2 Rockwell Automation Publication 442G-IN004C-EN-P - January 2020

Multifunctional Access Box with CIP Safety over EtherNet/IP

Power Supply Requirements

Electrical Connection

Connections on Bus Module

This section describes the power connectors, EtherNet/IP connectors,

and recommended cables.

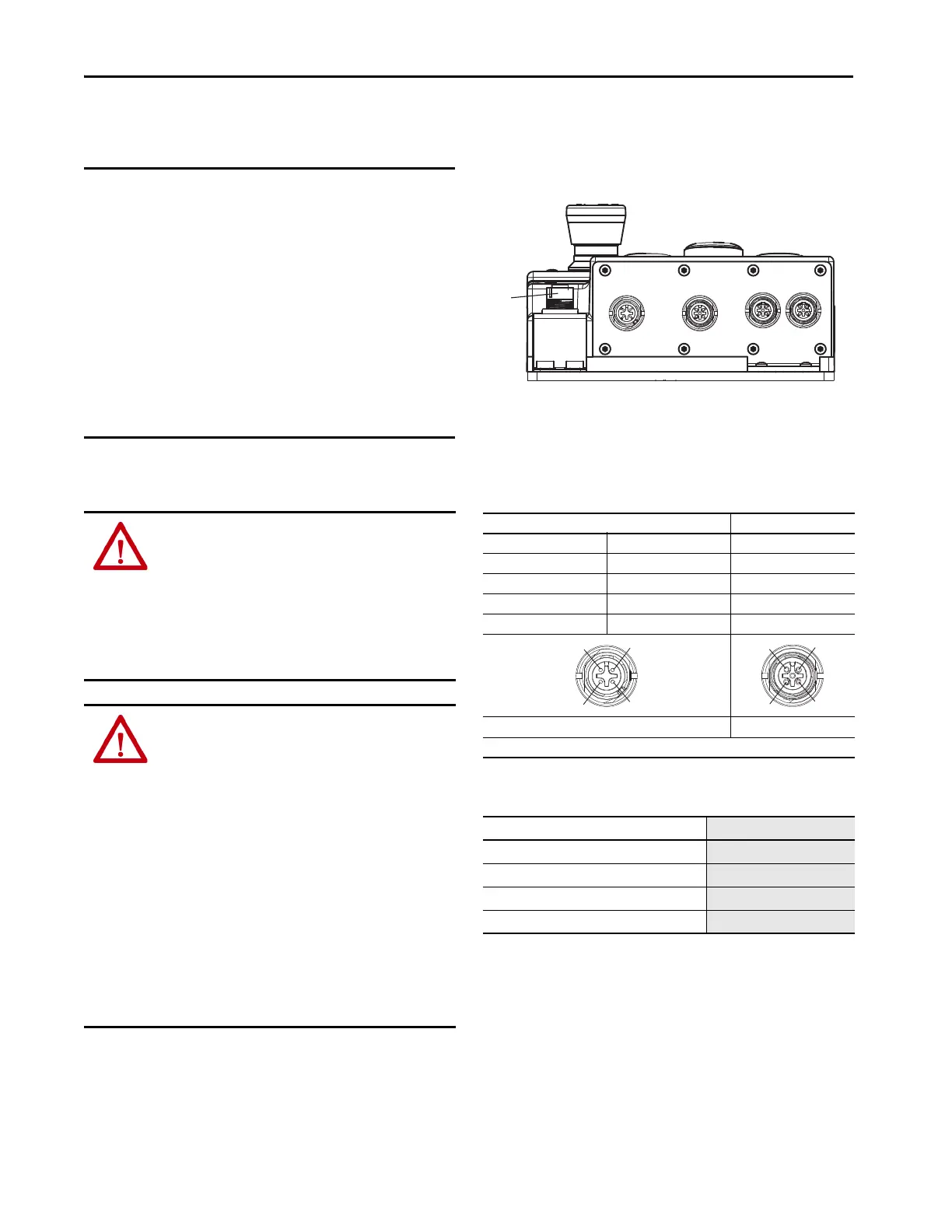

Figure 1 - Connections on Bus Module

Power Connections

The bus module includes the EtherNet/IP connections (X3 and X4,

M12 D-coded) and the power supply connections (X1 and X2).

IMPORTANT • If the device does not appear to function when the

operating voltage is applied (for example, Pwr status

indicator does not illuminate), the safety switch must be

returned to the manufacturer.

• A Class 2 PELV power supply must be used. Alternative

solutions must comply with the following requirements.

- Electrically isolated power supply unit with a

maximum open-circuit voltage of 30V DC and a

limited current of 8 A maximum.

- Electrically isolated power supply unit in

combination with the fuse as per UL 248. This fuse

should be designed for a maximum of 3.3 A and

should be integrated into the 30V DC voltage

section.

• The functional earth ground must be connected. An M6

threaded bore is available on the mounting plate of the

lock/bus module for this purpose.

WARNING: Connect and disconnect wiring cables:

• If you connect or disconnect wiring or cables while the field-

side power is on, an electric arc can occur. This arc could cause

an explosion in hazardous location installations. Be sure that

power is removed or the area is nonhazardous before

proceeding.

• If you connect or disconnect the communication cables while

power is applied to this module or any device on the network,

an electric arc can occur. This arc could cause an explosion in

hazardous location installations.

ATTENTION: Wiring Guidelines

• All electrical connections must be isolated from the main

supply by a safety transformer (according to EN IEC 61558-2-6)

with limited output voltage if there is a fault or by other

equivalent isolation measures.

• Power devices, which are a powerful source of interference,

must be installed in a separate location away from the input

and output circuits for signal processing. The cable routing for

safety circuits must be as far away as possible from the cables

of the power circuits.

• To avoid EMC interference, the physical environment and

operating conditions at the installation site of the device must

comply with the requirements according to the standard

DIN EN 60204-1:2006, section 4.4.2/EMC.

• The mounting of conduits directly on the access box is not

allowed. Cables are only allowed to be connected via suitable

cable glands. Use a UL Listed (QCRV) cable gland suitable for

the related cable diameter (22…17 AWG).

• The functional earth must be connected. An M6 threaded bore

is available on the mounting plate for this purpose.

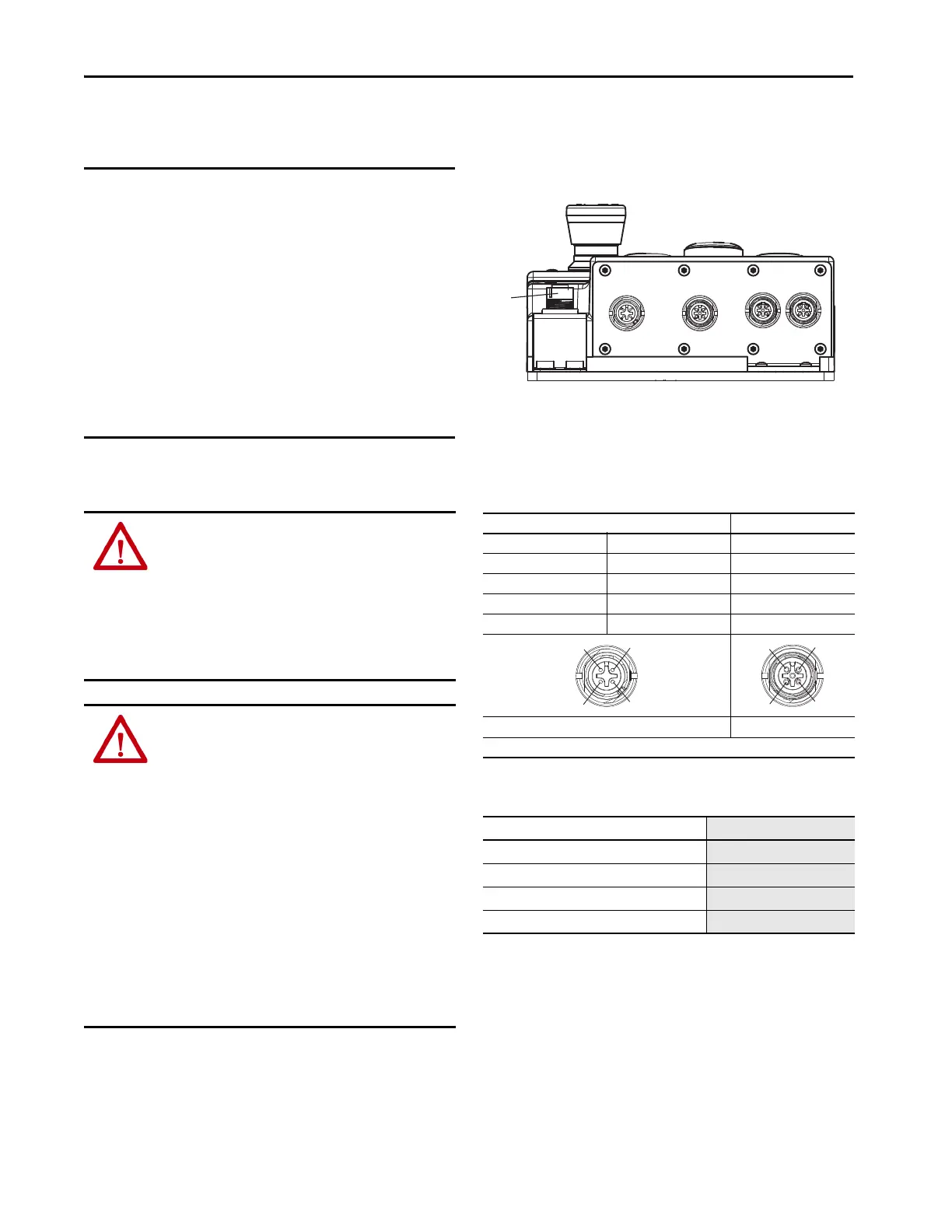

Table 1 - Pinout for Power Connectors (M12 A-coded models)

Pin Description

X1.1 X2.1 24V DC

X1.2 X2.2 Pass through

X1.3 X2.3 0V DC (GND)

X1.4 X2.4 Pass through

X1.5 X2.5 Functional earth

X1 X2

Power supply connector assignment. Connectors X1 and X2, M12 A-coded.

Table 2 - Recommended Micro Power Cables

Description Cat. No.

(1)

(1) Replace -2 (2 m [6.6 ft]) with -5 (5 m [16.4 ft]) or -10 (10 m [32.8 ft]) for additional standard cable lengths.

Micro straight female to flying leads cordset 889D-F4AC-2

Micro straight male to flying leads cordset

889D-M4AC-2

Micro right-angle female to flying leads cordset

889D-R4AC-2

Micro right-angle male to flying leads cordset

889D-E4AC-2

X1

X4X3

X2

IN 24V DC

LINK 1 LINK 2

OUT 24V DC

X5

1

2

43

1 2

43

Loading...

Loading...