FS Pag. 60 Rev 00 02/12

UK

TELEMANAGEMENT SYSTEM

Enables monitoring and programming of the Blocksystem FS via a PC or data recorder. It gives the possibility of advanced

management (communication via modem or GSM) of all the Blocksystem FS alarms.

8

8

.

.

F

F

a

a

u

u

l

l

t

t

s

s

s

s

e

e

a

a

r

r

c

c

h

h

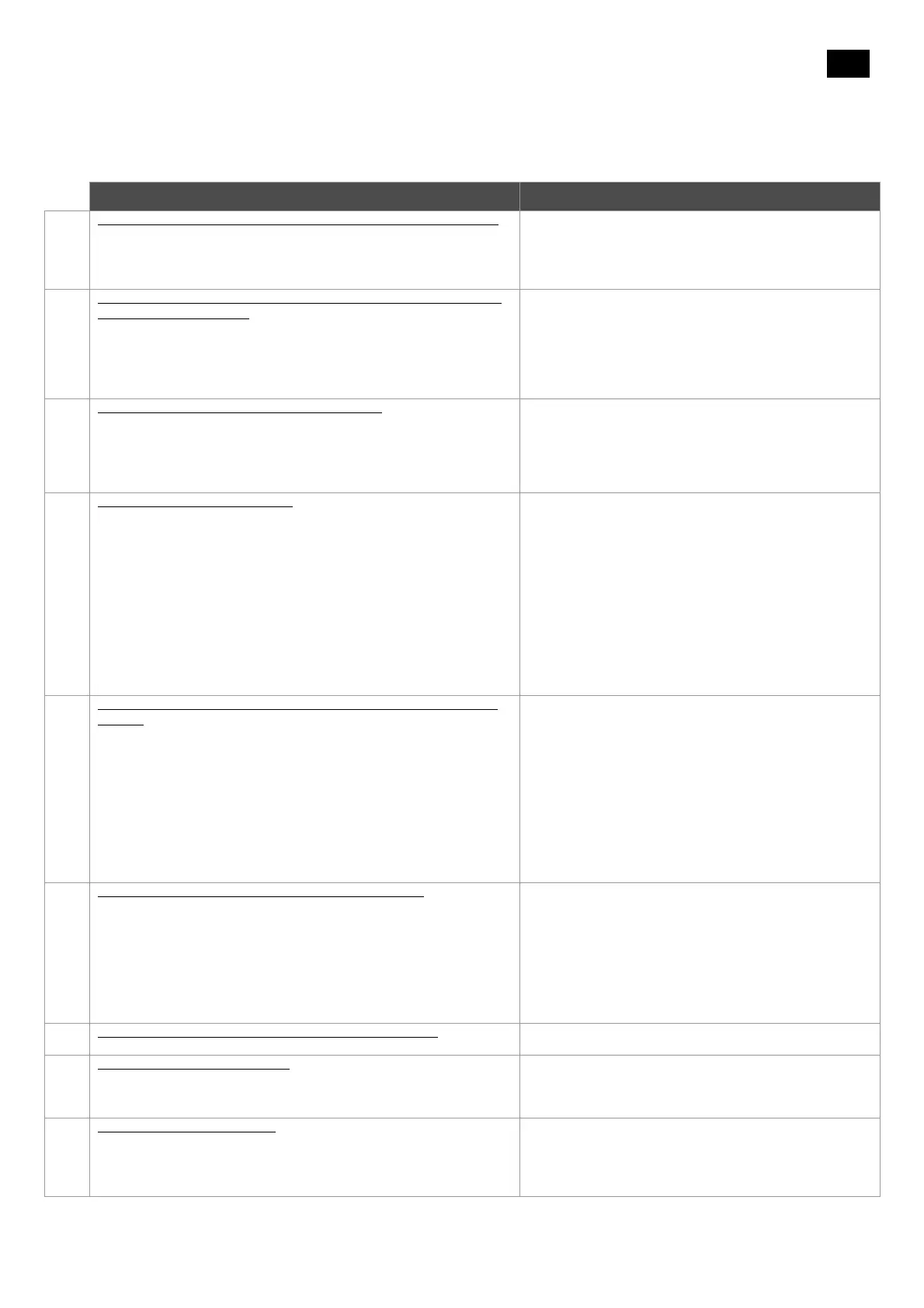

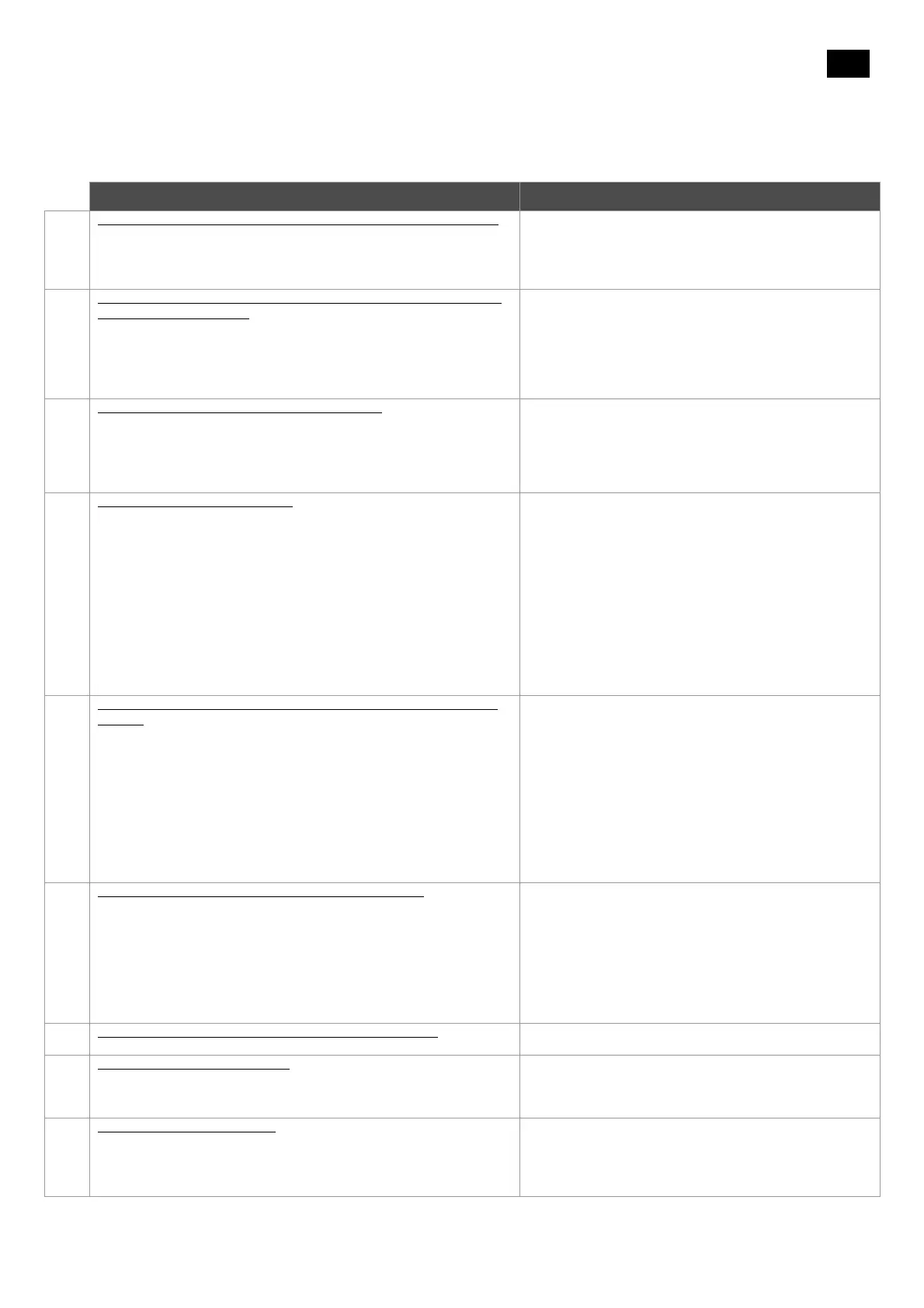

POSSIBLE CAUSES SOLUTIONS

A

The compressor does not start up and does not release a humming sound

1 Lack of voltage. Start-up relay with open contacts.

2 Thermal protector is intervening.

3 Loose electrical connections or wrong electrical connections.

1 Check the supply line or substitute the relay.

2 Check the electrical connections.

3 Tighten the connections or carry them out again in

compliance to the electrical wiring diagram.

B

The compressor does not start up (but releases a humming sound) and the

thermal protector intervenes

1 Wrong electrical connections.

2 Low voltage supply to the compressor.

3 Faulty start-up of the condenser.

4 The relay doesn’t close.

5 The winding on the electrical motor is interrupted or in short circuit.

1 Re-do the connections.

2 Identify the cause and eliminate it.

3 Identify the cause and replace the condenser.

4 Identify the cause and substitute the relay if necessary.

5 Substitute the compressor.

C

The compressor starts up, but the relay doesn’t open

1 Wrong electrical connections.

2 Low voltage supply to the compressor.

3 Relay blocked in closure.

4 Excessive discharge pressure.

5 The winding on the electrical motor is interrupted or in short circuit.

1 Check the electrical circuit.

2 Identify the cause and eliminate it.

3 Identify the cause and eliminate it.

4 Identify the cause and substitute the relay if necessary.

5 Replace the compressor.

D

Intervention of the thermal protector

1 Low voltage supply to the compressor (unbalanced phases on the tri-

phase motors).

2 Defective thermal protector.

3 Defective electric-run condenser.

4 Excessive discharge pressure.

5 High suction pressure.

6 Overheated compressor, hot return gas.

7 Winding of the compressor motor in short circuit.

1 Identify the cause and eliminate it.

2 Check its characteristics and replace it if necessary.

3 Identify the cause and eliminate it.

4 Check the ventilation and any potential restrictions or

obstructions in the system circuit.

5 Check the sizing of the system. Replace the condensing

unit with a more powerful one, if necessary.

6 Check the refrigerant load; if need be, repair the loss

and add gas if necessary till the charge stated in the

label.

7 Replace the compressor.

E

The compressor starts up and circulates, the functioning cycles are of brief

duration

1 Thermal protector.

2 Thermostat.

3 Intervention of the high pressure switch, due to the insufficient cooling

of the condenser.

4 Intervention of the high pressure switch, due to the excessive load

of refrigerant gas.

5 Intervention of the low pressure switch, due to the scarce load of

refrigerant gas.

6 Intervention of the low pressure switch, due to the restriction or

clogging of the expansion valve.

1 See previous point (thermal protector intervention).

2 Small differential; correct the regulation.

3 Check the correct functioning of the motor fan or clean

the condenser.

4 Reduce the load of refrigerant gas.

5 Repair the loss and add refrigerant gas.

6 Replace the expansion valve.

F

The compressor operates uninterruptedly or for long periods

1 Scarce load of refrigerant gas.

2 Thermostat with contacts locked in closure.

3 System not sufficiently sized in function of the load.

4 Excessive load to cool or insufficient insulation.

5 Evaporator covered with ice.

6 Restriction in the system circuit.

7 Clogged condenser.

1 Repair the loss and add refrigerant gas till the charge

stated in the label.

2 Replace the thermostat.

3 Replace the system with a more powerful one.

4 Reduce the load and improve insulation, if possible.

5 Perform defrosting till the charge stated in the label .

6 Identify the resistance and eliminate it.

7 Clean the condenser.

G

Electric-run condenser damaged, interrupted, or in short circuit

1 Wrong electric-run condenser.

1 Replace the condenser with the correct type.

H

Start-up relay defective or burnt out

1 Wrong relay.

2 Relay mounted in the incorrect position.

3 Wrong lectric-run condenser.

1 Replace the relay with the correct one.

2 Re-assemble the relay in the correct position.

3 Replace the condenser with the correct type.

I

Cold-room temperature too high

1 Thermostat regulated too high.

2 Undersized expansion valve.

3 Undersized evaporator.

4 Insufficient air circulation.

1 Regulate it correctly.

2 Replace the expansion valve with a suitable one.

3 Replace it, increasing the surface of the evaporator.

4 Improve air circulation,

Loading...

Loading...