4)

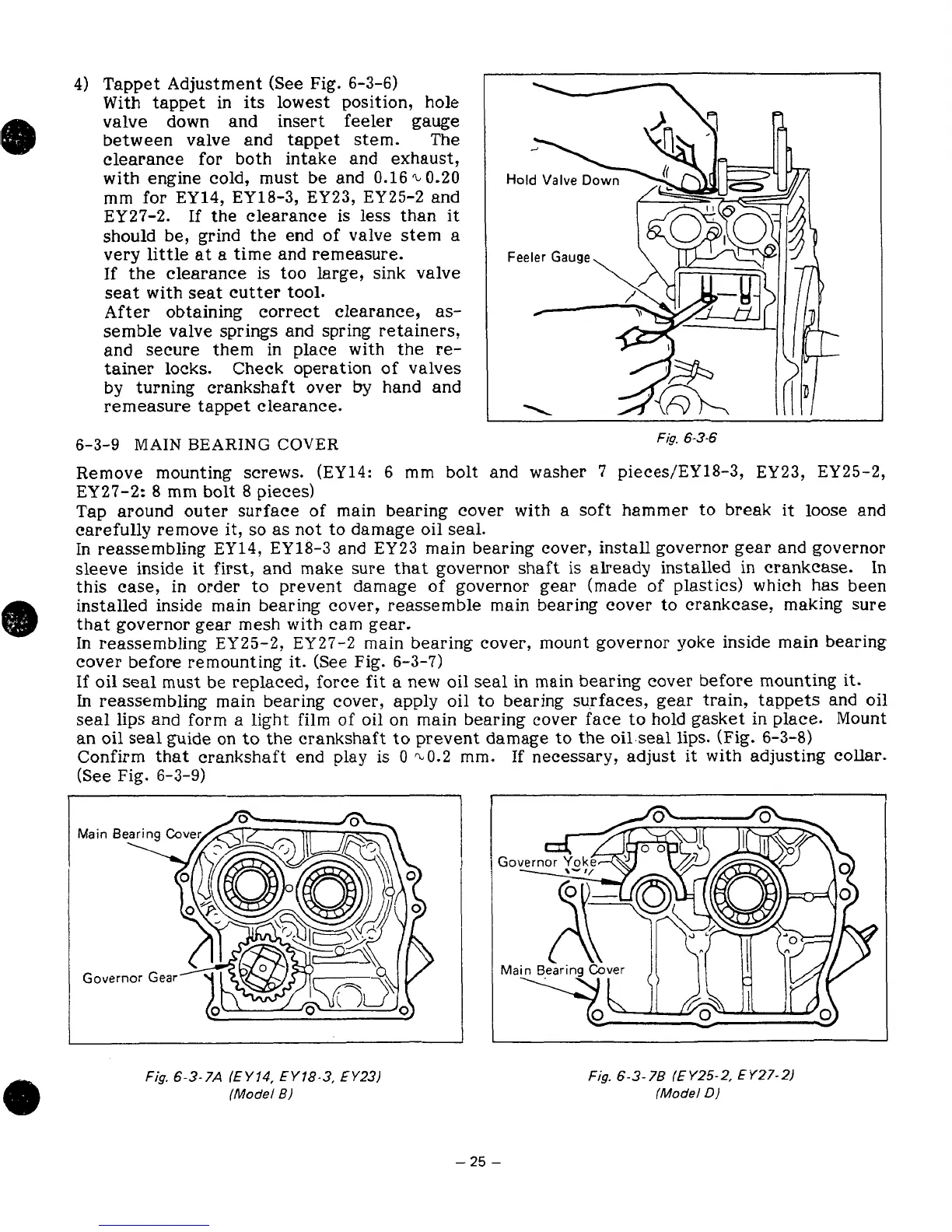

Tappet Adjustment (See Fig.

6-3-6)

With tappet

in

its lowest position, hole

valve down and insert feeler gauge

between valve and tappet stem. The

clearance

for

both intake and exhaust,

with engine cold, must be and

0.16

%

0.20

mm

for

EY14,

EY18-3,

EY23, EY25-2

and

EY27-2.

If

the clearance is less than it

should be, grind the end

of

valve stem a

very little at a time and remeasure.

If

the clearance

is

too large, sink valve

seat with seat cutter tool.

After obtaining correct clearance, as-

semble valve springs and spring retainers,

and

secure them

in

place with the re-

tainer

locks.

Check

operation

of

valves

by

turning crankshaft over

by

hand and

remeasure tappet clearance.

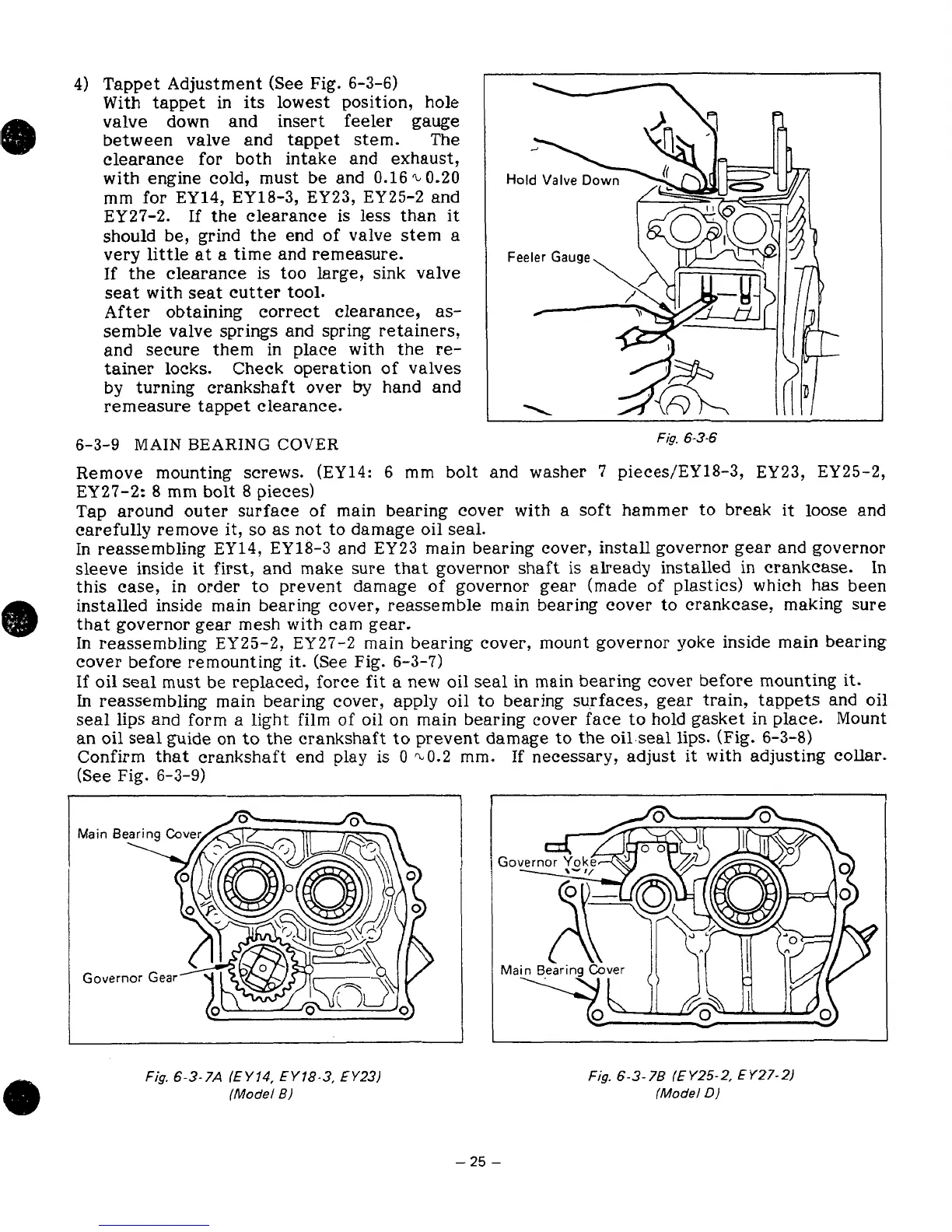

6-3-9

MAIN BEARING COVER

Fig.

6-3-6

Remove mounting screws.

(EY14:

6

mm

bolt and washer

7

pieces/EY18-3,

EY23, EY25-2,

EY27-2:

8

mm

bolt

8

pieces)

Tap around outer surface

of

main bearing cover with a soft hammer to break it loose and

carefully remove it,

so

as not to damage oil seal.

In

reassembling

EY14,

EY18-3

and

EY23

main bearing cover, install governor gear and governor

sleeve inside it

first,

and make sure that governor shaft is already installed in crankcase.

In

this case,

in

order to prevent damage

of

governor gear (made

of

plastics) which has been

installed inside main bearing cover, reassemble main bearing cover to crankcase, making sure

that governor gear mesh

with

cam gear.

In

reassembling

EY25-2,

EY27-2

main bearing cover, mount governor yoke inside main bearing

cover before remounting it. (See Fig.

6-3-7)

If

oil seal must

be

replaced, force fit

a

new

oil seal

in

main bearing cover before mounting it.

In

reassembling main bearing cover, apply oil to bearing surfaces, gear train, tappets and oil

seal lips and form a light film

of

oil

on

main bearing cover face to hold gasket in place. Mount

an

oil

seal guide

on

to the crankshaft to prevent damage to the oil.seal lips. (Fig.

6-3-8)

Confirm that crankshaft end play is

0

~0.2

mm.

If

necessary, adjust it with adjusting collar.

(See

Fig.

6-3-9)

Fig.

6-3-7A

(EY14, EY18-3, EY231

(Model

Bl

Fig.

6-3-

7B

(E

Y25-2,

E

Y27-21

(Model

D)

-

25

-

Loading...

Loading...