Lock / Unlock

• To activate the key lock, press and hold the operating button for 8

secondsuntiltheLEDsfortheselectedsettingbrieyash,then

release.

-LEDsashconstantlyat1-secondintervals.

- The key lock is activated: pump settings can no longer be changed.

• The key lock is deactivated in the same manner as it is

activated.

NOTICE: All settings/displays are retained if the power supply

is interrupted.

WILO SE declares that the products mentioned in this statement comply with the provisions of

the following European directives as well as to the national laws in which these provisions have

been adopted:

Lowvoltage2014/35/EU;ElectromagneticCompatibility

2014/30/EU;Energy-relatedproducts2009/125/EC

Inbouw- en bedieningsvoorschriften Wilo-Para 23

nl

• Met de 9e knopdruk is de basisinstelling

(constant-toerental / karakteristiek III) weer bereikt.

Knop blokkeren/

deblokkeren

• De vergrendeling via de bedieningstoets

activeren, 8 seconden indrukken, tot de LED's

van de geselecteerd instelling kort knipperen,

vervolgens loslaten.

LED's knipperen permanent met intervallen

van 1 seconde.

De vergrendeling is geactiveerd, instellingen van

de pomp kunnen niet meer veranderd worden.

• Het deactiveren van de vergrendeling vindt op

dezelfde manier plaats als de activering.

Fabrieksinstelling

activeren

De fabrieksinstelling door drukken en vasthouden

van de bedieningstoets bij gelijktijdig uitschakelen

van pomp activeren.

• De bedieningstoets ten minste 4 seconden ingedrukt

houden.

Alle LED's knipperen 1 seconde.

De LED's van de laatste instelling knipperen

voor 1 seconde.

8. Verschildruk constant

Δp-c

I

9. Constant toerental

III

Led-weergave Regelingstype Karakteristiek

sec8

LET OP

Bij een onderbreking van de spanningsvoorzie-

ning blijven alle instellingen/indicatoren opge-

slagen.

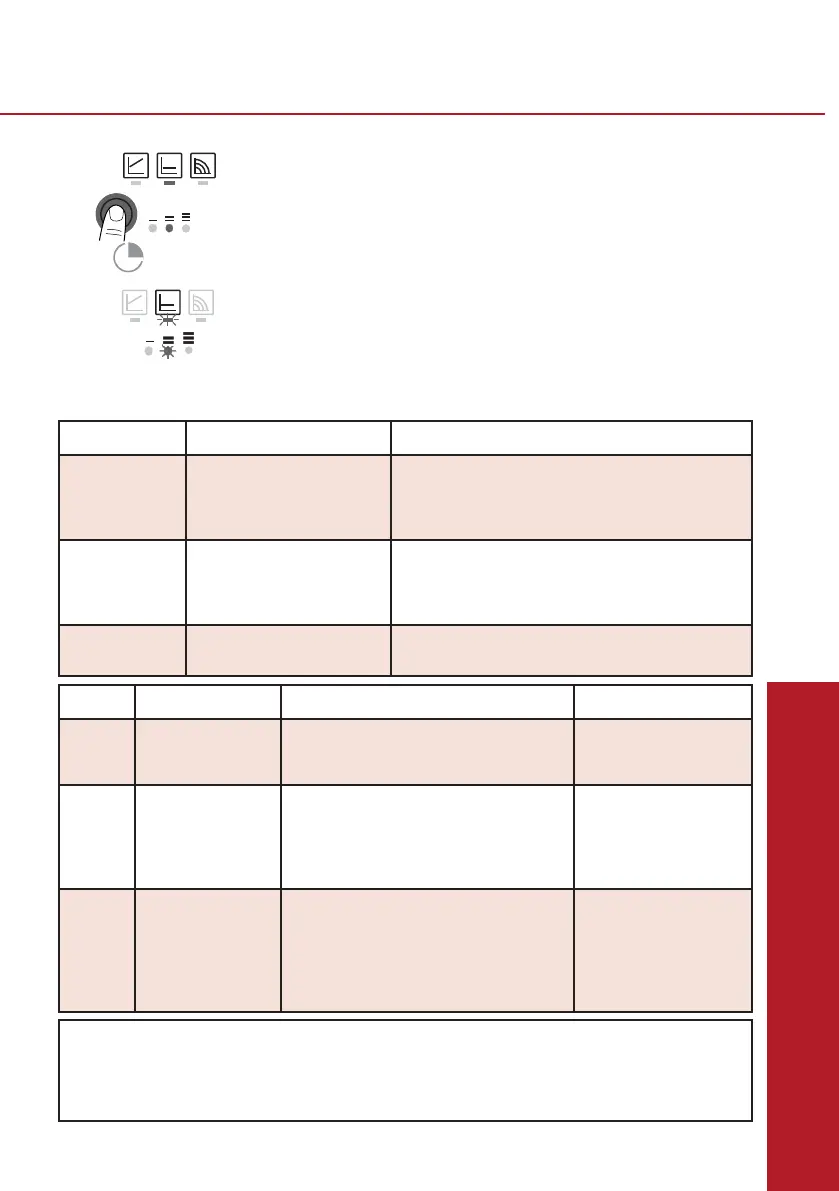

Faults, causes and remedies

LED Faults Causes Remedy

lights up

red

1. Blocking

2. Contacting/

winding

1. Rotor blocked

2. Winding defect

Activate manual restart

or contact customer

service

ashes

red

3. Under/over

voltage

4. Excessive mod-

ule temperature

5. Short-circuit

3. Power supply too low/high on mains

side

4. Module interior too warm

5. Motor current too high

Check mains voltage

and operating con-

ditions, and request

customer service

ashes

red/

green

6. Generator

operation

7. Dry run

8. Overload

6.Waterisowingthroughthepump

hydraulics, but there is no mains

voltage at the pump

7. Air in the pump

8. Sluggish motor, pump operated out-

side specs. Speed lower than normal.

Check the mains volt-

age, water quantity/

pressure and the ambi-

entconditions

Faults Causes Remedy

Pump is not

running while

power supply

on

a. Electrical fuse defective

b. No voltage supply at

pump

a. Check fuses

b. Rectify the power interruption

Noisy pump

c.Cavitationduetoinsuf-

cient suction pressure

c. Increase system pressure within permissible

range

c. Check thermostatic control and set it to a

lower temperature if necessary

Building does

not warm up

d. Thermal output heating

surfaces is too low

d. Increase setpoint

d.ChangecontrolmodefromΔp-ctoΔp-v

Appendices

Loading...

Loading...