222 Car care

Two-coat enamel

As the name implies, two-coat enamel is

applied in two operations. The first coat, the

base color, contains the pigment, metal

flakes and binder. The second coat consists

of a clear enamel, which provides the final

gloss for the paintwork and protects the

base from moisture and environmental con-

taminants.

Touch-up stone-chip damage as follows:

1 Thoroughly clean the damaged area.

2 Then apply the primer, base color, and

finally, the enamel. To achieve the best

finish, apply two or three coats of primer.

Anti-corrosion

treatment

The entire car is corrosion-protected at the

factory in different stages by an electrolytic

immersion coating and a polyester-based

protective coating to protect against corro-

sion caused by stones flung up by the

wheels. A thin penetrating anti-rust oil is

also applied in cavities and body members.

In addition to conventional anti-corrosion

treatment like painting, underbody treat-

ment and cavity treatment, most of the body

panel surfaces are galvanized. These

include the hood, the doors and the under-

body.

The anti-corrosion treatment on the under-

side of the car and inside the wheel arches

is particularly exposed to constant wear and

possible damage, the degree of which will

obviously depend on driving conditions.

IB1334

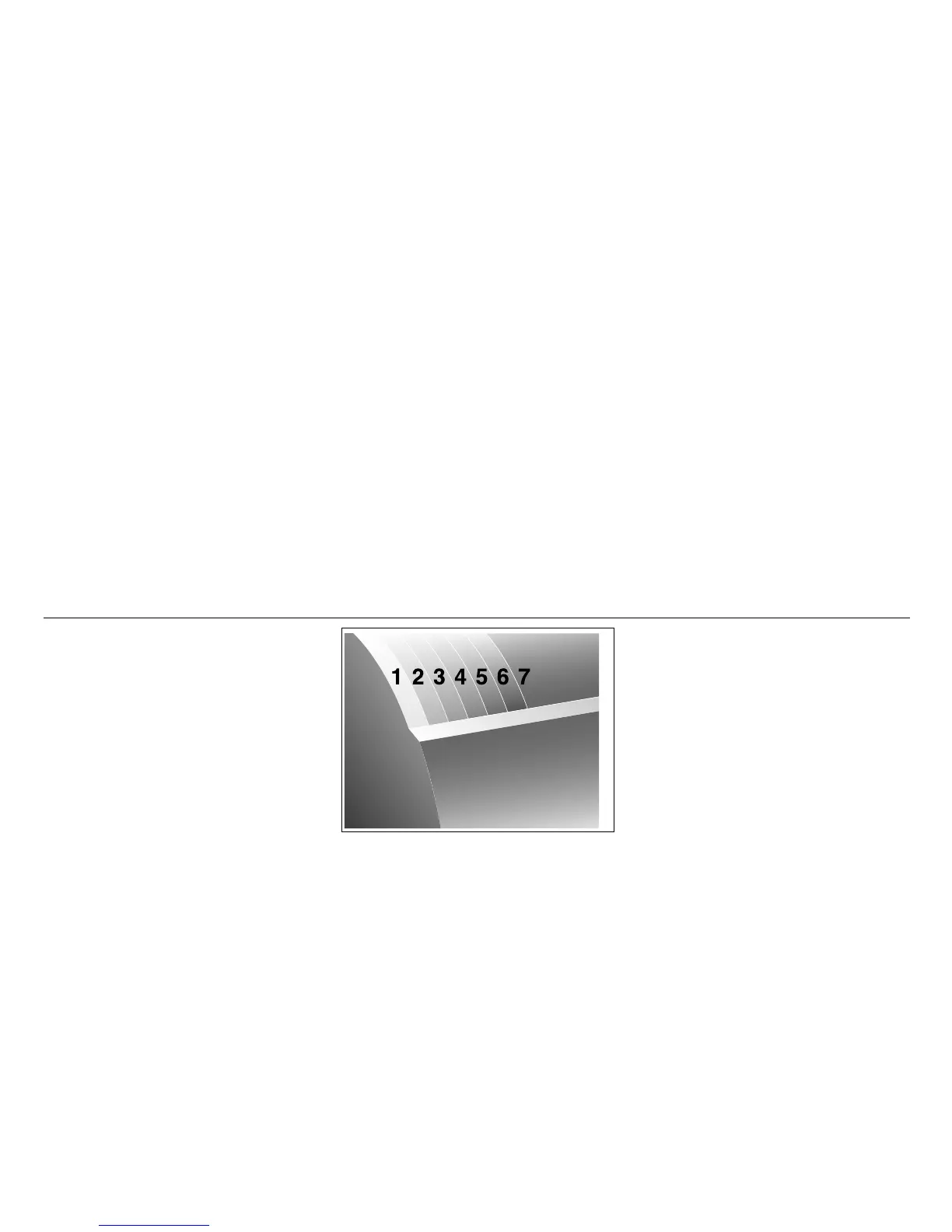

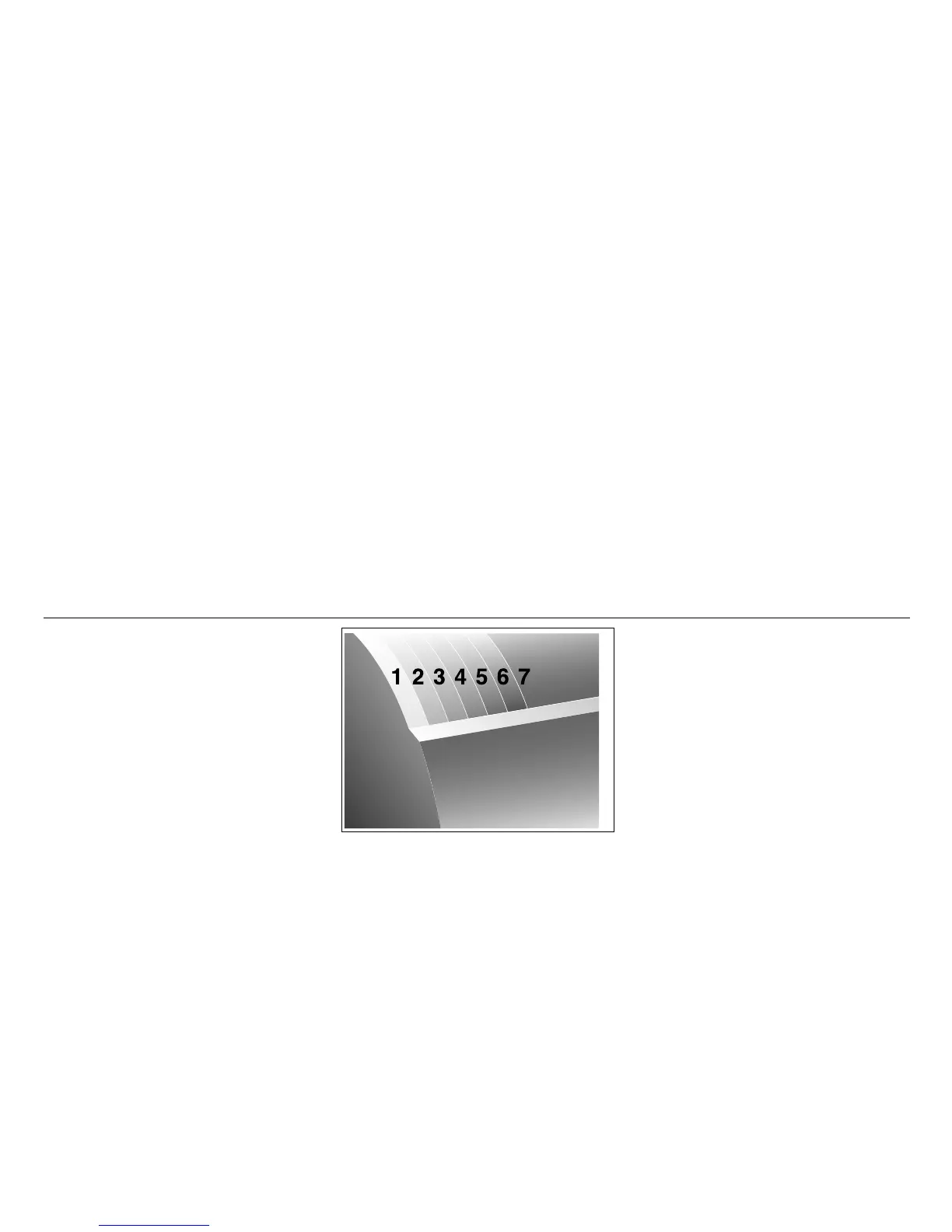

Surface-treatment composition

1 Body panel

2 Zinc (certain parts) 7.5 µm

3 Phosphate coating

4 Cathodic ED 28 µm

5 Intermediate coat 35 µm

6 Metallic base/solid base15 µm

7 Clear enamel 40 µm

Loading...

Loading...