8.

TROUBLE

SHOOTING

For a gasoline engine to start and run satisfactorily, the following three requirements must be met:

1) The cylinder filled with a proper fuel-air mixture.

2)

An appropriate compression in the cylinder.

3)

Good spark at correct time

to

ignite the mixture.

If all the three requirements are not met simultaneously, an engine can not be started. There are also other factors

such

as

heavy load at starting and

too

long an exhaust pipe causing a high back pressure, which contribute to hard starting. The

most

common causes

of

engine troubles are given below.

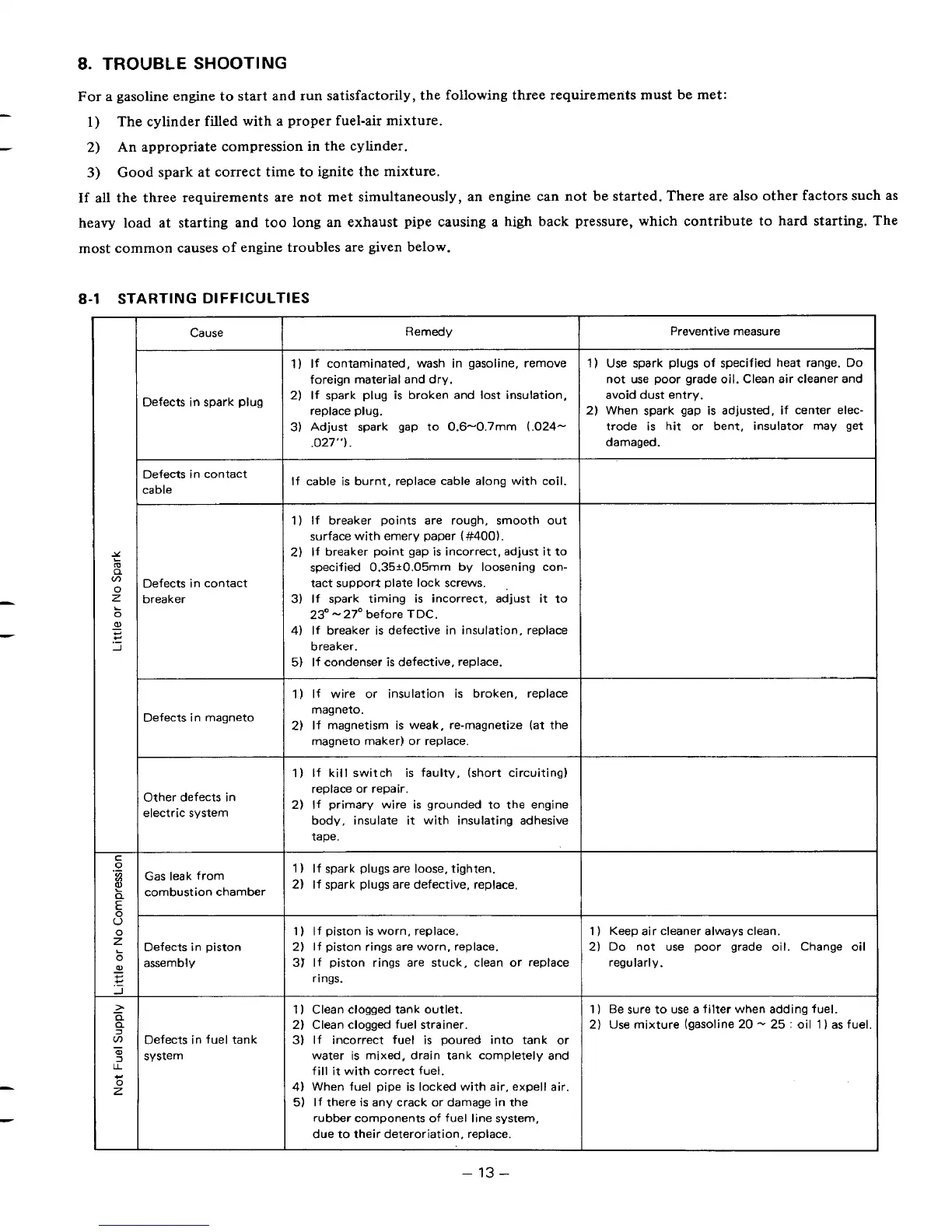

8-1

STARTING

DIFFICULTIES

Cause

Defects

in

spark

plug

Defects in contact

cable

Defects in contact

breaker

Defects in magneto

Other defects in

electric system

Gas leak from

combustion chamber

Defects in piston

assembly

Defects in fuel tank

system

Remedy

1)

If

contaminated, wash in gasoline, remove

2)

If spark plug

is

broken and lost insulation,

3) Adjust spark gap to 0.6-0.7mm

(.024-

foreign material and dry.

replace plug.

,027").

If cable is burnt, replace cable along with coil.

1)

If breaker points are rough, smooth out

surface with emery paper

(#400).

2)

If breaker point gap

is

incorrect,

adjust

it

to

specified 0.35t0.05mm by loosening con-

tact support plate lock screws.

3)

If

spark timing is incorrect, adjust

it

to

23"

-

27'

before TDC.

4)

If breaker is defective in insulation, replace

breaker.

5)

If

condenser

is

defective, replace.

1)

If wire or insulation

is

broken, replace

2)

If

magnetism

is

weak, re-magnetize (at the

magneto.

magneto maker)

or

replace.

1)

If kill switch

is

faulty, (short circuiting)

replace or repair.

2)

If primary wire

is

grounded

to

the engine

body, insulate

it

with insulating adhesive

tape.

1)

If spark plugs are

loose,

tighten.

2)

If

spark plugs are defective, replace.

1)

If

piston

is

worn, replace.

2)

If

piston rings are worn, replace.

31

If piston rings are stuck, clean or replace

rings.

1)

Clean clogged tank outlet.

2)

Clean clogged fuel strainer.

3)

If incorrect fuel

is

poured into tank or

water is mixed, drain tank completely and

fill

it

with correct fuel.

4)

When fuel pipe is locked with

air,

expel1 air.

5)

If

there

is

any crack or damage in the

rubber components of fuel line system,

due

to

their deteroriation, replace.

-

13

-

Preventive measure

1)

Use spark plugs

of

specified heat range. Do

not

use

poor grade oil. Clean air cleaner and

avoid dust entry.

2)

When spark gap is adjusted, if center elec-

trode

is

hit or bent, insulator may

get

damaged.

1

)

Keep air cleaner always clean.

2)

Do

not use poor grade oil. Change oil

regularly.

1)

Be sure

to

use

a

filter when adding fuel.

2)

Use mixture (gasoline

20

-

25

:

oil

1

I

as fuel

Loading...

Loading...