8

seal rings).

Gearmotors should be protected whenever possible and by appropri-

ate means from solar radiation and extremes of weather; weather

protection becomes essential when low speed shaft is vertically

disposed.

For ambient temperature greater than +40 °C or less than 0 °C,

consult ROSSI MOTORIDUTTORI.

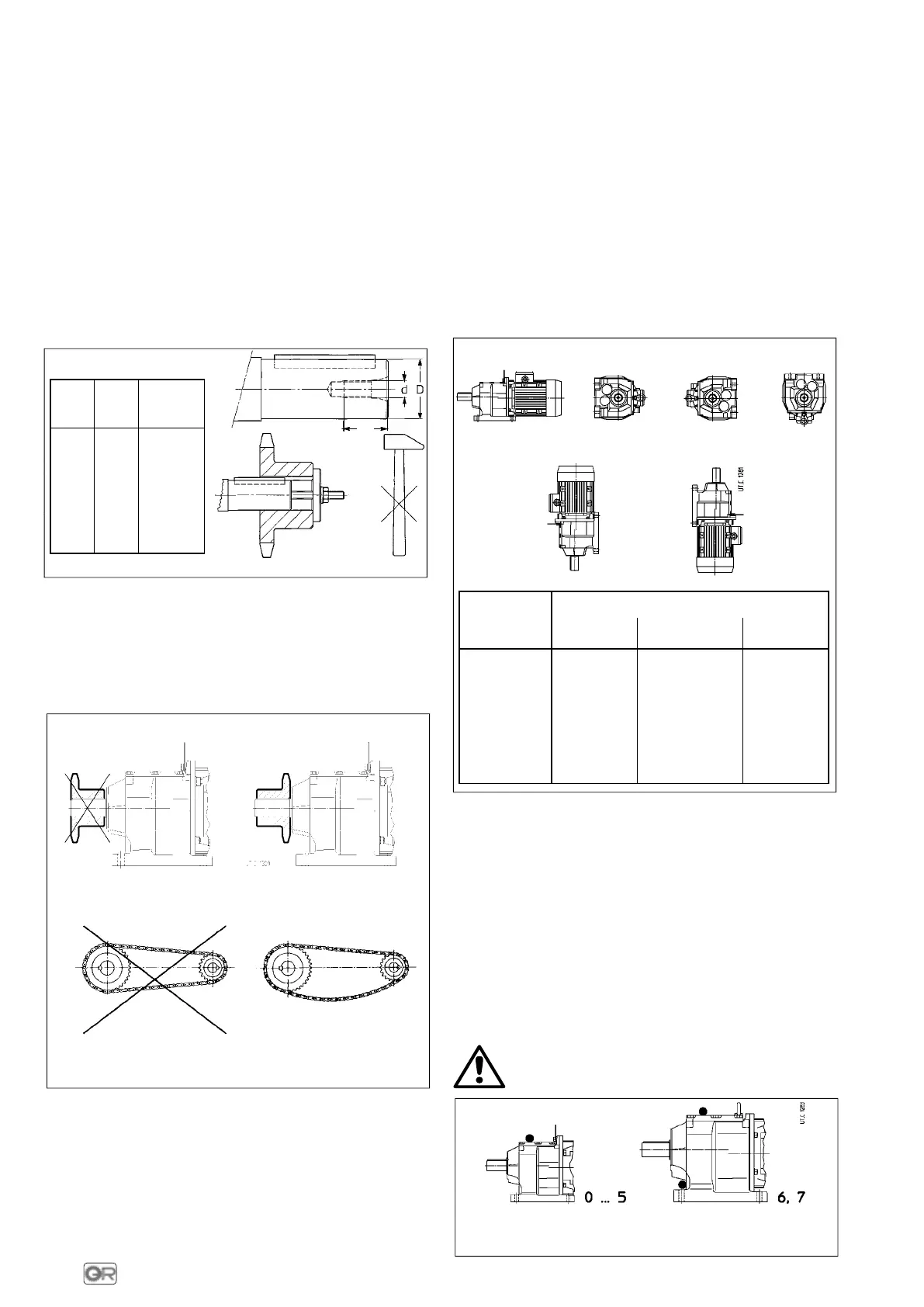

5.2 - Fitting of components to shaft ends

It is recommended that the holes of parts keyed onto shaft ends

should be machined to K7 tolerance (H7 if load is uniform and

light).

Before mounting, thoroughly clean mating surfaces and lubricate

against seizure and fretting corrosion.

Attention! Installing and removal operations should b e carried out

with the aid of jacking screws and pullers using the tapped hole

at the shaft butt-end (see table in fig. 3) taking care to avoid

impacts and shocks which may irremediably damage the bear-

ings, the circlips, or other parts.

The couplings having a tip speed on external diameter up to 20

m/s must be statically balanced; for higher tip speeds they must be

dynamically balanced.

- 5.2 - Fitting of components to shaft ends

It is recommended that the holes of parts keyed onto shaft ends

should be machined to K7 tolerance (H7 it load is uniform and

light).

Before mounting, thoroughly clean mating surfaces and lubricate

against seizure and fretting corrosion.

Attention! Installing and removal operations should be carried out

with the aid of jacking screws and pullers using the tapped hole at

the shaft butt-end (see table in fig. 3) taking care to avoid impacts

and shocks which may irremediably damage the bearings, the

circlips.

The couplings having a tip speed on external diameter up to 20 m/s

must be statically balanced; for higher tip speeds they must be

dynamically balanced.

Shaft end

Fig. 3

UT.C 886

Gear

red

size

Ø D Ø d x l

0

20 k6 M 6 x 16

1

20 k6 M 6 x 16

2

25 k6 M 10 x 26

3

25 k6 M 10 x 26

4

30 k6 M 10 x 26

5

35 k6 M 12 x 32

6

35 k6 M 12 x 32

7

40 k6 M 16 x 40

l

Where the transmission link between gear reducer and machine or

motor generates shaft end loads, (see fig. 4), ensure that:

– loads do not rise above catalogue values;

– transmission overhang is kept to a minimum;

– gear-type transmissions must guarantee a minimum of backlash

on all mating flanks;

– drive-chains should not be tensioned (if necessary – alternating

loads and/or motion – foresee suitable chain tighteners);

– drive-belts should not be over-tensioned.

UT.C 117

Fig. 3

Incorrect Correct

Incorrect Correct

6 - Lubrication

6.1 - General

Gearmotors are supplied FILLED WITH synthetic OIL (KLÜBER

Klübersynth GH 6-220, MOBIL Glygoyle 30, SHELL Tivela Oil S 220)

providing lubrication «for life» – assuming pollution-free surround-

ings – for gear pairs and bearings (oil-bath or splash lubrication).

However, for vertical mounting positions V5 and V6 upper bearings

are independently lubricated and are filled with special grease

(SHELL ALVANIA RL3 for ball bearings, KLÜBER STABURAGS NBU

8 EP for roller bearings) providing lubrication «for life», assuming

pollution-free surroundings. The same applies for motor bearings

and backstop devices when fitted to motors.

Ambient temperature range 0 ÷ 40 °C with peaks of -20 °C and

+50 °C.

Should there be either a possibility of lubricant contamination or a

particular type of duty-cycle, it is good policy to check on the state

of the lubricant (oil and possible grease) every year or 2 years and,

in any case, provide for lubricant replace every 2 or 4 years.

6.2 - Mounting position

Size

Oil quantity [l]

B3 B6, B7, B8, V6 V5

0

0,2 0,4 0,4

1

0,4 0,6 0,7

2

0,6 0,8 1

3

0,6 0,8 1

4

1,2 1,7 2

5

1,2 1,7 2

6

1,9 2,8 3,3

7

2,3 3,2 3,8

B3 B6 B7

B8

V5 V6

Fig. 5

Unless otherwise stated, geamotors are supplied in mounting posi-

tion B3 (see fig. 5) which, being standard, is omitted from the

designation and from the nameplate.

The mounting position ordered affects the quantity of lubricant

which the gear reducer is filled with before delivering as well as

possible bearings with independent lubrication (see ch. 6.1)).

Important: be sure that the gearmotor is installed as per mounting

position ordered and stated on the name plate. If the gearmotor is

installed in a different mounting position verify, according to the

values given in the table in fig. 5, that the oil quantity does not

change; if so, adjust it consequently. Moreover, V5 and V6 vertical

mounting positions need the upper bearings to be lubricated with

special grease (see ch. 6.1).

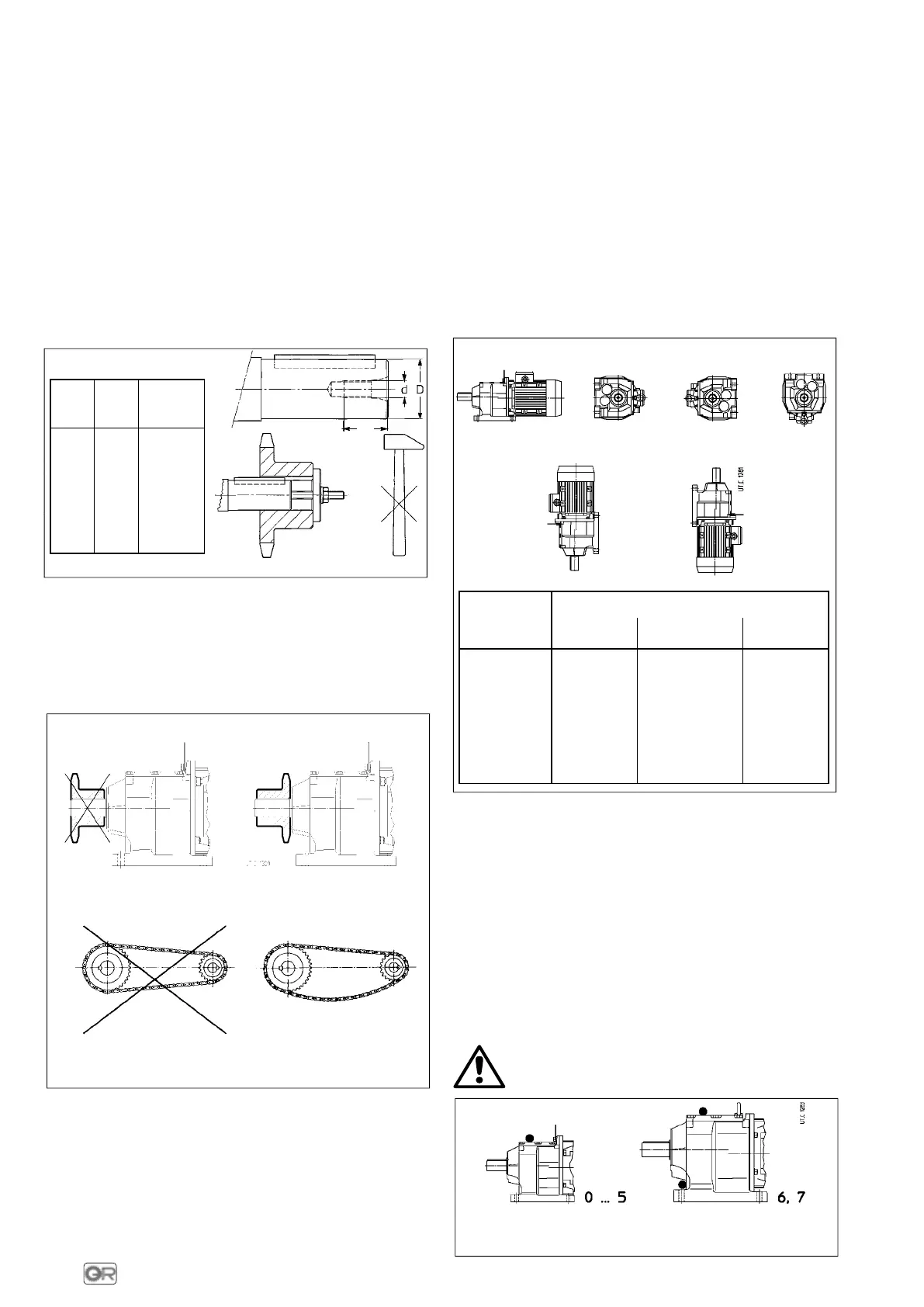

6.3 - Plug position

Gearmotors are provided with 1 (sizes 0 … 5) or 2 plugs (sizes 6 and

7), made of light alloy, positioned as per figure below. No level plug

is supplied.

Attention! Before loosening the plugs waint until gear

reducer has become cold (see ch. 8).

Thread

Tightening

torque

G 1/8"

3,5 N m

Thread

Tightening

torque

G 1/4"

7 N m

Loading...

Loading...