C23

----

-

--

------

- Rolls-Royce & Bentley

-------

Air

Conditioning

System

Manual

can

only be

attributed

to

Jack

of

air delivery.

Check

for

operation

and

ensure

that

inlet

and

outlet

ducts

are

unobstructed.

A slightly low

compound

gauge

reading

would be

observed

if there were

any

obstruc-

tions

causing a lack

of

air delivery.

DISCHARGING

REFRIGERANT

When

it is necessary

to

break

any

joint

which is

not

protected

by service valves,

the

refrigerant

must

first

be discharged.

Do

not

discharge in

an

area

where

an

open

flame

is exposed.

The refrigerant does

not

burn,

but

decomposes

and

forms a

poisonous

gas.

Remove

the protective

caps

from

the

compressor

service valves.

Just

'crack'

the high pressure valve

in

a clockwise direction, allowing

the

refrigerant in

the

system

to

be

discharged

to

atmosphere.

Care

must

be

taken

not

to

release

the

refrigerant

too

quickly,

as

thi8 will result in oil being

drawn

out

of

the

system.

The

operation

should

take

at

least fifteen

minutes.

Always use

two

wrenches

in

oppos1t1on

when

disconnecting

Aured

connections,

to

prevent

damage

to

flares

or

tubes.

The

tubes

are

easily twisted.

After

the necessary

repair

has been

made

and

before

re-charging, it is necessary

to

evacuate

and

sweep

the

system,

to

remove

all

the

moisture.

The

compressor

oil

level should be checked,

as

detailed

under

'Compressor'.

EVACUATING

The

use

of

a vacuum

pump

is

recommended

for

evacuation

but

when

not

available the

compressor

may

be utilised as follows:

Fit

the

manifold

gauge

unit

to

the

compressor

as

illustrated

.

Forward-seat

the

high pressure service

valve

of

the

compressor

hy

rotating

it

in

a clockwise

direction

to

the

end

of

its travel.

Open

the pressure

valve

of

the manifold gauge set by

rotating

it in

an

anti-clockwise direction fully.

Close

the

vacuum

valve

of

the

manifold

gauge

set

by

rotating

it in a clock wise direction.

Just

'crack'

the

low

pressure service valve by giving

half

a

turn

in

a

clockwise

direction.

Start

the

engine

and

run

on

'slow idle'. Switch

on

the

blowers

in

the

'Hl'

position. Observe the

vacuum

B~5

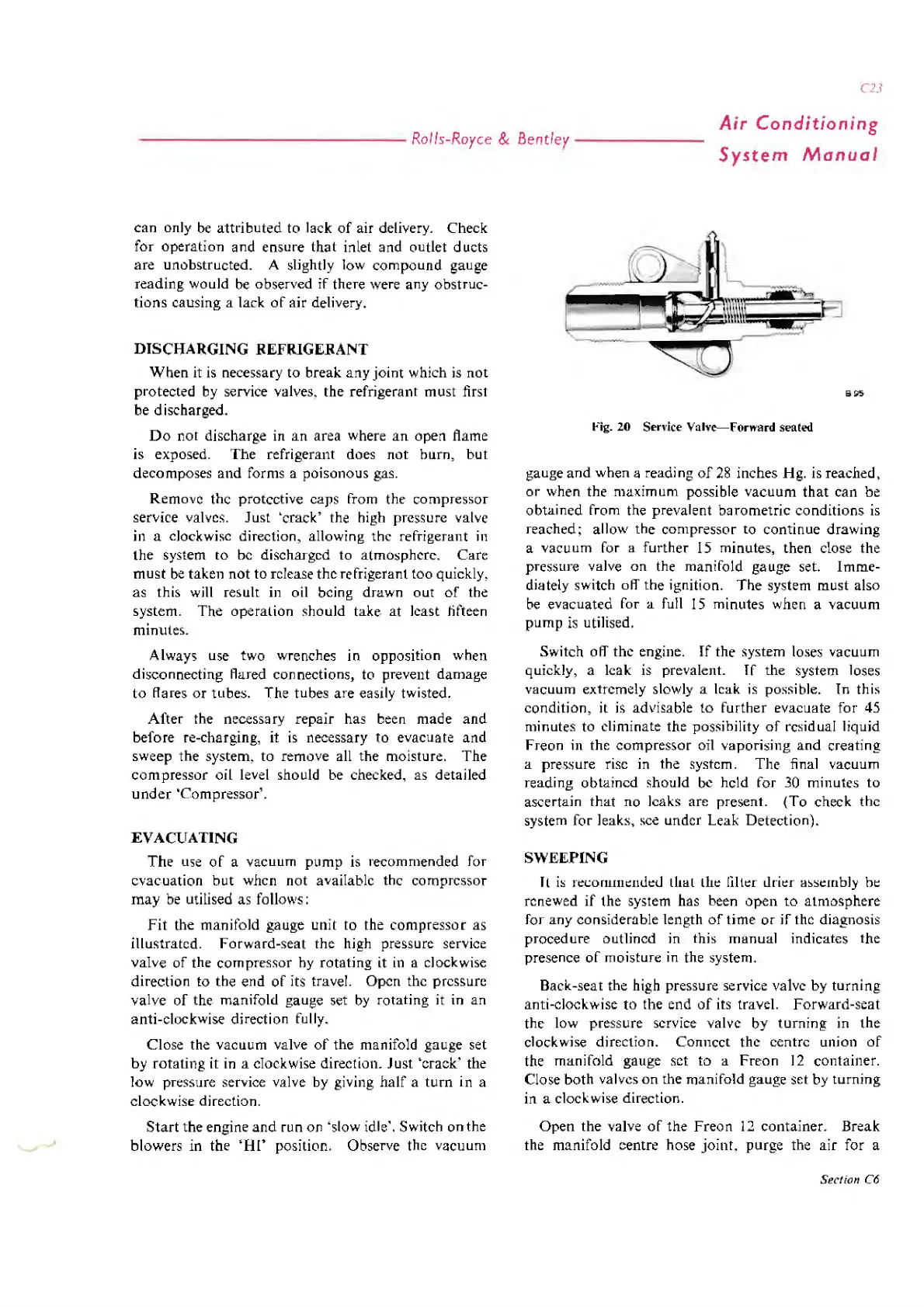

Fig.

20

Service

Valve-Forward

seated

gauge

and

when

a reading

of

28

inches

Hg. is

reached,

or

when

the

maximum

possible

vacuum

that

can

be

obtained

from the prevalent

barometric

conditions

is

reached;

allow

the

compressor

to

continue

drawing

a

vacuum

for a

further

15

minutes,

then

close the

pressure valve

on

the

manifold

gauge

set.

Imme-

diately switch off the ignition.

The

system

must

also

be

evacuated

for a full

15

minutes when a

vacuum

pump

is utilised.

Switch off

the

engine.

If

the system loses vacuum

quickly, a leak is prevalent.

Tf

the

system loses

vacuum extremely slowly a leak is possible.

In this

condition,

it is advisable

to

further

evacuate

for

45

minutes

to

eliminate the possibility

of

residual liquid

Freon

in the

compressor

oil

vaporising

and

creating

a pressure rise in the system.

The

final vacuum

reading

obtained

should be held for

30

minutes

to

ascertain

that

no leaks are present.

(To

check

the

system

for

leaks, see

under

Leak

Detection).

SWEEPING

It

is

n:l:ommi::11<l1c:<l

lhal

Lht:

J"illt:r

tlrit:r asst:mbly

bt:

renewed

if

the

system has been

open

to

atmosphere

for

any

considerable length

of

time

or

if

the diagnosis

procedure

outlined

in this

manual

indicates

the

presence

of

moisture

in

the system.

Back-seat the high pressure service valve by

turning

anti-clockwise

to

the end

of

its travel.

Forward-seat

the

low pressure service valve by

turning

in

the

clockwise direction.

Connect

the

centre

union

of

the

manifold

gauge set

to

a

Freon

12

container.

Close

both

valves

on

the

manifold

gauge set by

turning

in a clockwise direction.

Open

the

valve

of

the

Freon

12

container.

Break

the

manifold

centre hose

joint,

purge

the

air

for

a

Section C6

Loading...

Loading...