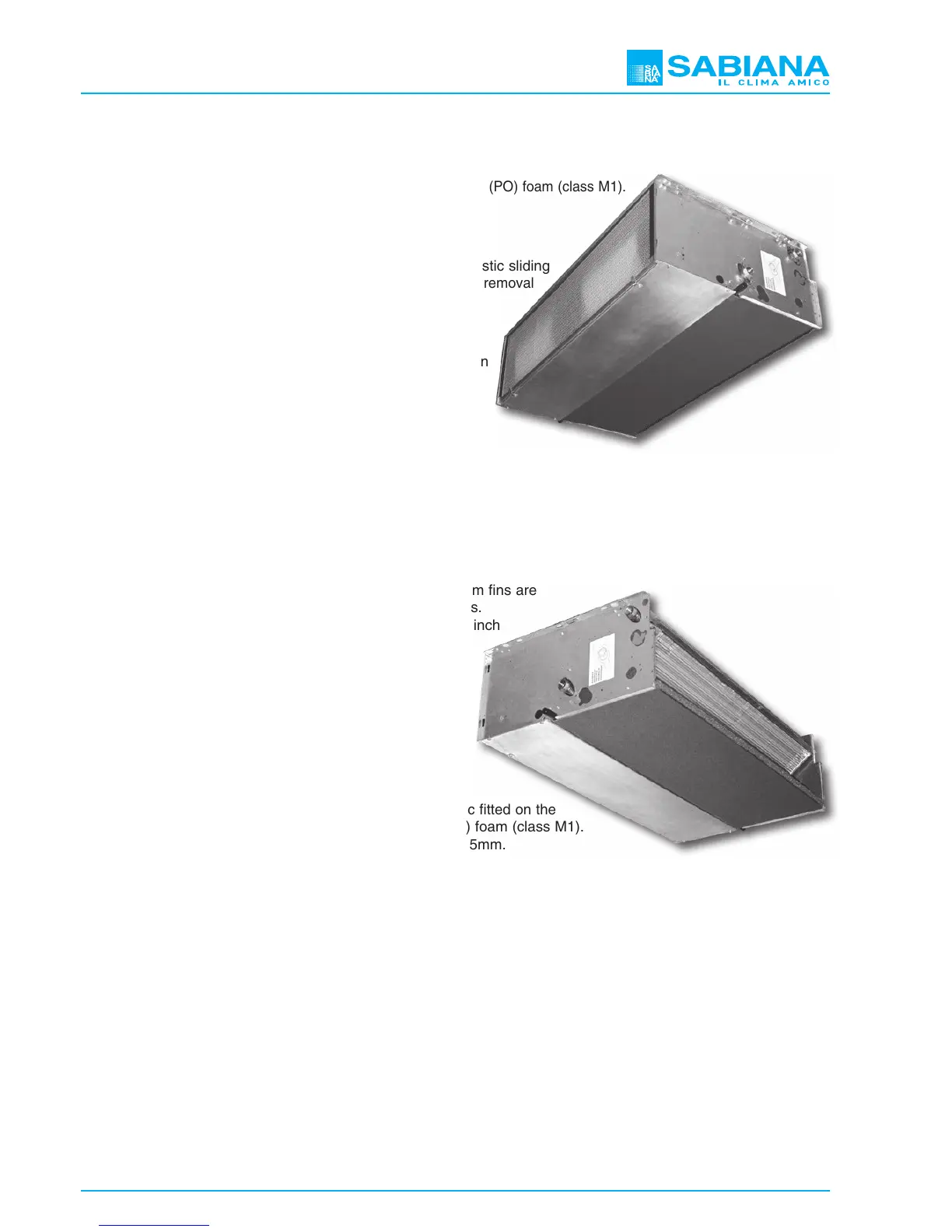

Casing

Made from 1 mm galvanized steel insulated with 3 mm polyolefin (PO) foam (class M1).

Filter

Polypropylene cellular fabric regenerating filter.

The filter frame of galvanized steel is inserted into special plastic sliding

guides fastened to the internal structure for easy insertion and removal

of the filter.

Fan assembly

The fans have aluminium or plastic blades directly keyed on

the motor with double aspiration and they are dynamically and

statically balanced during manufacture in order to have an

extremely quiet operation.

Electronic motor

Three phase permanent magnet brushless electronic motor that is controlled with reconstructed current according to

a BLAC sinusoidal wave. The inverter board that controls the motor operation is powered by 230 Volt, single-phase and,

with a switching system, it generates a three-phase frequency modulated, wave form power supply. The electric power

supply required for the machine is therefore single-phase with voltage of 230-240V and frequency of 50

-

60Hz.

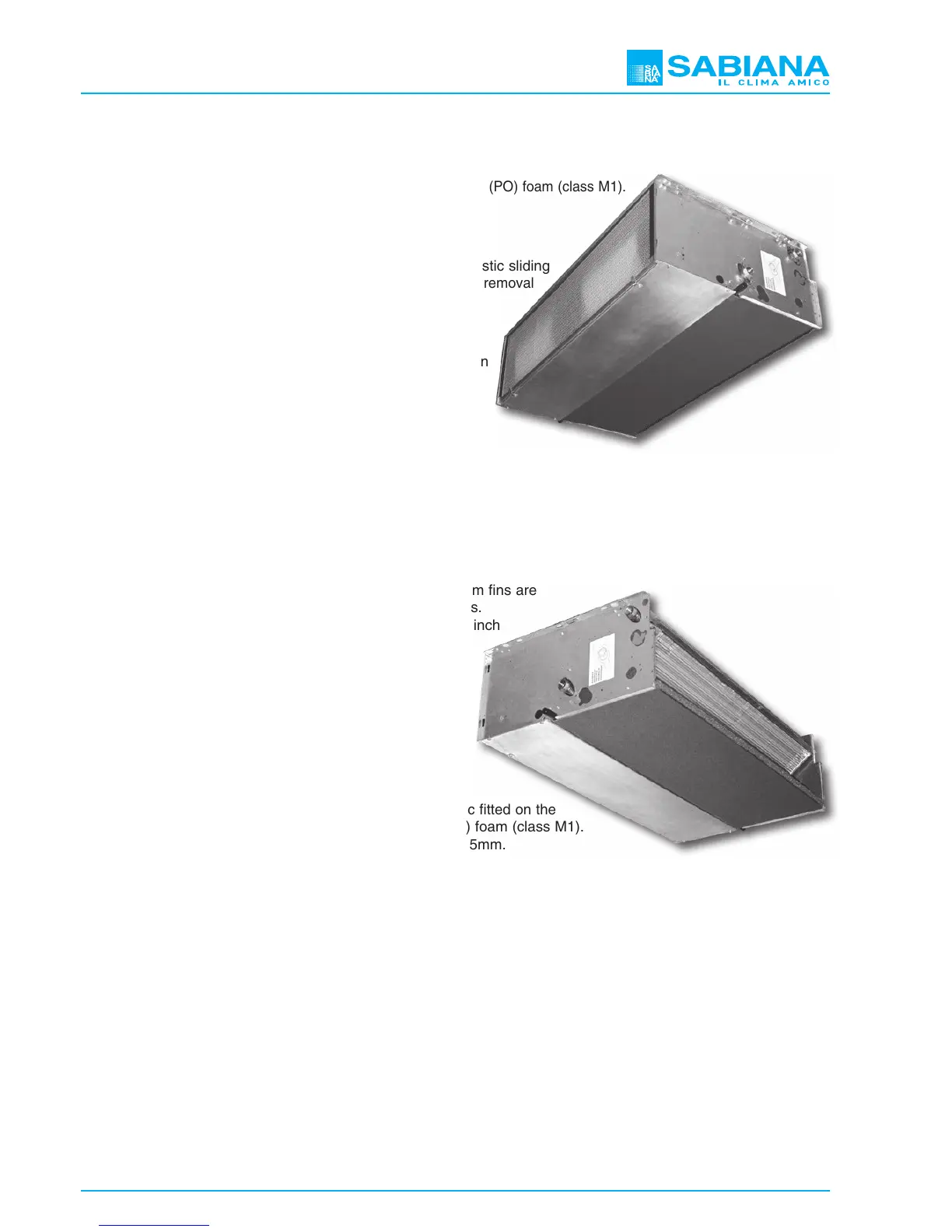

Coil

It is manufactured from drawn copper tube and the aluminium fins are

mechanically bonded onto the tube by an expansion process.

The coil has two 1/2 inch BSP internal connections and 1/8 inch

BSP air vent and drain.

The coil is not suitable for use in corrosive atmosphere or in

environments where aluminium may be subject to corrosion.

The connections are on the left hand side looking from the

air outlet of the unit (see picture).

On request or on site the connections can be moved

to the other side.

Condensate collection tray

Made from plastic (ABS UL94 HB) with an “L”-shaped plastic fitted on the

inner casing; the tray is insulated with 3 mm polyolefin (PO) foam (class M1).

The outside diameter of the condensate discharge pipe is 15mm.

Accessories and Controls

See pages 62

-

85.

Construction features

Loading...

Loading...