5

See Figure 6.

The drill has a two-speed gear train designed for drilling

or driving at or ) speeds. A slide switch is

located on top of the drill to select either or

speed. When using drill in the speed range, speed

will decrease and unit will have more power and torque.

When using drill in the speed range, speed will

increase and unit will have less power and torque. Use

speed for high power and torque applications and

speed for fast drilling or driving applications.

If you have difficulty changing from one gear

range to the other, turn the chuck by hand until the gears

engage.

Never change gears while the tool is running.

Failure to obey this caution could result in

serious damage to the drill.

See Figure 7.

The Quick Mode Selector allows you to quickly switch

from drill mode to drive mode.

In general, drill mode should be used for drilling and

other heavy duty applications. Drive mode should be

used for driving screws.percussion mode should be used

for impact drilling.

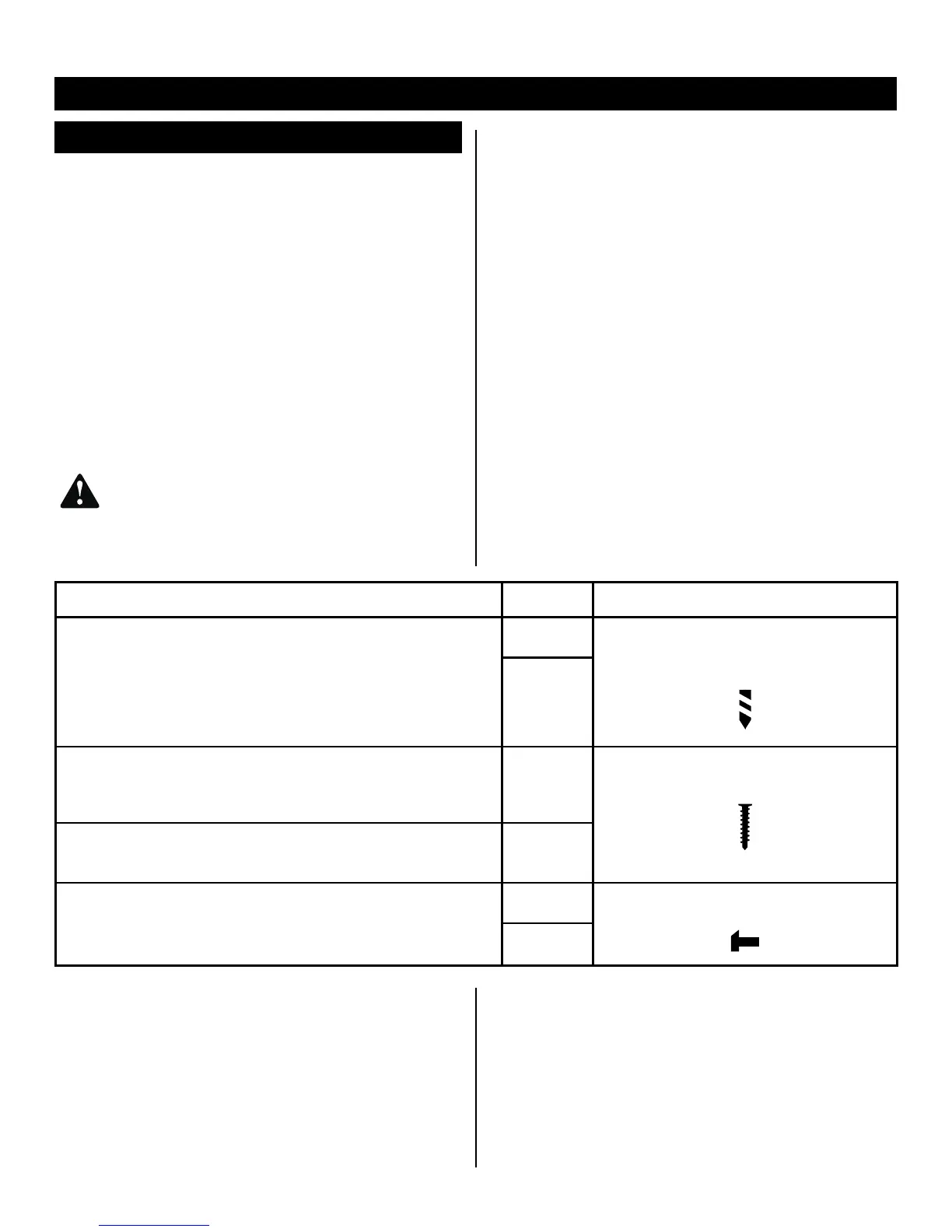

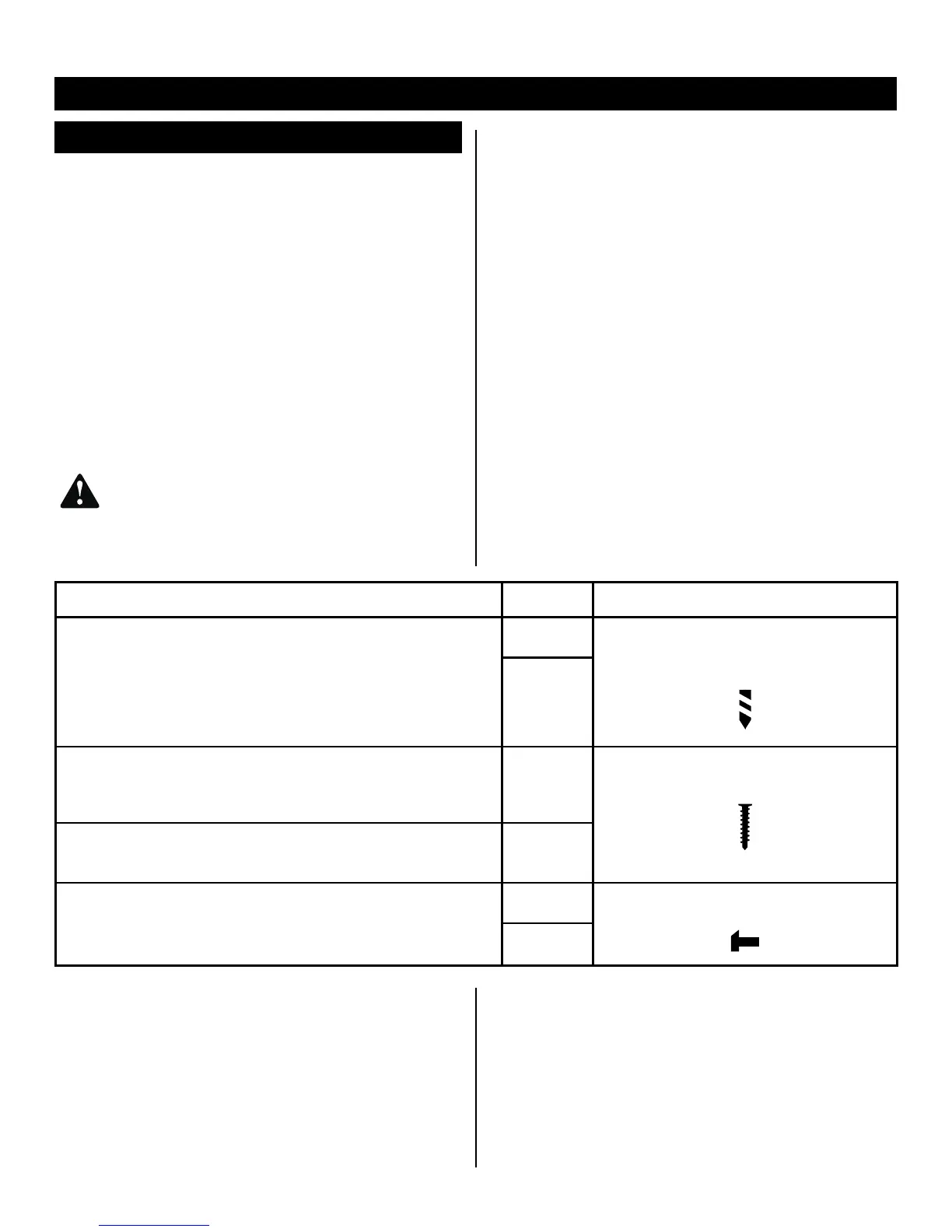

See Figure 6-7.

Using the chart below, choose correct speed and mode

the type of bit, fastener, and material you will be using.

Choose your

Choose the correct

Choose the correct

• Lag screws up to 9.5 mm dia. by 38.1 mm long

• Hole saw up to 50.8 mm

• Spade bits up to 38.1 mm

• Drill bits up to 12.7 mm

• Drilling into metal

• Concrete screws

1/LOW

DRILL MODE

(TORQUE ADJUSMENT NOT ACTIVE)

2/HIGH

• Drill bits up to 6.4 mm

• Deck or wood screws up to 63.5 mm long

• Self tapping screws

1/LOW

DRIVE MODE

• Deck or wood screws up to 63.5 mm long

• Small screws or delicate work that requires more control

2/HIGH

• Masonry bit up to 12.7 mm

1/LOW

HAMMER MODE

(TORQUE ADJUSMENT NOT ACTIVE)

2/HIGH

See Figure 8.

When using the drill-driver for various driving applications,

it becomes necessary to increase or decrease the torque

in order to help prevent the possibility of damaging

screw heads, threads, workpiece, etc. In general, torque

intensity should correspond to the screw diameter. If the

torque is too high or the screws too small, the screws

may be damaged or broken.

The torque is adjusted by rotating the torque adjustment ring.

The torque is greater when the torque adjustment ring

is set on a higher setting. The torque is less when the

torque adjustment ring is set on a lower setting.

The proper setting depends on the type of material and

the size of screw you are using.

Loading...

Loading...