Open the startup valve.

The startup valve is used to achieve safe pressure compensation at the throttle

diaphragm.

2.1.1 Commissioning

Close outlet gate valve

Fully release the setpoint springs of the regulator RMG 630/640 in the regualting stage

and the load limiting stage (regulator RMG 630 only) by turning the setpoint adjustment

screw anti-clockwise.

Apply inlet pressure slowly.

The startup valve must always be closed again.

Adjust the setpoint value in the load limiting stage at the regulator RMG 630 to

approx. 10 bar above p

a

.

Adjust the output pressure in small steps by turning the setpoint adjustment screw

clockwise until the desired value has been reached. The load limiting pressure at the

RMG 630 will rise automatically.

2.1.2. De-commissioning

Turn the setpoint adjustment screw of the regulating stage anti-clockwise

Slowly close the outlet gate valve

2.2 Special maintenance notices

Due to the maintenance-friendly design the maintenance of the gas pressure regulator is principally limited

to checking the throttle diaphragm. This must be checked for wear and swelling and where necessary be renewed.

Prior to dismantling all gas supplied chambers must be depressurised.

The throttle diaphragm (306) must be inserted into the main valve body without

distortion.

Foam rings (314 and 319) from nominal width DN 80/150 are to be renewed with

every maintenance.

2.2.1 Screw tightening torques M

A

in Nm

screw

item no. 25/50 50/100 80/150 100/200

318 160 160 240 240

nominal width DN

components lubricants RMG part no.

all O rings and

diaphram tensioning bead silicon grease 00 027 081 (tube 0.1 kg)

all fastening screws

and pipe screw connections assembly grease 00 028 267

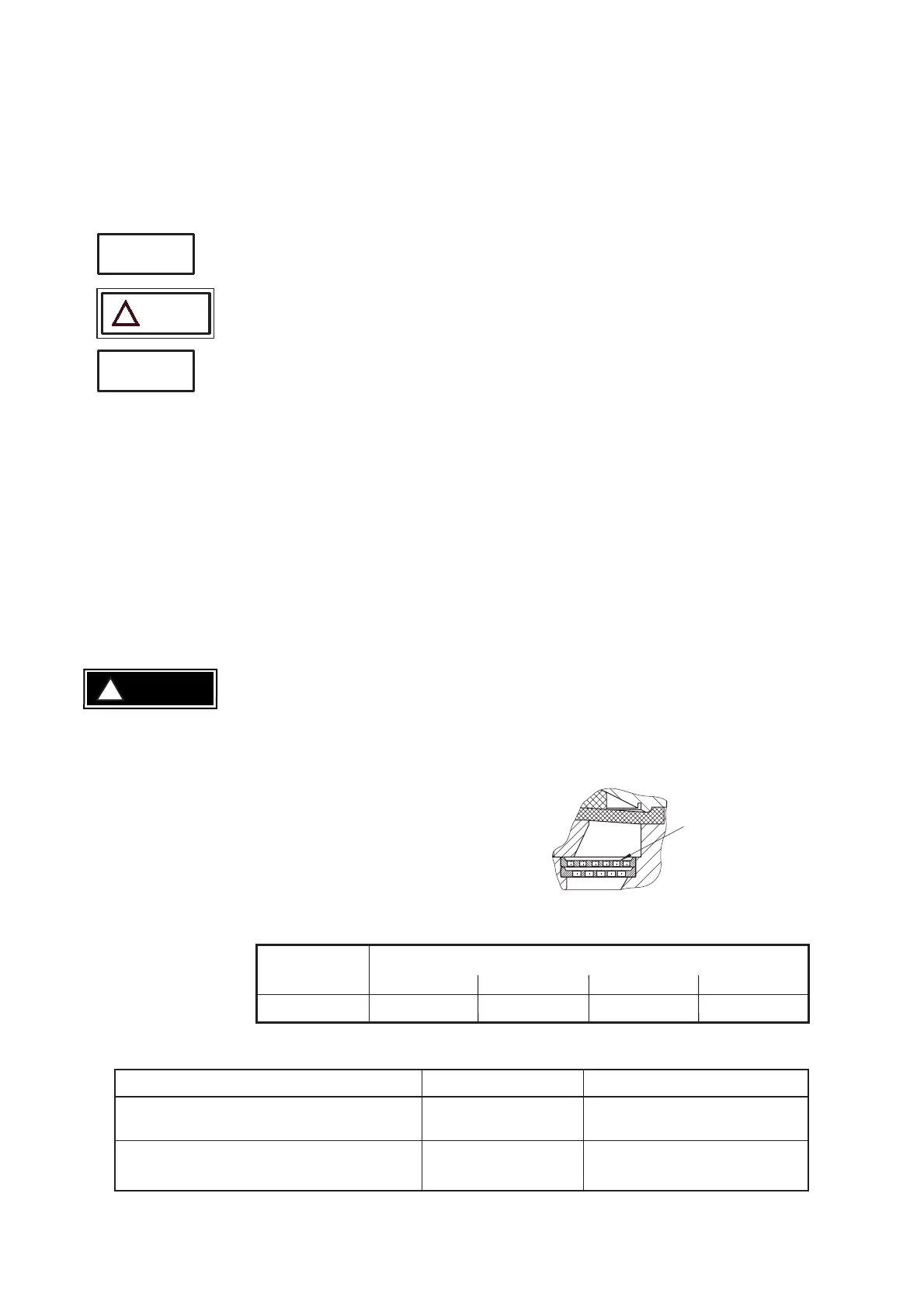

For designs with noise reduction

the correct position of the relief plates

(328) must be observed ->

The groove of the relief plates

must face upwards

503.20 p.04

2. Gas pressure regulator

2.1 Special operating notices

•

•

•

Caution

!

•

•

•

•

•

•

2.2.2

Lubricants

•

•

•

!

Danger

Loading...

Loading...