..

7.

MAGNETO

.

,

.

7-1

'

MAGNETO

._

.

.'

".

,

r

The spark for ignition is furnished by a magneto assembly. The magneto consists of a flywheel, ignition coil and breaker

'

assembly .(.including condenser),

of

which flywheel is 'mounted on. crankshaft and ignition coil and breaker assembly are

mounted

.-

in crankcase directly.

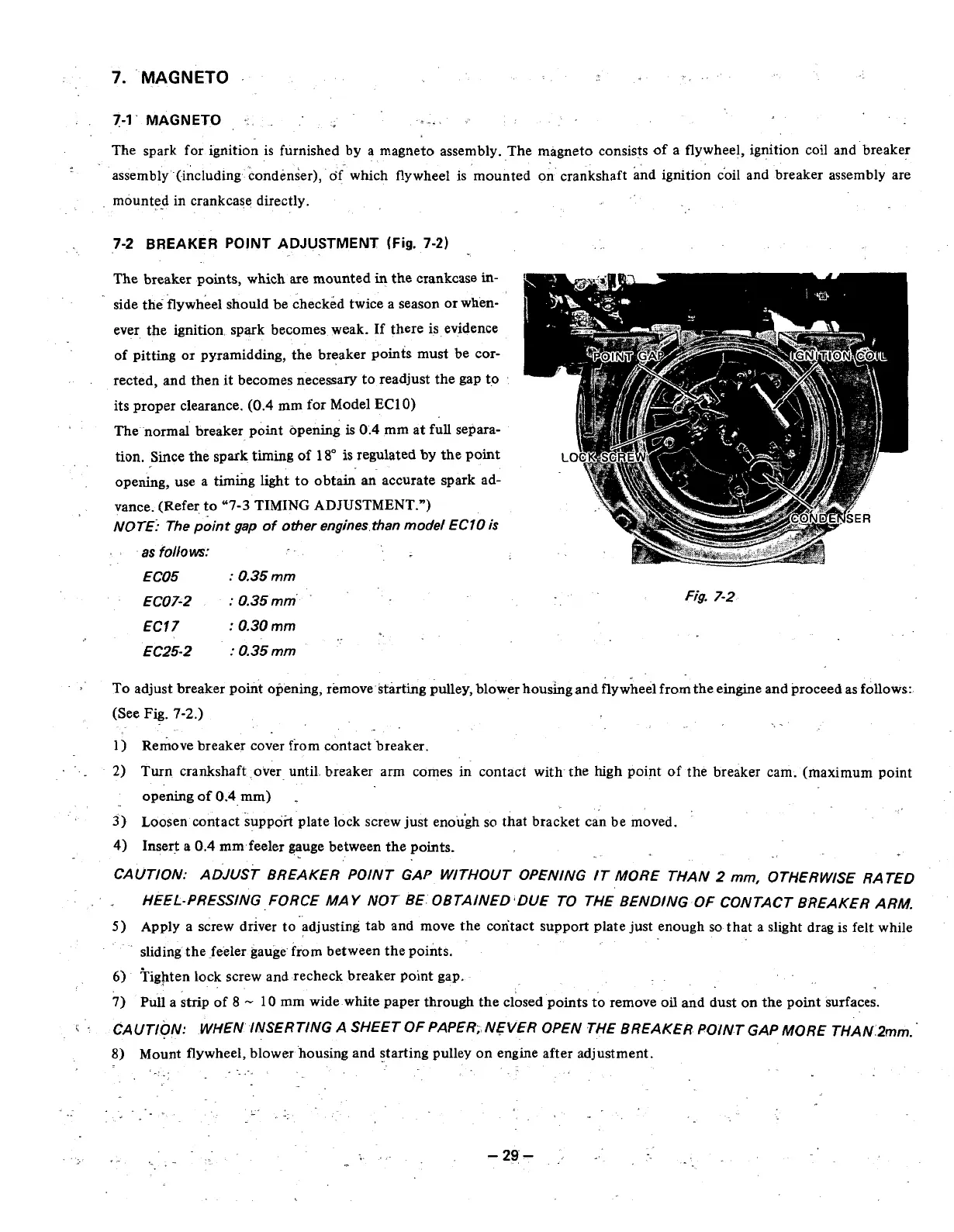

7-2

BREAKER

POINT

ADJUSTMENT

(Fig.

7-2)

The breaker points, which are mounted

in

the crankcase in-

side the flywheel should be checked twice a season

or

when-

ever the ignition, spark becomes weak. If there is,evidence

of

pitting or pyramidding, the breaker points must be cor-

rected, and then it becomes necessary to readjust the gap to

its proper clearance.

(0.4

mm

for Model EC10)

The normal breaker point opening is

0.4

mm at full separa-

tion. Since the spark timing

of

18"

is

regulated by the

point

opening, use a timihg light to obtain

an

accurate spark ad-

vance. (Refer to

"7-3

TIMING

ADJUSTMENT.")

NOTEI The point gap

of

other engines.than model EC70 is

as

follows:

EC05

:

0.35

mm

EC07-2

:

0.35mm'

ECl7

:

0.30

mm

EC25-2

:

0.35mm

I.

Ftg.

7-2

i'

To adjust breaker poixit opening, remove starting pulley, blower houshg and flywheel from the eingine and proceed as follows:

1-

(See

Fig.

7-2.)

1)

Remove breaker cover from contact breaker.

2)

Turn

crankshaft .over until. breaker arm comes in contact with. the high point

of

the breaker cam. (maximum point

',

.

opening of

0.4

mm)

3)

Loosen contact suppoit plate lock screw just enough

so

that bracket can be moved.

4)

Insert

a

0.4

mm feeler gauge between the points.

CAUTION:

ADJUS?

BREAKER POINT GAP WITHOUT OPENING

IT

MORE THAN

2

mm,

OTHERWISE RATED

,-

HEEL-PRESSING FORCE MAY

NOT

BE: OBTAINED 'DUE

TO

THE BENDING

Of

CONTACT BREAKER

ARM.

5)

Apply a screw driver to.adjusting tab and move the contact support plate just enough

so

that a slight drag is felt while

sliding the feeler gauge from between the points.

6)

kghten lock screw and recheck breaker point gap.

..

7)

Pull a strip of

8

-

10

mm wide white paper through the closed points

to

remove

oil

and dust on the point surfaces.

I.

.

'

CAUTION: WHEN INSERTING

A

SHEET

OF

PAPER;, NEVER OPEN THE BREAKER POINT GAP MORE THAN:2mm.'

8)

Mount flywheel, blower housing and starting pulley on engine after adjustment.

-. .

..

~

...

,.

..

..

VI

..

.

_..

Loading...

Loading...