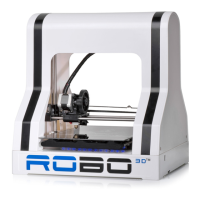

Do you have a question about the Robo 3D R1 and is the answer not in the manual?

| Filament Diameter | 1.75 mm |

|---|---|

| Nozzle Diameter | 0.4 mm |

| Print Speed | Up to 150 mm/s |

| Connectivity | USB, SD card |

| Frame Material | Aluminum |

| Print Technology | Fused Deposition Modeling (FDM) |

| Power Requirements | 110-240V, 50-60Hz |

| Supported Materials | PLA, ABS, Nylon |

| Operating System Compatibility | Windows, Mac |

| Layer Resolution | 100 - 300 microns |

Steps to install the ROBO 3D Printer software by MatterHackers.

Steps to physically connect the ROBO 3D printer to power and computer.

Guide to adding the ROBO 3D printer within the MatterControl software.

Instructions for installing the communication driver for the printer.

Steps to reconnect the printer and confirm successful connection.

Steps to complete the 3D printer setup in MatterControl.

Accessing advanced controls for print configuration.

Setting target temperatures for the extruder and heated bed.

Adjusting parameters for the print job itself.

Selecting and using different slice engines like Slic3r, Cura, and MatterSlice.

Setting filament diameter and extruder/bed temperatures.

Setting up custom G-Code for start, end, pause, resume, and cancel.

Opening the editor to customize or create new slice presets.

Preheating the extruder and heated bed before printing.

Configuring Slice Engine, Quality, and Material presets.

Instructions for correctly loading filament onto the printer.

Steps to straighten filament and insert it into the extruder.

Methods for preparing the build plate for better adhesion.

Initiating the print process after preparation.

Recommended extruder and bed temperatures for ABS and PLA.

Understanding and preventing print warping issues.

Common reasons for hot end clogging or jamming.

Explanation of the printer's auto-leveling system.

Defining Z offset using M Code in the custom G-Code field.

Adjusting Z offset in Slice Settings for first layer calibration.

Loading...

Loading...