Do you have a question about the Roland TrueVIS VF2-640 and is the answer not in the manual?

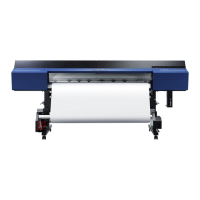

Provides fundamental information about the printer, including its parts, panel, display, and media.

Identifies and describes the various parts of the printer unit, including front and rear components.

Details the buttons, lights, and display screen of the printer's control panel for user interaction.

Explains the elements and indicators displayed on the printer's screen during operation.

Covers information about the types of media used and the conditions for their proper application.

Provides a flowchart illustrating the hierarchy and options within the printer's menu system.

Explains how to set the printer's menu language and measurement units.

Explains the correct procedures for turning the printer's main and sub power on and off.

Guides users through the process of loading roll and sheet media onto the printer.

Details essential adjustments and checks required immediately after the printer has been installed.

Outlines checks to perform before starting print operations, including network and ink status.

Describes how to pause, resume, and cancel printing operations during execution.

Provides instructions for replacing ink and cleaning liquid pouches when depleted.

Details the overall process for printing, including preparations and the actual output.

Covers performing printing tests and normal cleaning to ensure print head readiness.

Details the steps for configuring print settings and starting the output process.

Guides on enhancing print quality through various correction functions and settings.

Fine-tunes the ink landing position for optimal print accuracy and image quality.

Reduces visible horizontal stripes or banding by adjusting media feed calibration.

Explains how to adjust the print head height to accommodate different media types and prevent contact.

Details the specific settings and procedures for using transparent media, which requires manual setup.

Sets the print heater temperature to improve ink adhesion and prevent smudging.

Adjusts the dryer temperature to ensure fast and effective ink drying.

Allows users to save current configurations as presets for quick recall and media setup.

Explains how to load previously saved printer settings for specific media or jobs.

Defines the starting point for printing on the loaded media to ensure accurate placement.

Shortens print time by minimizing print head movement for narrow media or output data.

Explains how to use the dedicated mobile app for printer operation via Bluetooth.

Enables display of the remaining media amount, requiring initial setting for accuracy.

Details the procedure to enable Bluetooth communication for mobile terminal connectivity.

Provides critical safety and handling guidelines for operating the printer correctly and safely.

Outlines the types of maintenance required and the recommended timing for performing them.

Describes essential steps to take when the printer will not be used for an extended duration.

Step-by-step instructions for cleaning the media path to prevent contamination and ensure smooth media transport.

Details safety precautions and environmental guidelines for the proper disposal of discharged fluid.

Explains how to perform printing tests and execute normal cleaning for print head maintenance.

Provides instructions for medium cleaning when normal cleaning fails to resolve print head issues.

Details the manual cleaning process for print heads when automated methods are insufficient.

Covers troubleshooting uneven colors, particularly with white ink, via ink mixing and cleaning.

Addresses uneven color issues with white ink by performing damper cleaning to stabilize ink.

Describes the super cleaning method for severe print head issues like dot drop-out and displacement.

Limits the use of specific print heads to mitigate quality issues like dot drop-out.

Provides emergency cleaning steps for print heads when quality issues persist.

Provides steps for replacing the worn wiper blade and the tray pad for print head cleaning.

Details the procedure for periodic cleaning of the wiper tray to maintain printer function.

Guides users on how to replace the separating knife when it becomes dull.

Addresses issues causing coarse print results or noticeable horizontal stripes on the output.

Helps diagnose and resolve causes of the media becoming soiled during the printing process.

Provides solutions for issues related to unstable colors or unevenness in printed output.

Provides steps to identify and clear media jams to resume printer operation.

Offers solutions for when the print head carriage fails to move or is stuck.

Guides users through checks for when the printer unit fails to power on or start.

Helps resolve issues preventing operation of the printer via the dedicated mobile application.

Lists and explains common messages displayed on the printer's operation panel.

Provides instructions and procedures for safely moving the printer unit.

Step 1 of preparing the machine for movement: safely removing any loaded media.

Step 3 in machine preparation: safely discharging the wiper tray cleaning liquid.

Presents key technical specifications and dimensions of the printer.

Details the maximum printable area and margin settings available for the printer.

| Maximum Print Width | 64 inches |

|---|---|

| Print Resolution | 1200 x 1200 dpi |

| Ink Type | Eco-solvent ink |

| Ink Configuration | CMYK + Orange + Green |

| Media Thickness | Up to 1.0 mm |

| Connectivity | USB 2.0, Ethernet |

| Operating System Compatibility | Windows |

| Power Requirements | 100-240 V, 50/60 Hz |

| Weight | 485 lb (220 kg) |

Loading...

Loading...