Fig.29

Material

Supports

Material

Supports

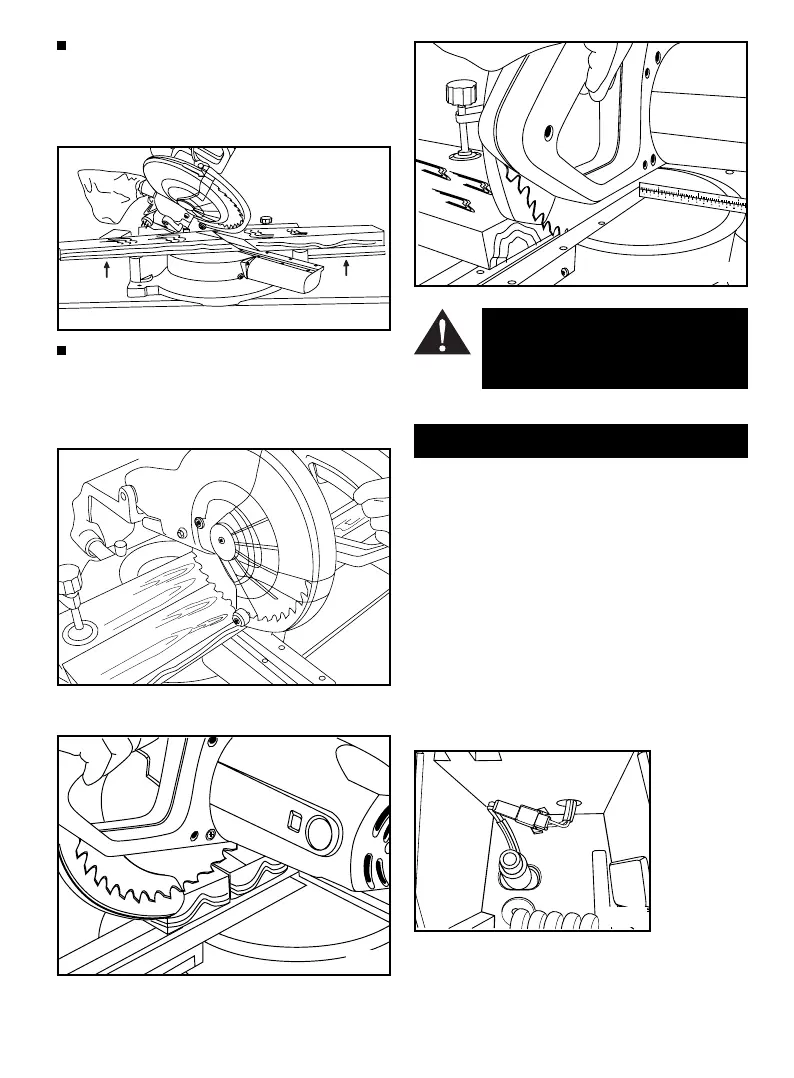

SUPPORT LONG WORKPIECES (Fig.26)

The two material supports are designed to support timber so

it does not sag. The material supports should let the

workpiece lay flat on the base of the saw and the work table

during the cutting operations. Use the vice of clamp the

workpiece.

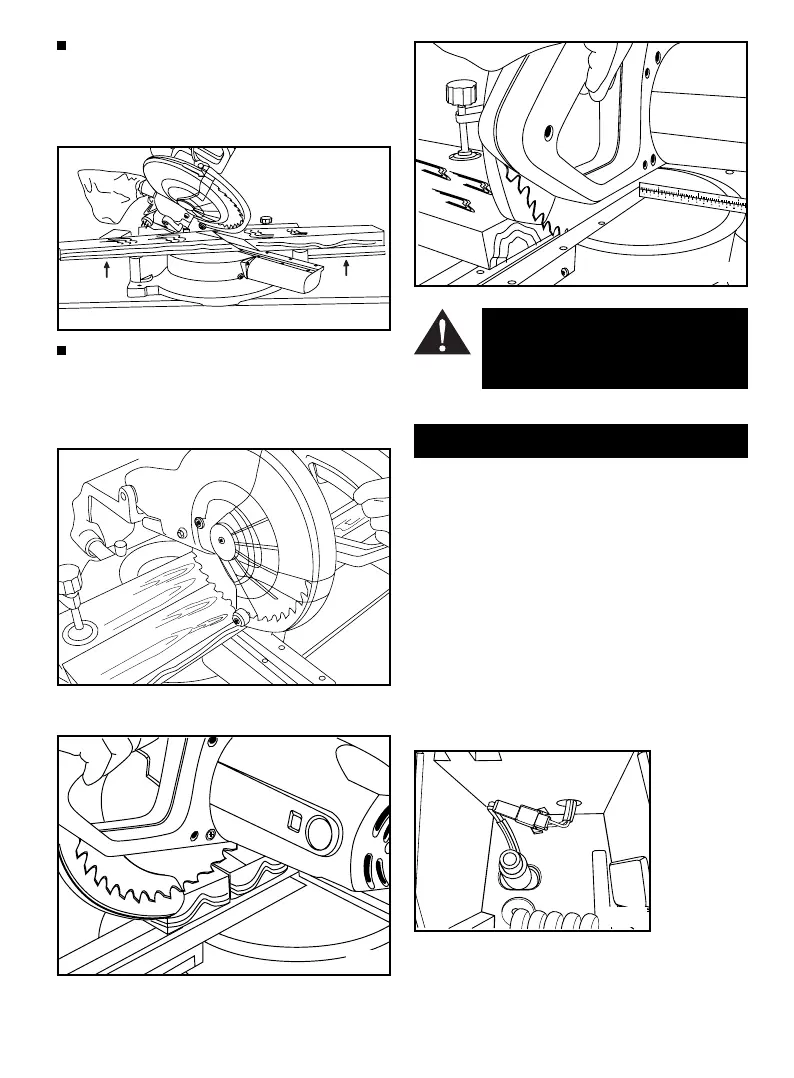

CUTTING LARGER WORKPIECES WITH SLIDE ACTION

When cutting large workpieces with the slide action, the

workpiece is placed squarely against the rear fence and is

firmly locked in the vice.

Grasp the saw handle firmly, press down the lock-off switch

and depress the trigger switch. (Fig.27)

Slide the cutting head away from the rear fence to the outer-

most position. (Fig.28)

Slowly lower the blade into and through the workpiece and

push the blade through the timber towards the rear fence.

(Fig.29)

WARNING: Never place undue force on the

saw handle in a right or left direction as this will

misalign the head and result in an inaccurate

cut.

LASER BEAM (Fig.30)

The light from the laser beam allows you to line up precisely

the cutting angle and the exact position of the workpiece on

the bench.

The laser beam can be switched on as requiredd:

Press laser on/off switch to turn the laser on and press the

switch again to turn the laser off.

The network cable supplies power to the laser. The laser beam

should be aligned before being used for the first time.

•

Set bench to angle position 0˚.

•

Loosen off laser-alignment screw slightly.

•

Switch the laser on and aligh the beam so that it points

exactly at the 0˚ gauge mark of mitre cut adjuster.

LASERLASER

LASERLASER

LASER

Fig.26

Fig.28

Fig.27

LASER

Fig.30

Page 12

Loading...

Loading...