ENGLISH

ENGLISH

19

Under no circumstances should chlorine tablets be placed in the pre-filter basket.

The special key that is supplied to OPEN the pre-filter cover, should never be employed to close it.

When there is a frost risk, or when the pump is to remain off for any significant length of time, then it should

be emptied. This is accomplished by removing the two emptying plugs on the lower part of the pump body.

Apart from what has been stated above, our pumps do not require any other maintenance operations since the

bearings have been dimensioned and lubricated for life.

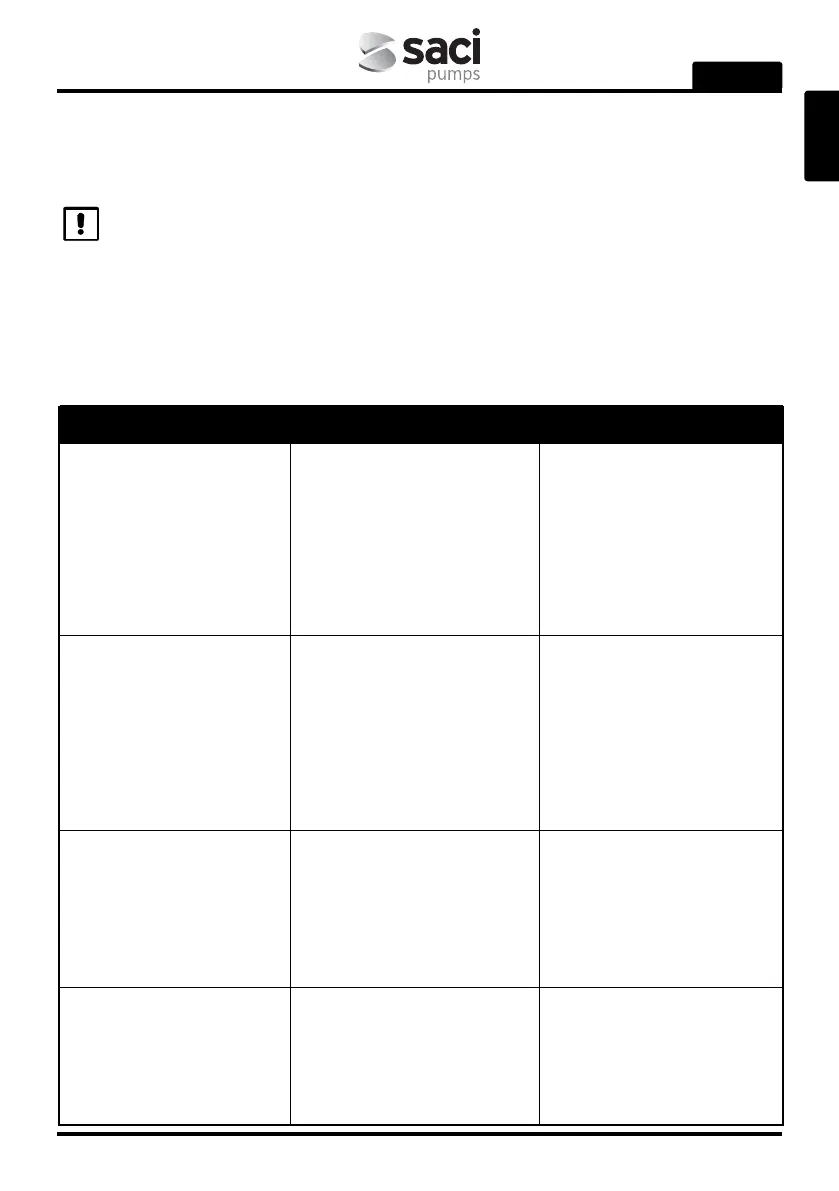

POSSIBLE FAULTS, THEIR CAUSES AND SOLUTIONS

• The pump will not prime

• The pump has not been primed

• Air entering by the suction piping

• Air entering via the mechanical seal

• Incorrectly closed pre-filter cover

• Excessive suction height

• Inverted motor rotation

• Incorrect voltage

• Air entering by the suction piping.

• Excessive suction height.

• Inverted motor rotation.

• Incorrect voltage.

• Blocked

• Suction piping diameter is less than

that required.

• Impulsion closed or blocked.

• Suction piping diameter is less than

that required.

• The pump or piping has not been

correctly secured.

• Inverted motor rotation

• Lack of mains supply.

• Breaker operation.

• Incorrect voltage.

• Motor jammed.

• Fill the pre-filter with water.

• Check the connections and piping.

• Replace the mechanical seal.

• Close correctly.

• Install at a suitable height.

• Invert two of the motor phases.

• Check the plate voltage.

• Check the connections and piping.

• Install at a suitable height.

• Invert two of the motor phases.

• Check the plate voltage.

• Clean the pre-filter basket.

• Correctly dimension the suction piping.

• Open the valve and check the sand

filter condition.

• Correctly dimension the suction piping.

• Recheck the pump and piping securing

methods so that they are separate.

• Invert two of the motor phases

• Check the voltage and fuses.

• Check and reset breaker.

• Check the plate voltage.

• Consult the Official Technical Service.

• The pump provides a poor flow rate

• The pump makes a lot of noise

• The pump will not start

FAULTS CAUSES SOLUTIONS

Loading...

Loading...