4.2. Term conventions

MACHINE: the term used in this Use and Maintenance Handbook to indicate the BLOCKSYSTEM SERIES FS.

IPD: the acronym indicates Individual Protection Device/s.

1.4.3. Definitions

DANGER ZONE

Any ZONE inside or near the MACHINE in which the presence of an exposed person composes a risk to the safety and health of that

person.

USER

Any

PERSON (business person/company) adequately using the MACHINE or that assigns its use or operations connected to use to trained

people.

EXPOSED PERSON

Any PERSON located inside or partly in the danger zone or near these zones.

OPERATOR

Staff, generally without specific skills, that conduct the operations necessary to operate the

MACHINE and clean the MACHINE and the

place in which it is installed; if necessary, the operator can conduct simple regulation and restore of functioning operations on the

MACHINE.

MECHANICAL MAINTENANCE PERSON

Q

UALIFIED TECHNICIAN who can intervene on any mechanical unit to regulate or repair it and conduct the necessary maintenance

operations.

The mechanical maintenance person is not enabled to conduct intervention on the electrical systems when voltage is present.

ELECTRICAL MAINTENANCE PERSON

Q

UALIFIED TECHNICIAN responsible for all electrical intervention (regulation, maintenance and repairs) and, when necessary, works with

voltage present inside the electrical cabinets and the shunt boxes.

MOVEMENT STAFF

Q

UALIFIED STAFF that perform the tasks of moving the MACHINE or the materials used if the operation requires the use of lifting devices.

MANUFACTURER TECHNICIAN

QUALIFIED TECHNICIAN made available by the manufacturer of the MACHINE to conduct complex operations in particular situations or,

however, when agreed with the user.

Loading...

Loading...