31

17-04-2003

01

15-01-2004

DATE

COMPILER TECO/ATI

REG. CODE

1-5302-467

MODEL N°

50707

DATE OF ISSUE

REVISION

ENDORSED

38 39

35 36

37

VIII

40 41

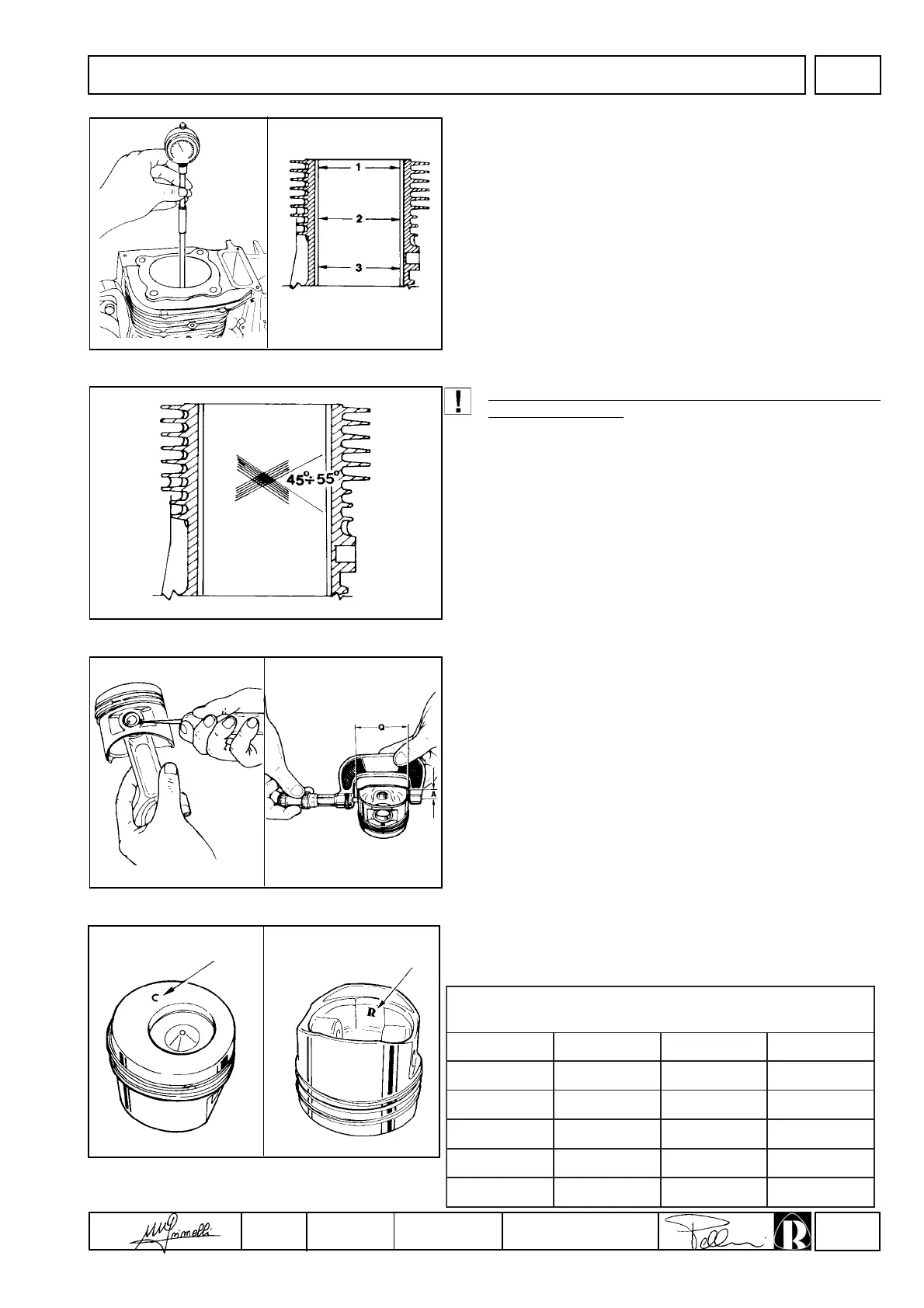

Cylinder

Set a bore gauge to zero with a calibrated ring.

Check diameter at 1, 2 and 3; repeat the operation at the same points

after turning the bore gauge 90°.

If wear exceeds the max. given value by 0.05, bore the cylinder and fit

oversize piston and rings.

See fig. 40 and 41 for cylinder diameter values.

Do not manually hone the cylinder bore surfaces with emery

cloth or other means.

Cylinder roughness

The cross-hatch pattern should be at an angle of 45°-55°; lines

should be uniform and clear in both directions.

Average roughness must range between 0.5 mm 1 µm.

The cylinder surface which comes into contact with piston rings

should be machined with the plateau method.

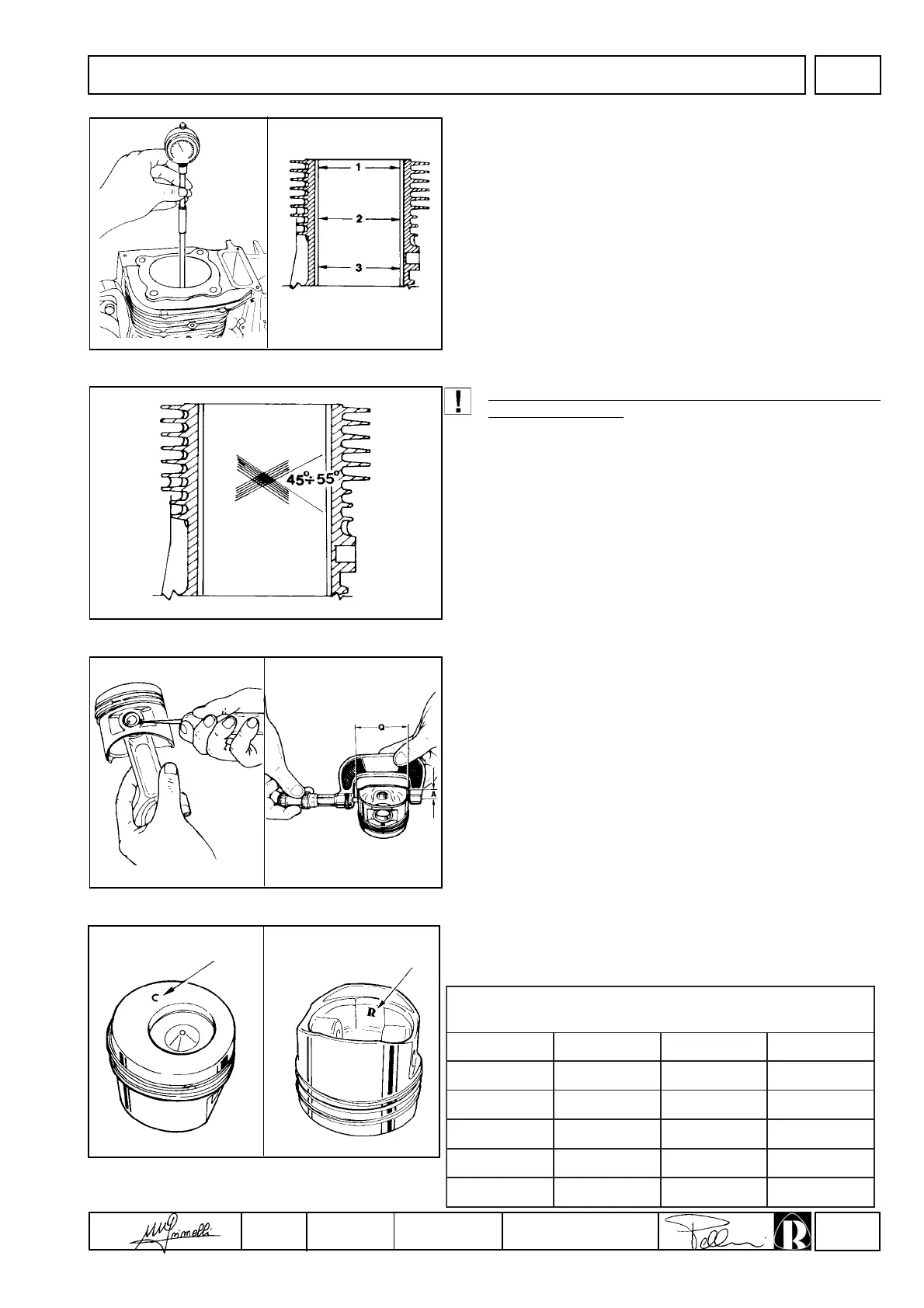

Piston

Being of low expansion type, the piston allows small clearances

between piston and cylinder and, thus, oil consumption is reduced.

Remove circlips and piston pin.

Remove piston rings and clean grooves.

Measure diameter Q at the A distance from the skirt bottom (A = 12

mm).

Replace the piston and piston rings if wear on the diameter is 0.05

mm more than the minimum value given (see table in fig. 40-41).

Note: Oversize pistons of 0.50 and 1.00 mm are available.

Dimensions of pistons and cylinders, Logo

Logo can be found inside the piston

DISASSEMBLY/REASSEMBLY

)mm(snoisnemidrednilycdnasnotsiP

sredniliCØnotsiPØecnaraelC

05YR

510,96÷00.96079,86÷559,8660.0÷30.0

07YR

51.87÷00.87079.77÷559.7760.0÷30.0

57YR

510.28÷00.28079.18÷559.1860.0÷30.0

301YR

510,28÷00,28079,18÷559,1860.0÷30.0

011YR

510,68÷00,68079,58÷559,5860.0÷30.0

Loading...

Loading...