To add oil, remove the plug on the top of the transmission and fill with USP extra-heavy white mineral oil

(Ross Oil No. 15040014, or Exxon Primol 355, or equivalent) until oil level is even with the oil level plug.

Replace the plug on the top and the side of the transmission.

To drain the oil a drain tube may be used from the drain plug on the side of the transmission and placed

through the drainage hole nearby in the bottom of the tenderizer cabinet.

7.3 ADJUSTMENTS/SPECIFIC REPAIRS

Conveyor link belt may stretch after use. Do no allow conveyor chain to drag on the tenderizer cabinet.

To tighten belt use adjuster screws item number 33 shown on page 5-5 of this Instruction handbook. If

there is still too much slack, remove one of the belt links.

Do not allow the chain drive for the height adjusting mechanism to become too loose. If the chain gets

loose enough to skip a tooth on the sprocket, a complete readjustment of the height mechanism would

be necessary. See “Head Height Adjustment” on next page.

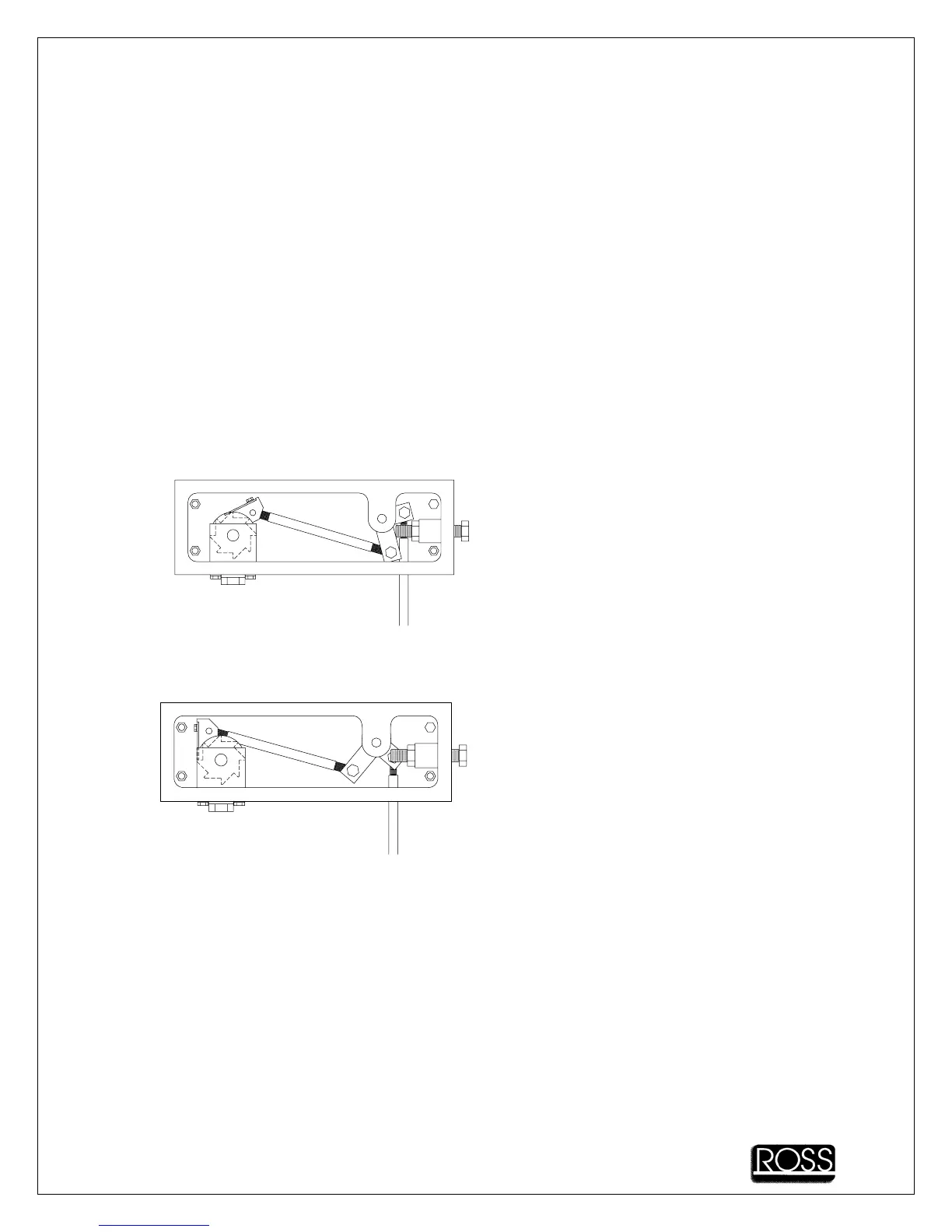

7.3.1 CONVEYOR BOX

This is how the conveyor box should appear when

the conveyor is at rest and not advancing. The index

arm and pawl has pivoted back almost far enough to

drop behind a second tooth. The pull rod (see page

5-11), shown going though the bottom of the box, is

being pushed up by the conveyor return spring

located inside of the cabinet, and the bell crank is

resting against the bell crank stop bolt. See figure

on page 5-4.

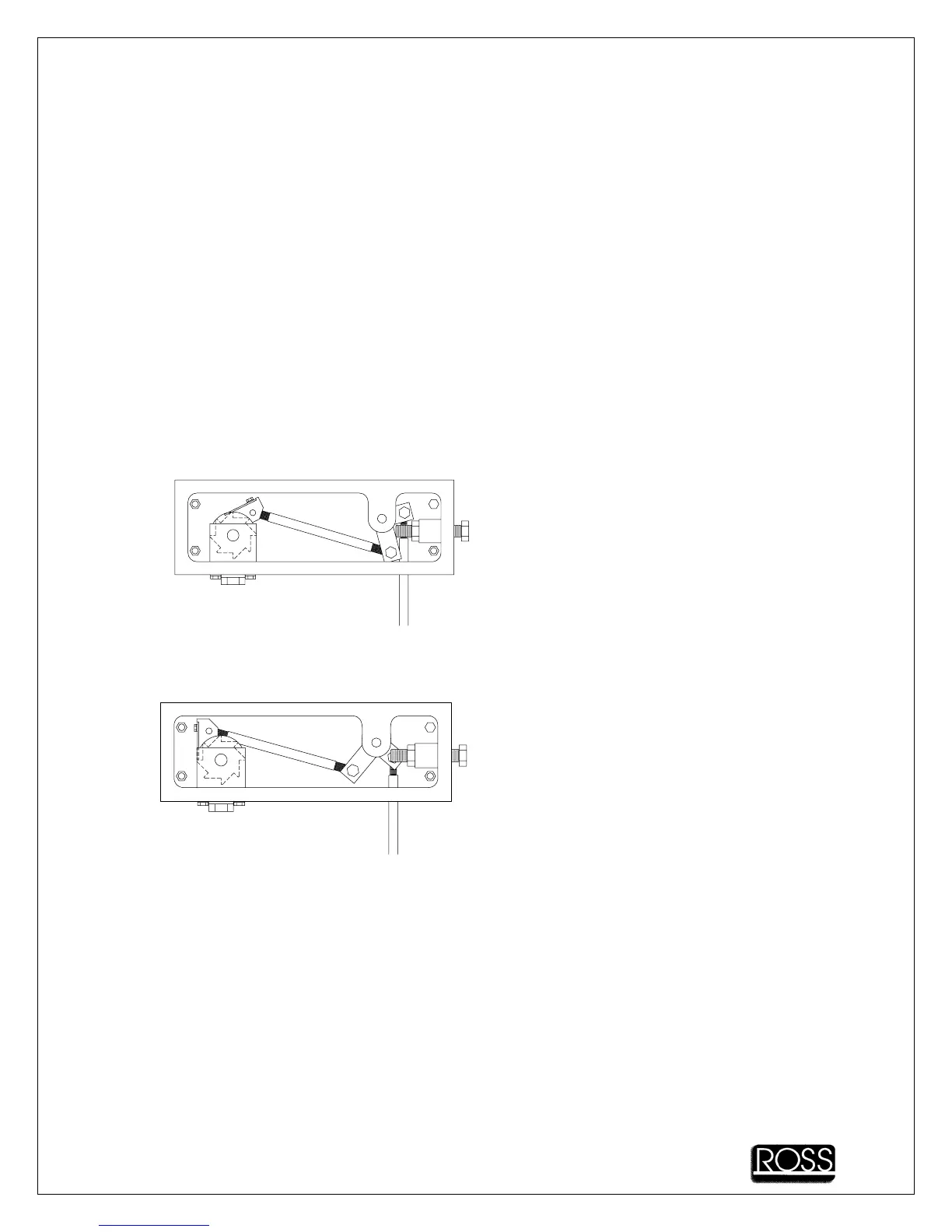

When the conveyor is fully advanced the index arm

is pointing almost straight down.

When set as shown, the conveyor should advance

correctly when loaded with product. See the

troubleshooting section for problems concerning the

conveyor drive system.

MN700-MC0010

7-2

Loading...

Loading...