9.

CHECKS

and

CORRECTIONS

/"

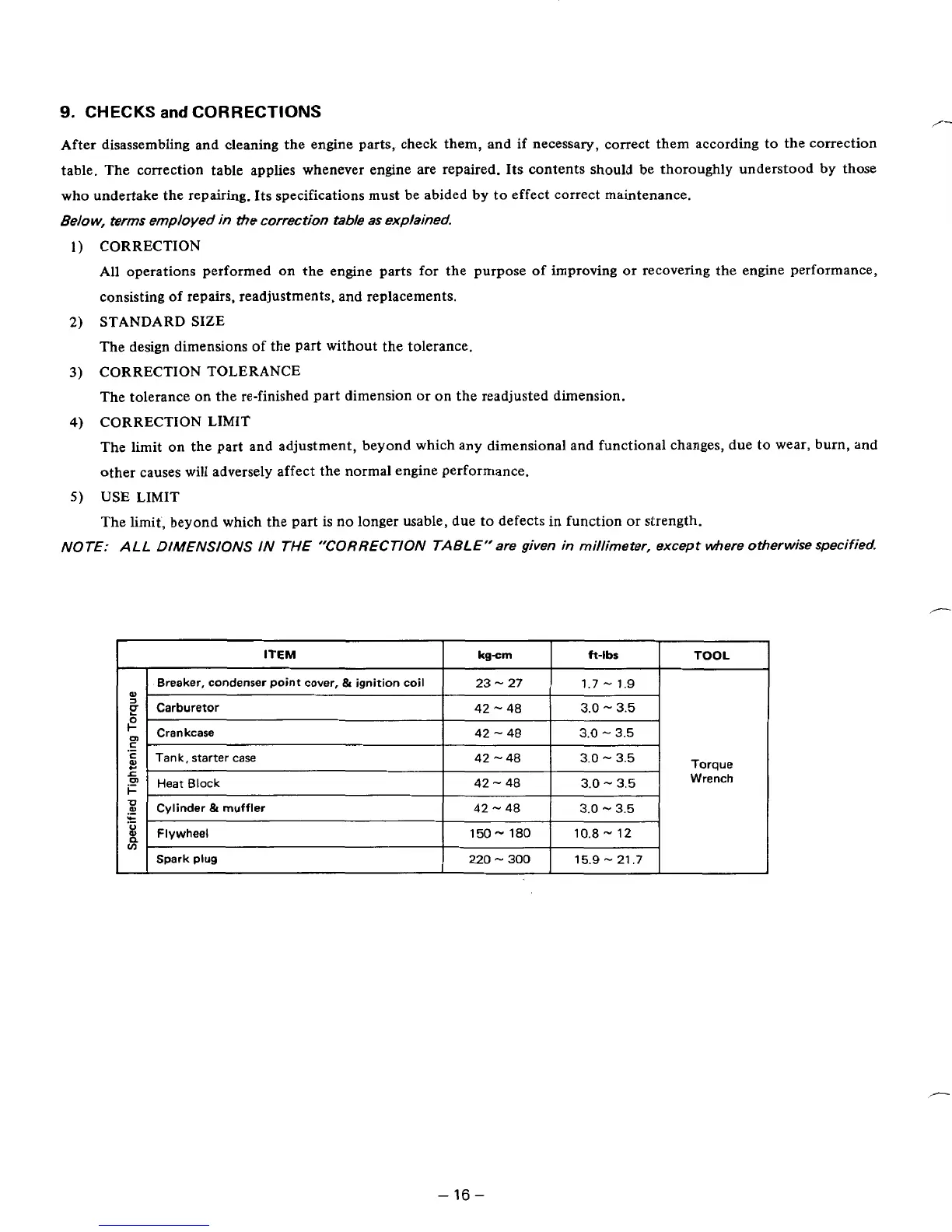

After disassembling and cleaning the engine parts, check them, and if necessary, correct them according to the correction

table. The correction table applies whenever engine are repaired. Its contents should be thoroughly understood by those

who undertake the repairing. Its specifications must be abided by to effect correct maintenance.

Below, terms employed in the correcrion table as explained.

1)

CORRECTION

All operations performed on the engine parts for the purpose

of

improving or recovering the engine performance,

consisting

of

repairs, readjustments, and replacements.

2)

STANDARD

SIZE

The design dimensions of the part without the tolerance.

3)

CORRECTION TOLERANCE

The tolerance on the re-finished part dimension or

on

the readjusted dimension.

4)

CORRECTION LIMIT

The limit on the part and adjustment, beyond which any dimensional and functional changes, due

to

wear, burn, and

other causes will adversely affect the normal engine performance.

5)

USE

LIMIT

The limit, beyond which the part is no longer usable, due to defects in function or strength.

NOT€:

ALL

DlMENSlONS IN

THE

'%ORRECTION

TABL€"are given in millimeter, except where otherwise specified.

,"--

ITEM

TOOL

ft-lbS

kg-crn

Breaker, condenser point cover,

&

ignition coil

3.0

-

3.5

42

-

48 Crankcase

3.0

-

3.5

42

-

48

Carburetor

1.7

-

1.9

23

-

27

E

Tank, starter

case

42

-

48

3.0

-

3.5

2

3.0

-

3.5

I-

42

-

48

Heat

Block

10.8

-

12

150

-

180

Flywheel

g

'c

3.0

-

3.5

42

-

48 Cylinder

&

muffler

2

.-

0.

g

.-

c-

c

Wrench

Torque

r

0

v)

Spark plug

15.9

-

21.7

220

-

300

-

16-

Loading...

Loading...