54

17-04-2003

01

15-01-2004

DATE

COMPILER TECO/ATI

REG. CODE

1-5302-584

MODEL N°

50871

DATE OF ISSUE

REVISION

ENDORSED

107

106

105

X

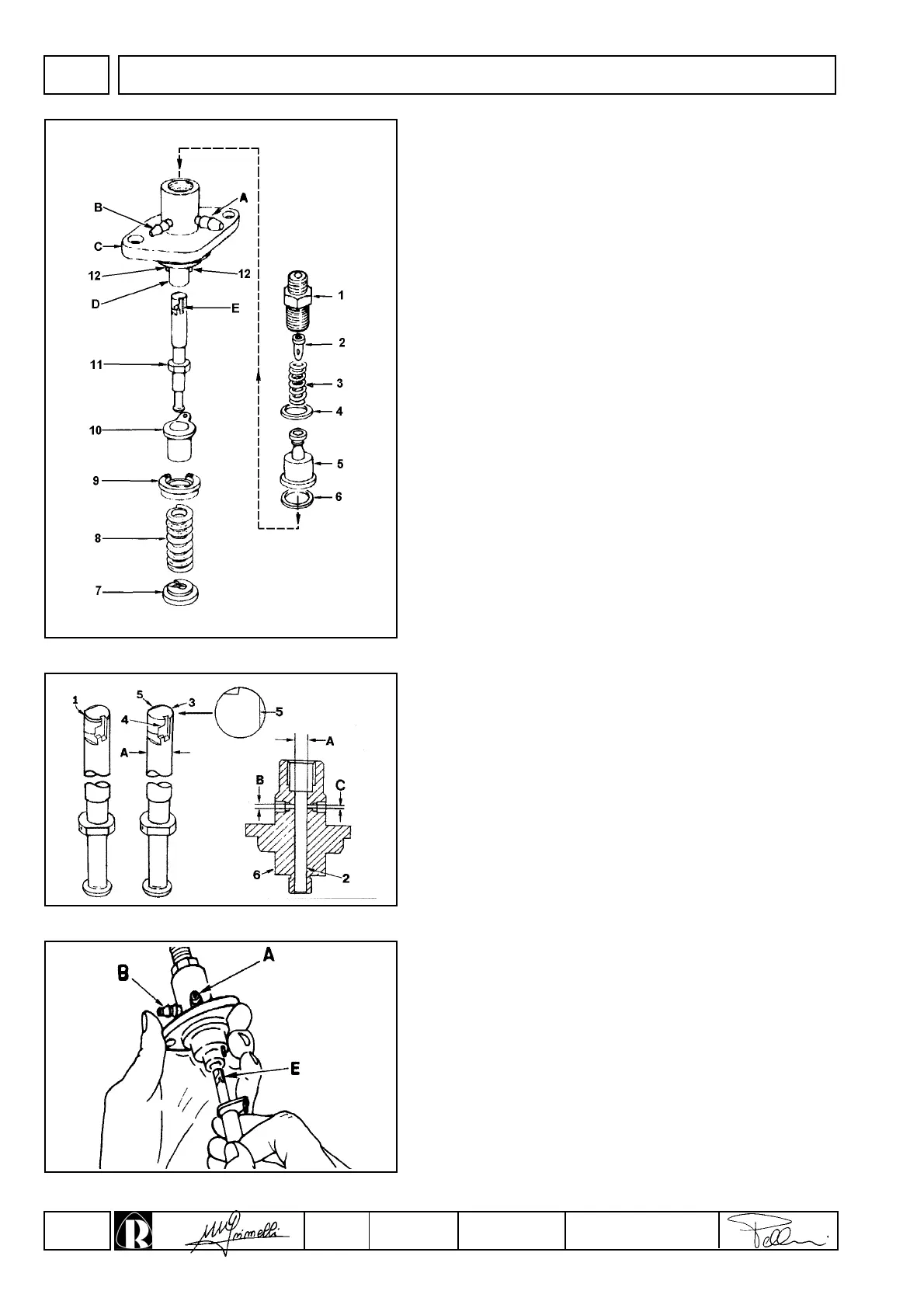

Injection pump components and disassembly

1 Delivery union

2 Filler

3 Spring

4 Gasket

5 Valve

6 Gasket

7 Spring retainer

8 Spring

9 Spring plate

10 Rack

11 Plunger

12 Pin

A = Fuel outlet union

B = Fuel intake union

C = Fastening

D = Barrel

E = RH helix

Demount in compliance with the numeric order.

Plate 9 is held firm by pins 12. Lever up by inserting a tool between

the plate and the body of the pump.

The volume shifted by delivery valve 5 is 15

mm

3

in the pump of RY

70-75 and 25 mm³ in the pump of RY 50 is 21 mm

3

in the pump of

RY 103-110

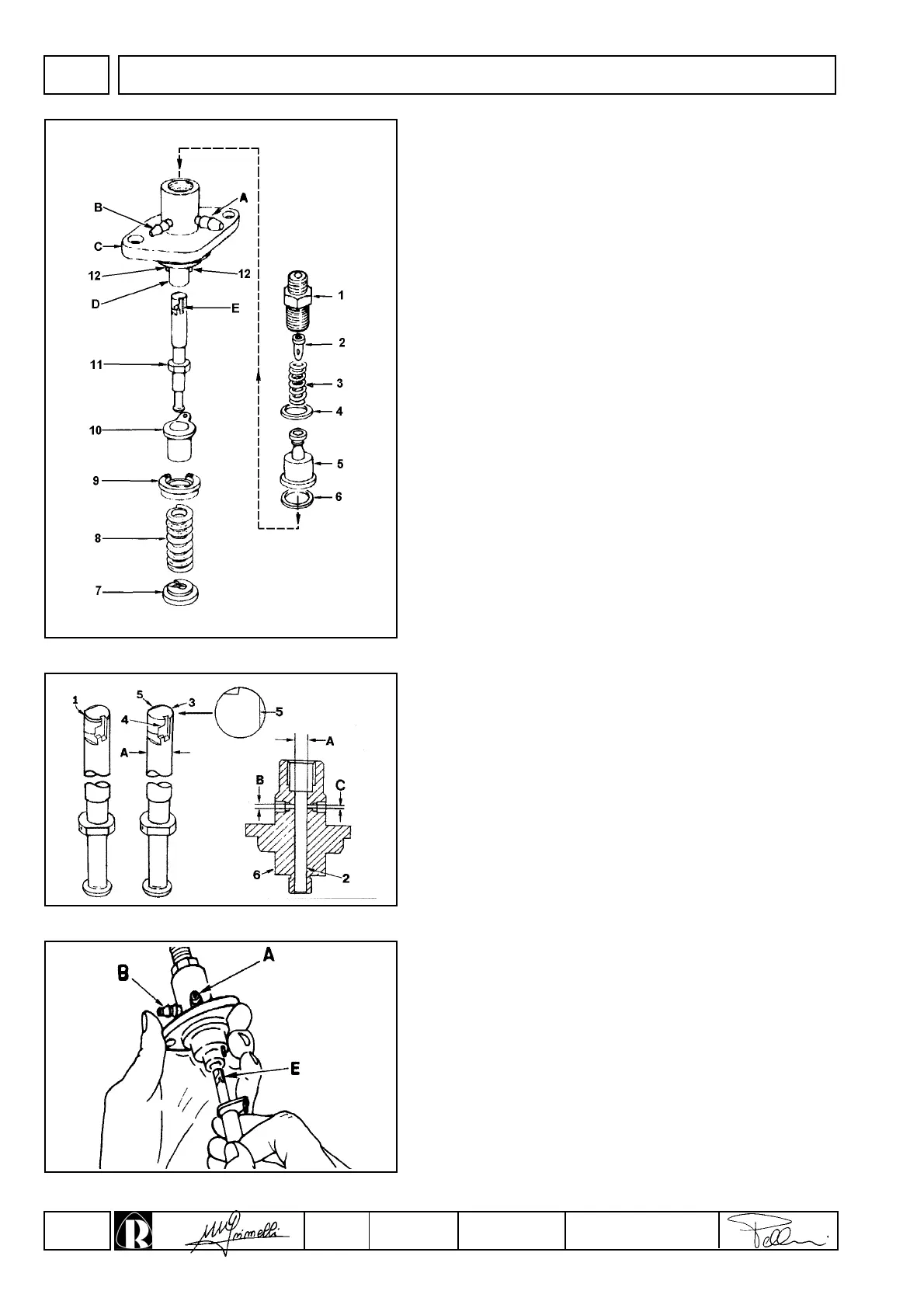

Injection pump, body, plunger and delivery valve

Components: Dimensions mm:

1 Delivery valve A = 5.50 (nominal diam.) RY 50-70-75

2 Barrel A = 7,00 (nominal diam.) RY 103-110

3 Plunger A = 6,00 (nominal diam.) RY 70-75 EPA

4

Right helix B = 2.00 / 2.03

5 Delay notch C = 1.50 /1.53

6 Pump body

7 Collar

Note: The injection pump installed in engines for small vehicles,

soundproof generating sets, EPA and RY 103-110 engines,

are characterised by the inclusion of a collar 1 which

contributes to noise-reduction.

Injection pump refitting

The plunger is fitted with helix E facing towards the outlet union A; if

it is mistakenly fitted with the helix facing the intake coupling B the

injection pump no longer operates (there is no danger of engine

runaway); complete refitting following fig. 107.

FUEL SYSTEM

Loading...

Loading...