9-2-4

MAIN

SYSTEM

1)

Remove main jet holder

(9)

and dismount

2)

Remove main

jet

(8)

from main jet holder

'3)

Remove main nozzle

(2)

from carburetor

4)

Reassembly

float chamber-bowl

(6).

(9).

body.

a.

Tighten main jet securely to main jet

holder.

If

not tightened securely an

engine disorder may result through a

too rich

fuel

mixture.

b.

Tighten main jet holder to

90

kg-cm

(6.5

ft.

lbs)

torque.

9-2-5

FLOAT SYSTEM

1)

Extract float

pin

(5)

and remove float

(4)

2)

Reassembly

and needle valve

(14).

Whenever needle valve

is

replaced, re-

place valve seat as well, installing a

matching needle valve and seat assembly.

CAUTION: NEVER USE A DRILL OR A

METAL WIRE

TO

CLEAN JETS. THEY

ARE LIABLE

TO

DAMAGE

THE ORIFICE

AND CAUSE AN ENGINE MALFUNC-

TION. BLOW AIR

TO

CLEAN THEM.

23

17

rn

18

12

11

7

10

13

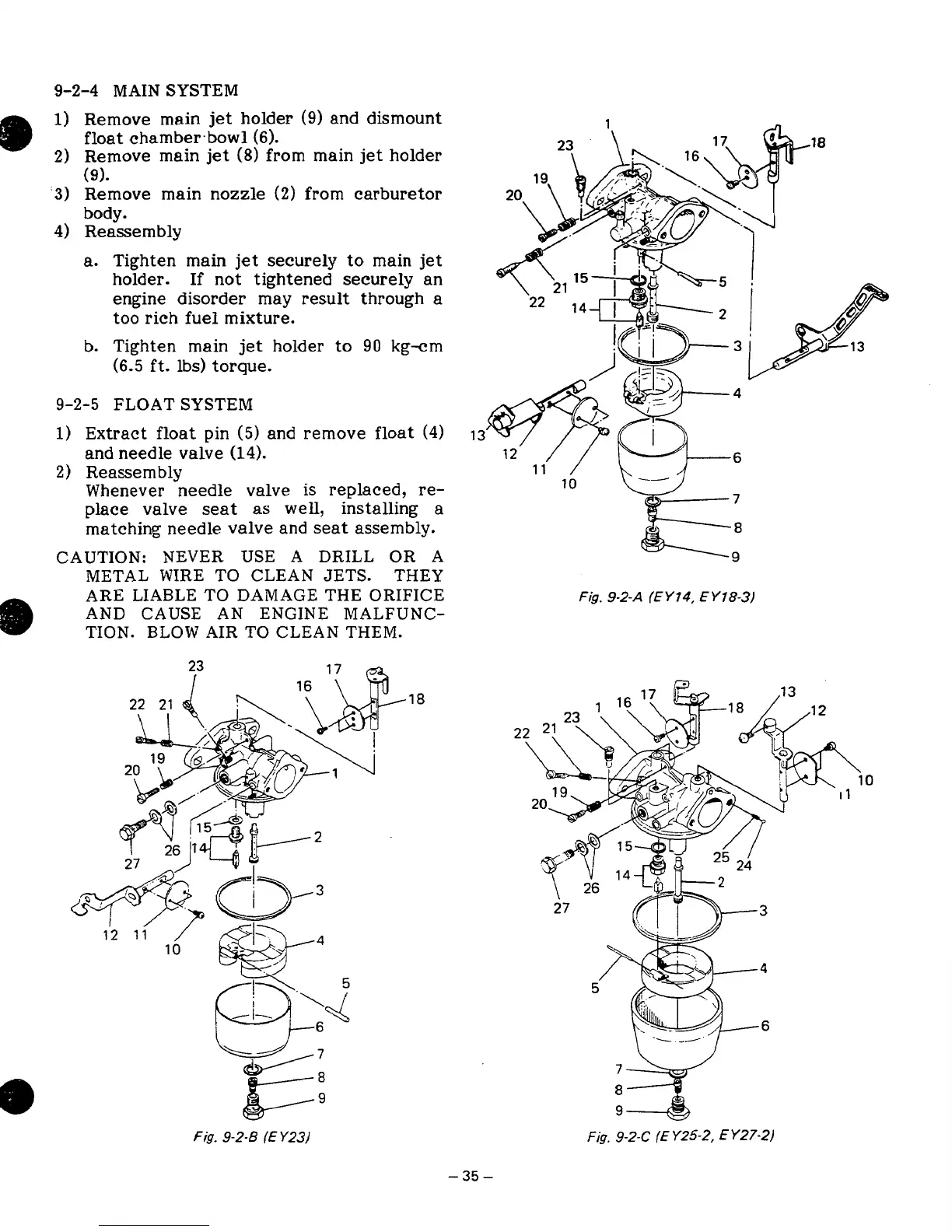

Fig.

9-2-A

(EY74, EY18-31

7

8

9

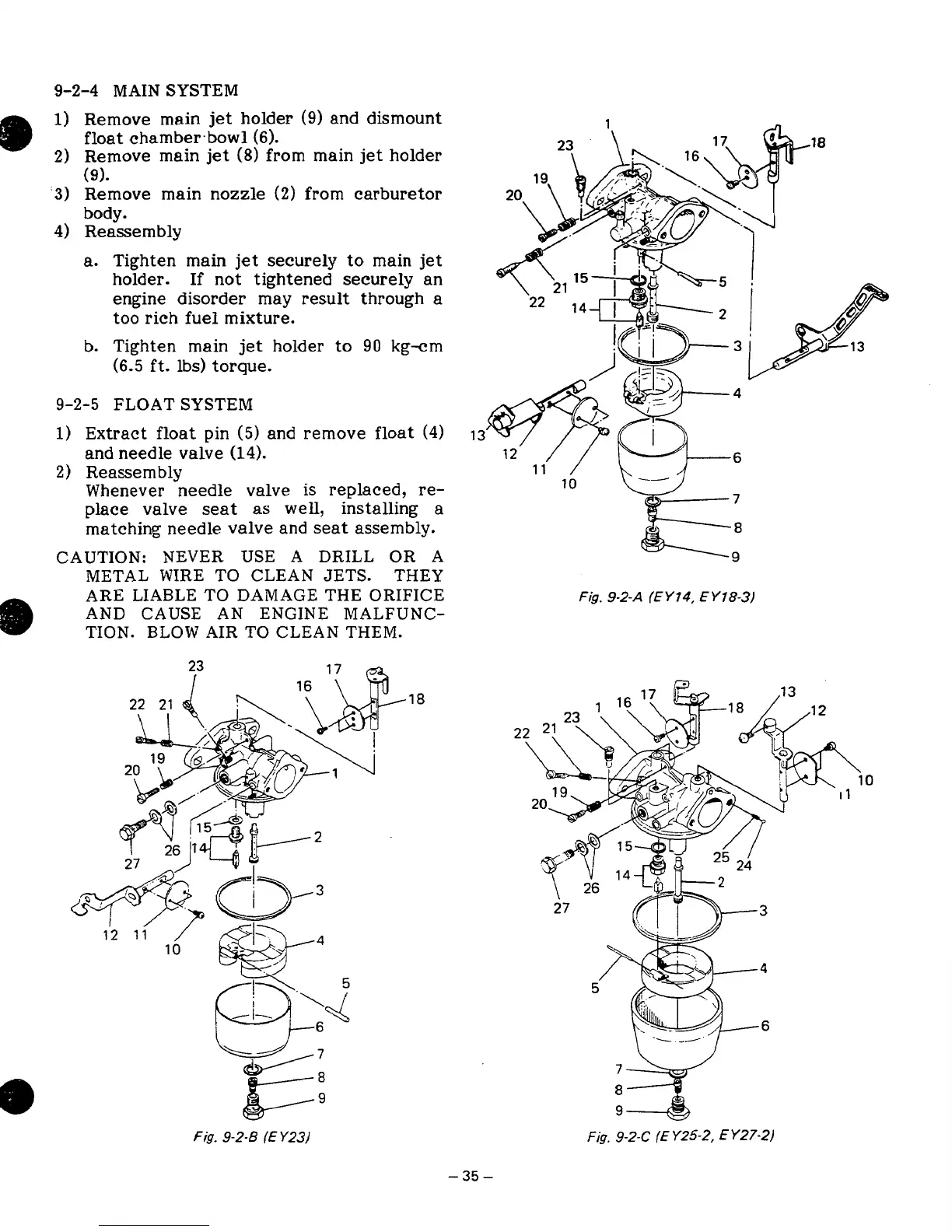

Fig.

9-2-C

(E Y25-2,

EY27-21

Fig.

9-2-6

(E

Y23/

-35

-

Loading...

Loading...